TM 5-818-5/AFM 88-5, Chap 6/NAVFAC P-418

c. Steel sheet piling. Steel sheet pile cutoffs are con-

fill is required to ensure that the slurry is not trapped

structed employing the same general techniques as

within the backfill.

those used for driving steel sheet piles. However, pre-

(4) The backfill should be placed continuously as

cautions should be taken in handling and driving sheet

the trench is advanced. By so doing, sloughing of the

piling to ensure that the interlocks are tight for the

trench walls will be minimized, and the amount of ben-

full depth of the piling and that all of the sheets are

tonitic slurry required kept to a minimum. The level of

driven into the underlying impermeable stratum at all

the slurry in the trench should be maintained at least 5

locations along the sheet pile cutoff. Methods and

feet above the groundwater table. Care should be tak-

techniques for driving steel sheet piling are described

en to control the density and viscosity of the bentoni-

in numerous references on this subject.

tic slurry as required by the design. To minimize wast-

age of bentonitic slurry, it may be necessary to screen

d. Freezing. Freezing the soil around a shaft or tun-

out sand and gravel in order to reuse the slurry. (Con-

nel requires the installation of pipes into the soil and

struction techniques are still being developed.)

circulating chilled brine through them. These pipes

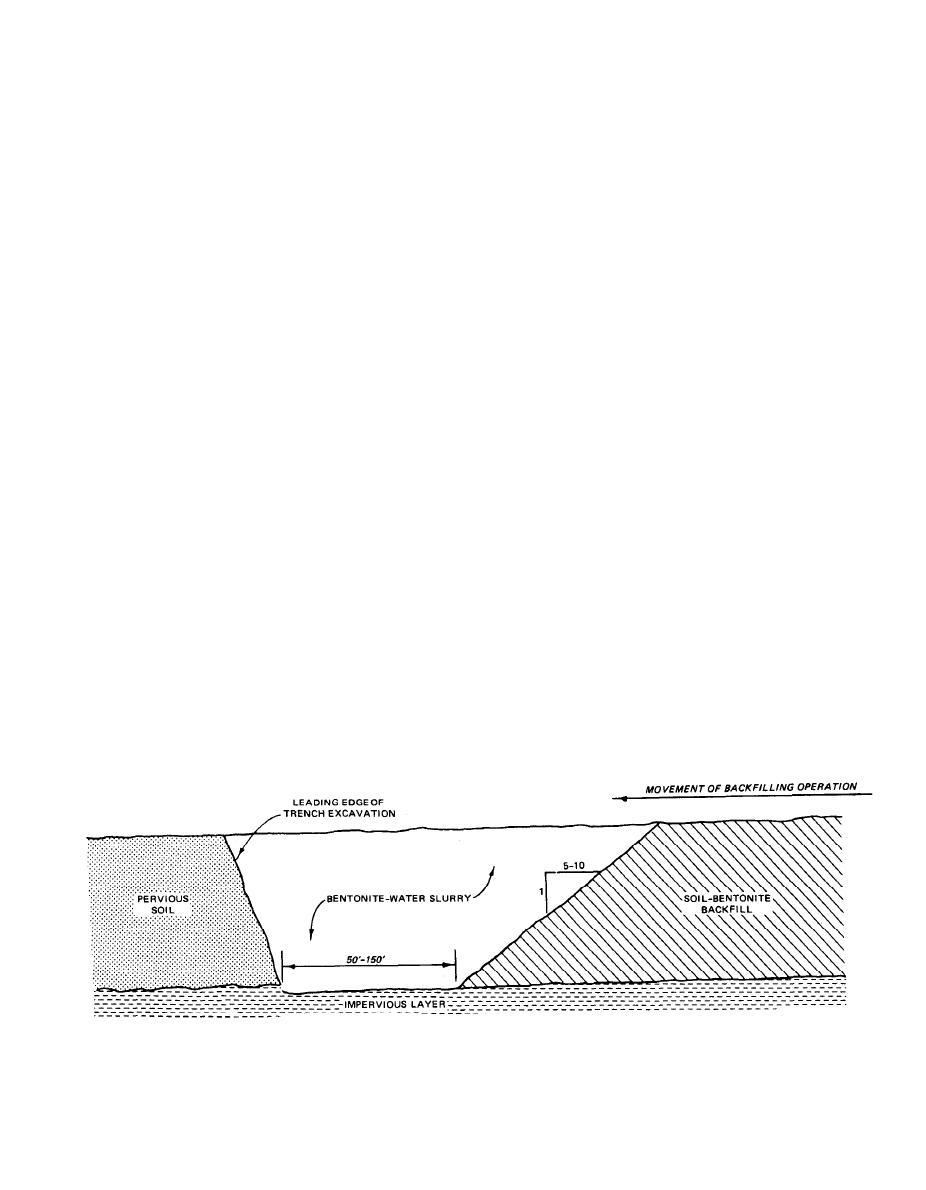

(5) The toe of the backfill slope should be kept

generally consist of a 2-inch inflow pipe placed in a

within 50 to 150 feet of the leading edge of the trench

6-inch closed-end "freezing" pipe installed in the

to minimize the open length of the slurry-supported

ground by any convenient drilling means. Two headers

trench. During placement operations, excavation and

are required for a freezing installation: one to carry

cleaning operations proceed simultaneously ahead of

chilled brine from the refrigeration plant and the oth-

the advancing backfill. (It should be noted that be-

er to carry the return flow of refrigerant. The refriger-

cause of the geometric constraints set by the backfill

ation plant should be of adequate capacity and should

slope, the amount of open trench length supported by

include standby or auxiliary equipment to maintain a

slurry is a function of the depth of the trench. For ex-

continuous operation.

ample, if the trench is 100 feet deep and the backfill

slope is 1V on 8H, the open length will be about 900 to

5-6. Piezometers.

950 feet-800 feet along the slope of the backfill face

a. Installation. Piezometers are installed to deter-

plus 100 to 150 feet from the backfill toe to the lead-

mine the elevation of the groundwater table (gravity

ing edge of the trench.)

or artesian) for designing and evaluating the perfor-

(6) When the trench is complete and the backfill

mance of a dewatering system. For most dewatering

occupies the entire trench, a compacted clay cap is nor-

applications, commercial wellpoints or small screens

mally placed over the trench. Key steps in this con-

are satisfactory as piezometers. The selection of well-

struction sequence involve the mixing of the bento-

point or screen, slot size, need for filter, and method of

nite-water slurry, excavation and stabilization of the

installation is the same for piezometers as for dewater-

trench, cleaning of the slurry, mixing of the soil-bento-

ing wellpoints. Holes for the installation of piezomet-

nite backfill, displacement of the slurry by the back-

ers can be advanced using continuous flight auger with

fill, and treatment of the top of the trench. Each of

a hollow stem plugged at the bottom with a removable

these items must be covered in the specifications.

U.S. Army Corps of Engineers

Figure 5-4. Installation of a slurry cutoff trench.

5-6

Previous Page

Previous Page