UFC 3-240-13FN

25 May 2005

little operator attention required. This does not mean that no attention is required, only

less than that required for medium-sized systems. The treatment program for small

systems is shown in Table 4-12.

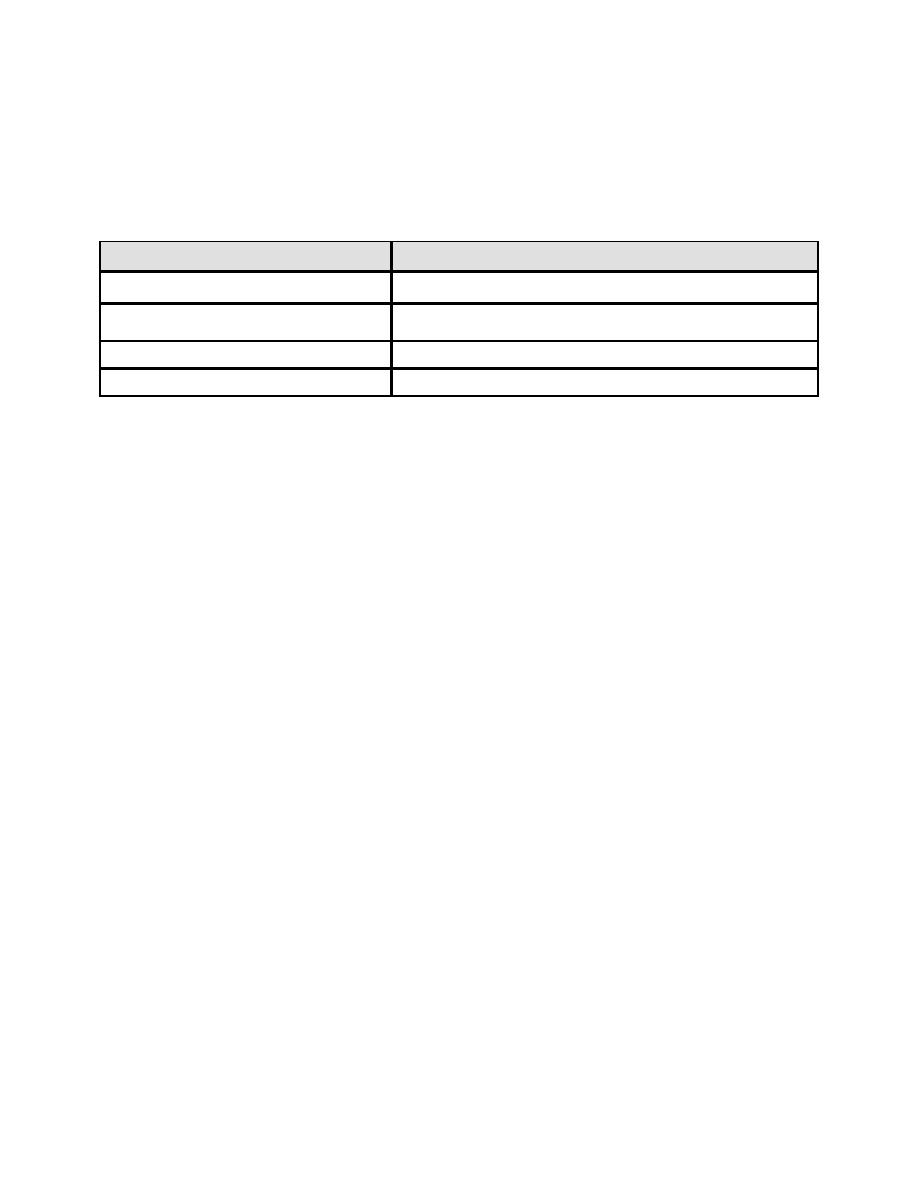

Table 4-12. Small Cooling Tower Treatment Program

Parameter

Method

Do not exceed COC limits for untreated water

COC

Dry slowly soluble phosphate compound

Scale and corrosion program

Microbiological program

Dry slowly soluble oxidizing biocide

SS

Filtration and periodic washdowns, as required

4-6.5.1

Treatment. Small systems can be treated with a low dosage (5 to 10 ppm)

of a slowly soluble phosphate chemical (sodium/calcium polyphosphate) by placing a

nylon mesh bag containing the product into the cooling tower. The product, if applied in

this manner, will usually provide adequate scale and corrosion control. Microbiological

control can be obtained by use of a dry, pelletized, oxidizing biocide, such as bromo-

chlorohydantoin or isocyanuric acid plus sodium bromide (see paragraph 4-4.4.1).

Either of these biocides can be fed continuously via a feeder or suspended in a mesh

bag in the cooling tower water. The cooling tower sump should be kept clean of SS and

other debris by use of a filter and periodic washdowns.

4-6.5.2

Testing. Testing is usually limited to assurance that the optimum COC

value is being maintained and that the chemical treatment agents are present in the

water. The bag with the chemical treatment should not be allowed to become less than

one-half full. The frequency for refilling the bag will vary; once every 1 to 2 months is

typical. Initially, the treatment level should be checked to assure that adequate, but not

excessive, levels of both phosphate and the biocide are present in the cooling water.

4-6.6

Treatment Program for Medium and Large Cooling Towers. The

chemical treatment program for these cooling tower systems (typically greater than 88

kilowatts [25 tons]) requires sufficient, regular testing as well as water and chemical

control to protect the equipment in contact with the cooling water. Usually treatment

includes control of scale, fouling, microbiological growth, and corrosion. The

composition of an optimum chemical treatment program for cooling towers on a military

installation depends on the quality of water available, the operating conditions of the

cooling system, and the environmental constraints placed on treatment chemicals in the

blowdown water (effluent discharge limitations). Conditions at a particular installation

may require variation of the quantity or mix of the chemicals suggested in Table 4-13.

134

Previous Page

Previous Page