TM 5-818-5/AFM 88-5, Chap 6/NAVFAC P-418

ing surging, and recleaned after surging is completed.

g. After the wells are developed and satisfactorily

Material bailed from a well should be inspected to see

tested by pumping, the pumps, power unite, and dis-

if any foundation sand is being removed. It is possible

charge piping may be installed.

to oversurge a well, which may breach the filter with

h. Where drawdown or vacuum requirements in

resulting infiltration of foundation sand when the well

deep wells demand that the water level be lowered and

is pumped.

maintained near the bottom of the wells, the pumps

e. After a well has been developed, it should be

will have to handle a mixture of water and air. If such

pumped to clear it of muddy water and sand and to

a requirement exists, the pump bowls should be de-

check it for yield and infiltration. The well should be

signed to allow increasing amounts of air to enter the

pumped at approximately the design discharge from

bowl, which will reduce the efficiency of the pump un-

30 minutes to several hours, with periodic measure-

til the pump capacity just equals the inflow of water,

ment of the well flow, drawdown in the well, depth of

without cavitation of the impellers. The impellers of

sand in the bottom of the well, and amount of sand in

deep-well turbine pumps should be set according to the

the discharge. Measurements of well discharge and

manufacturer's recommendations. Improper impeller

drawdown may be used to determine the efficiency

settings can significantly reduce the performance of a

and degree of development of the well. The perfor-

deep-well pump.

mance of the well filter may be evaluated by measur-

5-3. Wellpoint systems.

ing the accumulation of sand in the bottom of the well

and in the discharge. A well should be developed and

a. Wellpoint systems are installed by first laying

pumped until the amount of sand infiltration is less

the header at the location and elevation called for by

than 5 to 10 parts per million.

the plans as illustrated in figure 5-1. After the header

pipe is laid, the stopcock portion of the swing connec-

f. Deep wells, in which a vacuum is to be main-

tion should be connected to the header on the spacing

tained, require an airtight seal around the well riser

called for by the design, and all fittings and plugs in

pipe from the ground surface down for a distance of 10

the header made airtight using a pipe joint compound

to 50 feet. The seal may be made with compacted clay,

to prevent leakage. Installation of the wellpoints gen-

nonshrinking grout or concrete, bentonitic mud, or a

erally follows layout of the header pipe.

short length of surface casing capped at the top. Im-

proper or careless placement of this seal will make it

b. Self-jetting wellpoints are installed by jetting

impossible to attain a sufficient vacuum in the system

them into the ground by forcing water out the tip of

to cause the dewatering system to operate as designed.

the wellpoint under high pressure. The jetting action

The top of the well must also be sealed airtight.

of a typical self-jetting wellpoint is illustrated in fig-

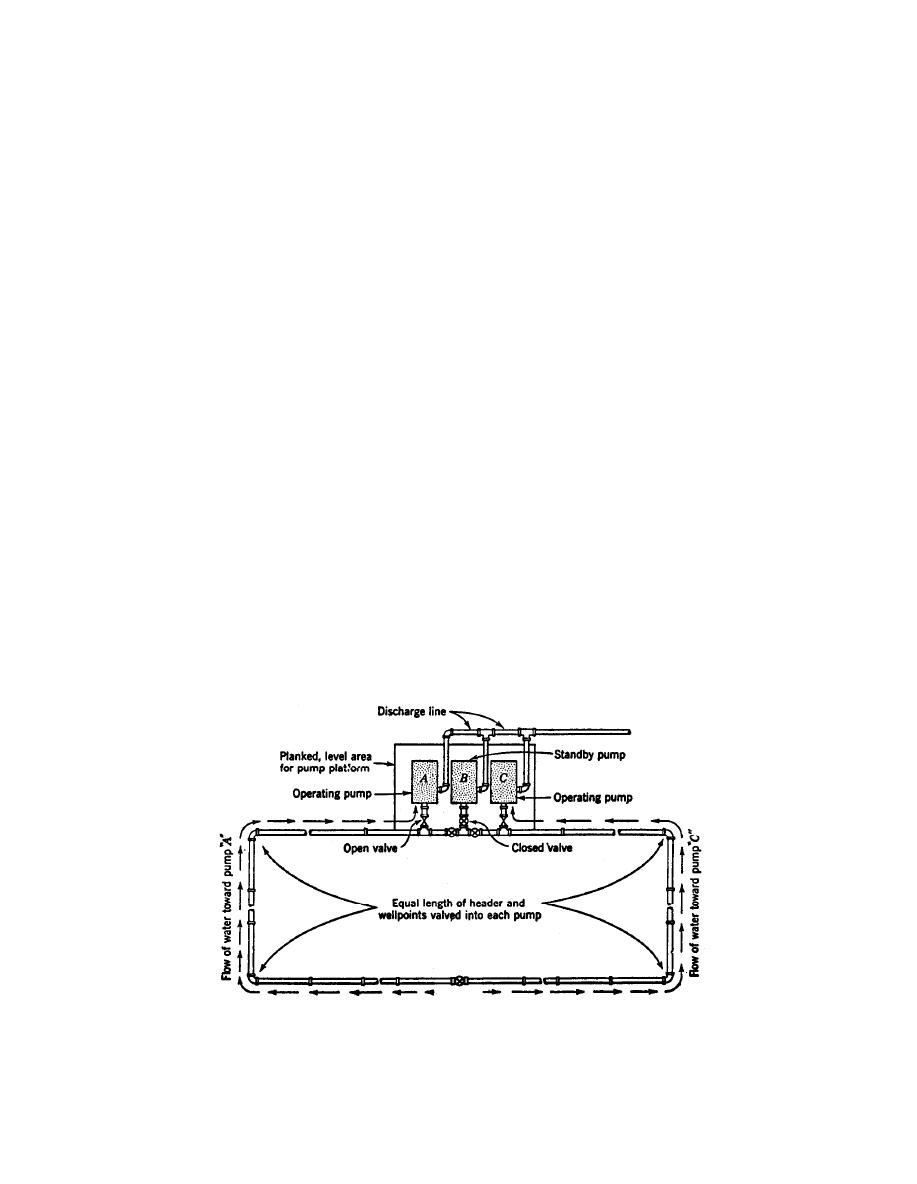

Plan of a typical wellpoint system.

(From "Foundation Engineering," G. A. Leonards, ed., 1962, McGraw-Hill Book

Company. Used with permission of McGraw-Hill Book Company.)

Figure 5-1. Plan of a typical wellpoint system.

5-2

Previous Page

Previous Page