TM 5-818-5/AFM 88-5, Chap 6/NAVFAC p-418

tem can be designed to lower the water table below the

with sand or weighting material added: The viscosity

tunnel or bottom of the shaft using methods and for-

of the slurry for excavating slurry wall trenches usual-

mulas presented in paragraphs 4-1 through 4-4. If the

ly ranges from a Marsh funnel reading of 65 to 90 sec-

soil or rock formation is stratified, the wells must be

onds, as required to hold any weighting material add-

screened and filtered through each pervious stratum,

ed and to prevent any significant loss of slurry into the

as well as spaced sufficiently close so that the residual

walls of the trench. The slurry should create a pressure

in the trench approximately equal to 1.2 times the ac-

head in each stratum being drained is not more than 1

or 2 feet. Dewatering stratified soils penetrated by a

tive earth pressure of the surrounding soil. Where the

shaft or tunnel by means of deep wells may be facili-

soil at the surface is loose or friable, the upper part of

tated by sealing the wells and upper part of the riser

the trench is sometimes supported with sand bags or a

pipe and applying a vacuum to the top of the well and

concrete wall. The backfill usually consists of a mix-

correspondingly to the filter. Maintenance of a vac-

ture of soil (or a graded mix of sand-gravel-clay) and

uum in the wells and surrounding earth tends to stabil-

bentonite slurry with a slump of 4 to 6 inches.

ize the earth and prevent the emergence of seepage in-

(3) Steel sheet piling. Seepage cutoffs may be cre-

to the tunnel or shaft.

ated by driving a sheet pile wall or cells to isolate an

c. In combined well-vacuum systems, it is necessary

excavation in a river or below the water table. Sheet

to use pumps with a capacity in excess of the maxi-

piles have the advantage of being commonly available

mum design flow so that the vacuum will be effective

and readily installed. However, if the soil contains cob-

for the full length of the well screen. Submersible

bles or boulders, a situation in which a cutoff wall is

pumps installed in sealed wells must be designed for

applicable to dewatering, the driving may be very dif-

the static lift plus friction losses in the discharge pipe

ficult and full penetration may not be attained. Also,

plus the vacuum to be maintained in the well. The

obstructions may cause the interlocks of the piling to

pumps must also be designed so that they will pump

split, resulting in only a partial cutoff.

water and a certain amount of air without cavitation.

(a) Seepage through the sheet pile interlocks

The required capacity of the vacuum pump can be esti-

should be expected but is difficult to estimate. As an

mated from formulas for the flow of air through por-

approximation, the seepage through a steel sheet pile

ous media considering the maximum exposure of the

wall should be assumed equal to at least 0.01 gallon

tunnel facing or shaft wall at any one time to be the

per square foot of wall per foot of net head acting on

most pervious formation encountered, assuming the

the wall. The efficiency of a sheet pile cutoff is sub-

porous stratum to be fully drained. The flow of air

stantial for short paths of seepage but is small or negli-

through a porous medium, assuming an ideal gas flow-

gible for long paths.

ing under isothermal conditions, is given in the follow-

(b) Sheet pile cutoffs that are installed for long-

ing formula:

term operation will usually tighten up with time as the

interlocks become clogged with rust and possible in-

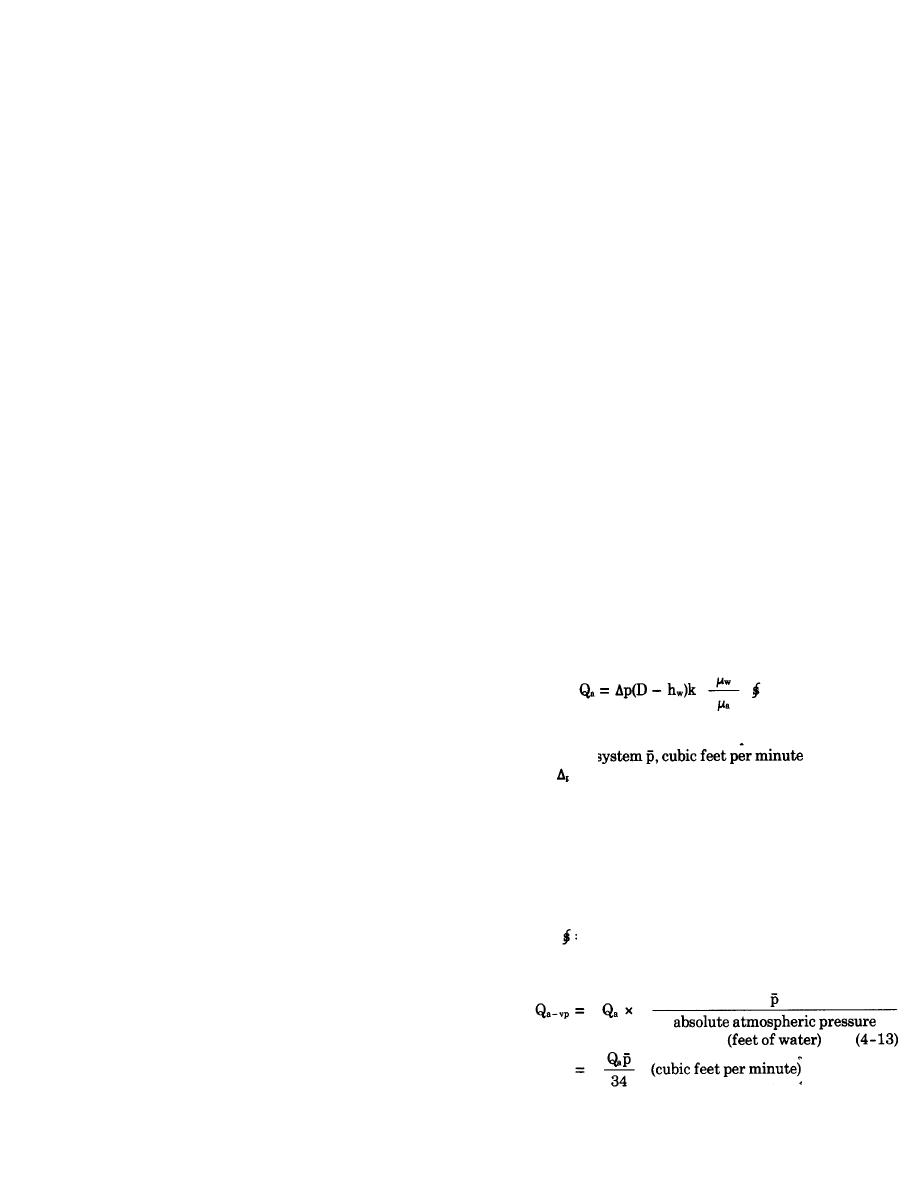

(4-12)

crustation by the groundwater.

(4) Freezing. Freezing the water in saturated por-

where

ous soils or rock to form an ice cutoff to the flow of

Qa = flow of air at mean pressure of air in flow

groundwater may be applicable to control of ground-

water for shafts or tunnels where the excavation is

pressure differential p1-p2) in feet of water

P=

small but deep. (See para 4-12 for information on de-

absolute atmospheric pressure

p1 =

sign and operation of freezing systems.)

absolute air pressure at line of vacuum wells

p2 =

D=

thickness of aquifer, feet

4-10. Dewatering shafts and tunnels.

hW =

head at well, feet

a. The requirements and design of systems for de-

coefficient of permeability for water, feet per

k=

watering shafts and tunnels in cohesionless, porous

minute

soil or rock are similar to those previously described

w =

absolute viscosity of water

for open excavations. As an excavation for a shaft or

absolute viscosity of air

a =

tunnel is generally deep, and access is limited, deep-

=

geometric seepage shape factor (para 4-3)

wells or jet-eductor wellpoints are considered the best

The approximate required capacity of vacuum pump is

method for dewatering excavations for such structures

expressed as

where dewatering techniques can be used. Grout cur-

tains, slurry cutoff walls, and freezing may also be

used to control groundwater adjacent to shafts or tun-

nels.

b. Where the soil or rock formation is reasonably

homogeneous and isotropic, a well or jet-eductor sys-

4-47

Previous Page

Previous Page