TM 5-818-5/AFM 88-5, Chap 6/NAVFAC P-418

are often wasted in construction; they are sometimes

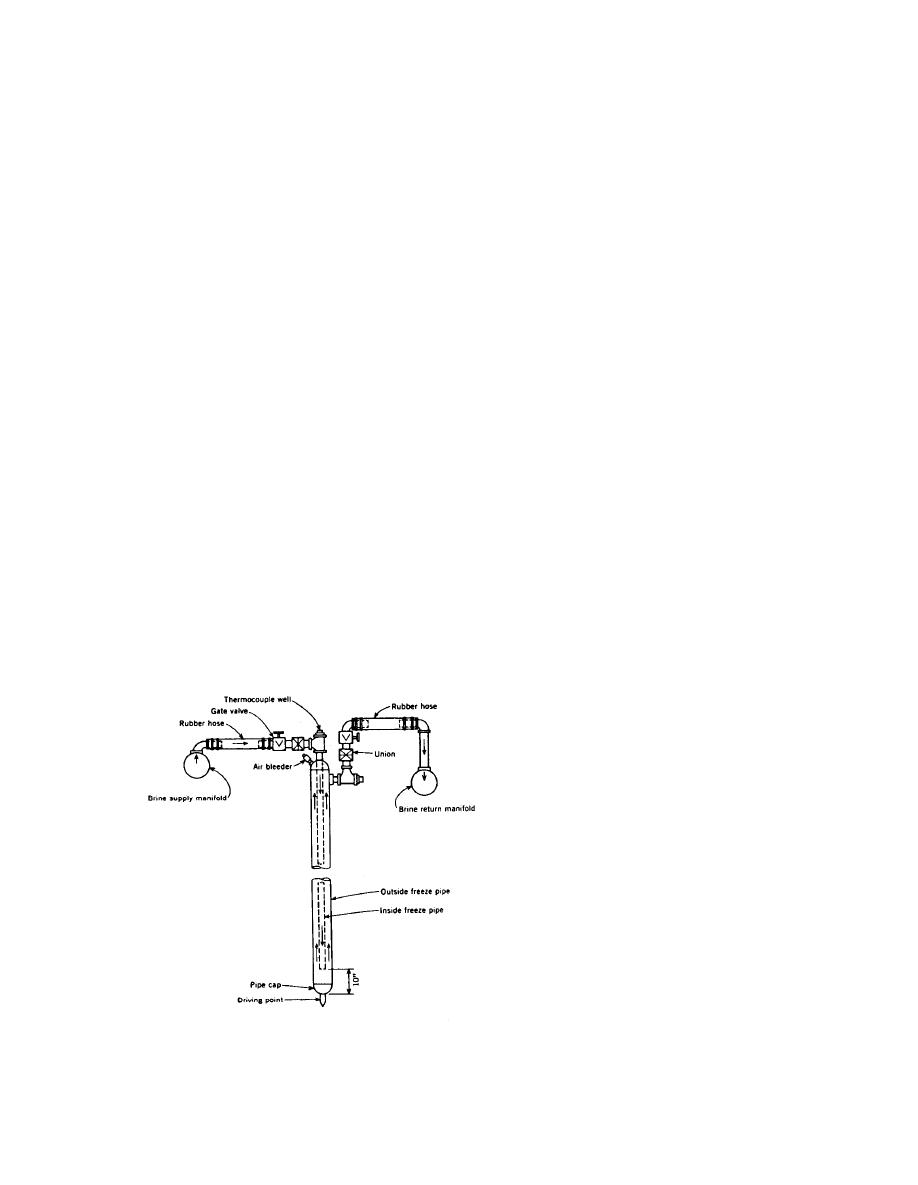

coolant flows slowly up the annulus between the pipes,

used for thawing the soil back to normal, in which case

pulls heat from the ground, and progressively freezes

they could be pulled afterward.

the soil. (A typical freeze-pipe is shown in fig. 4-37.)

After a week or two, the separate cylinders of frozen

d. Important considerations. The following items

soil join to form the barrier, which gradually thickens

must be considered when the freezing technique is to

to the designed amount, generally at least 4 feet (walls

be used:

of 24-foot thickness with two rows of freeze-pipes have

(1) Water movement in soil.

been frozen in large and deep excavations in soft or-

(2) Location of freeze-pipes. (The spacing of

ganic silts). The total freeze-time varies from 3 to 4

freeze-pipes should not exceed the designed amount by

weeks to 6 months or more but is predictable with high

more than 1 foot anywhere along the freeze wall.)

accuracy, and by instrumentation and observation the

(3) Wall closure. (Freeze-pipes must be accurately

engineer has good control. Sands of low water content

located, and the temperature of the soil to be frozen

freeze fastest; fine-grained soils of high water content

carefully monitored with thermocouples to ensure 100

take more time and total energy, although the refriger-

percent closure of the wall. Relief wells located at the

ation horsepower required may be greater than for

center of a shaft may also be used to check the prog-

sands.

ress of freezing. By periodically pumping these wells,

(2) The coolant is commonly a chloride brine at

the effectiveness of the ice wall in sealing off seepage

zero to -20 degrees Fahrenheit, but lower tempera-

flow can be determined.)

tures are preferable for saving time, reducing the

(4) Frost-heave effects-deformations and pres-

amount of heat to be extracted, and minimizing frost-

sures. (Relief wells may be used to relieve pressures

heave effects (which must be studied beforehand). In

caused by expansion of frozen soil.)

recent years, liquid propane at -45F has been used

(5) Temperature effects on buried utilities.

in large projects, and for small volumes of soil, liquid

(6) Insulation of aboveground piping.

nitrogen that was allowed to waste has been used.

(7) Control of surface water to prevent flow to the

(These cryogenic liquids demand special care-they are

freezing region.

dangerous.) Coolant circulation is by headers, com-

(8) Coolant and ground temperatures. (By moni-

monly 8-inch pipes, connected to a heat-exchanger at

toring coolant and soil temperatures, the efficiency of

the refrigeration plant using freon (in a modern plant)

the freezing process can be improved.)

as the refrigerant. The refrigeration equipment is us-

(9) Scheduling of operations to minimize lost time

ually rented for the job. A typical plant requires from

when freezing has been completed.

50 horsepower and up; 1000 horsepower or more has

(10) Standby plant. (Interruption of coolant circu-

sometimes been used. Headers should be insulated and

lation may be serious. A standby plant with its own

are recoverable. Freeze-pipes may be withdrawn but

prime movers is desirable so as to prevent any thaw. A

continuous advance of the freezing front is not neces-

sary so that standby plant capacity is much less than

that normally used.)

4-13. Control of surface water.

a. Runoff of surface water from areas surrounding

the excavation should be prevented from entering the

excavation by sloping the ground away from the exca-

vation or by the construction of dikes around the top

of the excavation. Ditches and dikes can be construct-

ed on the slopes of an excavation to control the runoff

of water and reduce surface erosion. Runoff into slope

ditches can be removed by pumping from sumps in-

stalled in these ditches, or it can be carried in a pipe or

lined ditch to a central sump in the bottom of the exca-

vation where it can be pumped out. Dikes at the top of

an excavation and on slopes should have at least 1 foot

of freeboard above the maximum elevation of water to

be impounded and a crown width of 3 to 5 feet with

side slopes of 1V on 2-2.5H.

(From "Tunnel Driven Using Subsurface Freezing. "by C. P. Gail, pp. 37-40.

Civil Engineering. American Society of Civil Engineers. May 1972.)

b. In designing a dewatering system, provision must

be made for collecting and pumping out surface water

Figure 4-37. Typical freeze-pipe.

4-49

Previous Page

Previous Page