UFC 3-240-13FN

25 May 2005

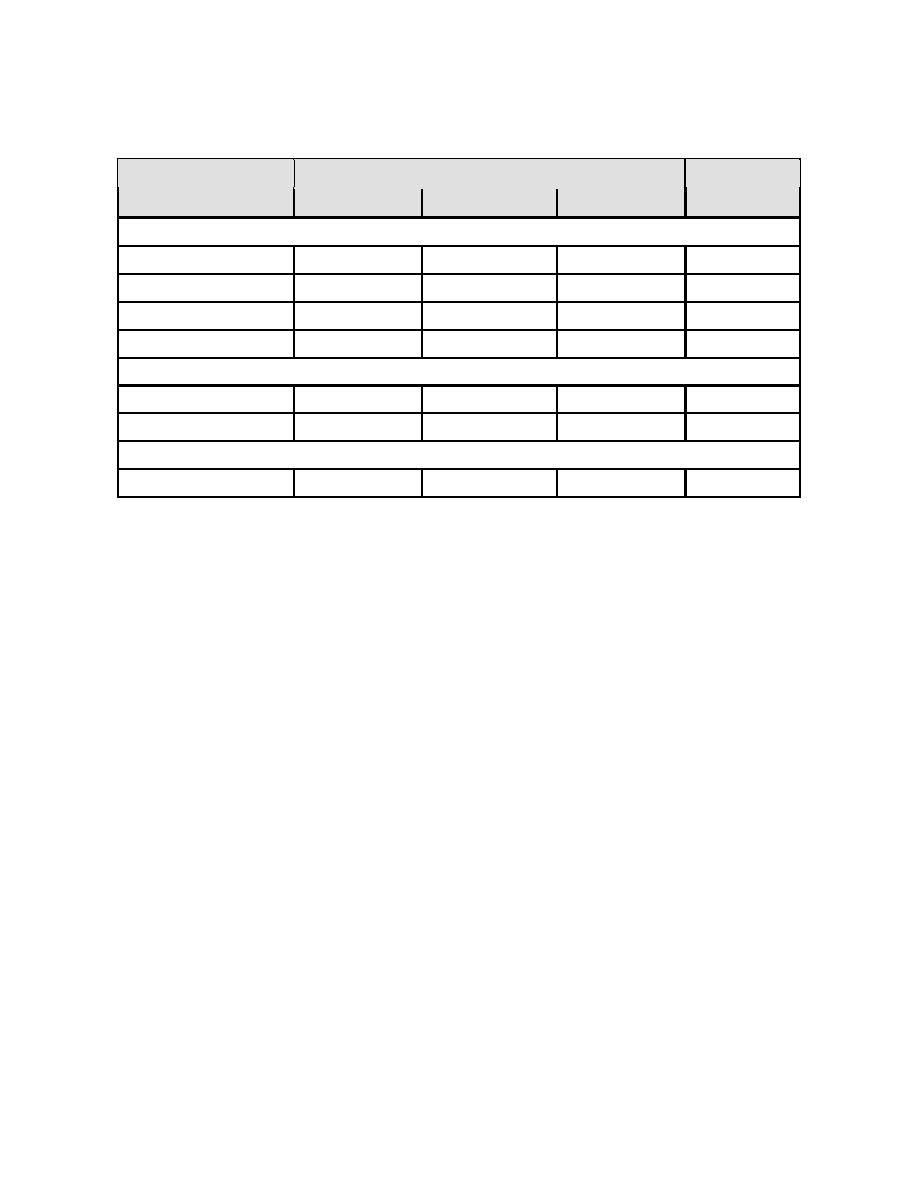

Table 4-10. Criteria for Corrosion Inhibitor Selection

Metal

Corrosion

pH Range

Inhibitor

(ideal)

Steel

Copper

Aluminum

Cathodic Inhibitor

Polyphosphate1

Excellent

Attacks

Attacks

6.5-8.5

Zinc salts2

Excellent

None

None

6.5-8.5

Polysilicate3

Excellent

Excellent

Excellent

7.5-10.0

Molybdate

Good

Fair

Fair

7.5-10.0

Anodic Inhibitor

Orthophosphate1

Good

Attacks

Attacks

6.5-8.5

Orthosilicate3

Good

Good

Good

7.5-10.0

Copper Corrosion Inhibitor

Azoles

Fair

Excellent

Fair

6.0-10.0

NOTES:

1. May require polymeric calcium phosphate dispersant.

2. Rarely used alone. Requires zinc solubilizer above pH 7.8.

3. Do not use if natural silica is 150 ppm or greater.

4-5.5.1

Effective Corrosion Control. Effective corrosion control requires

maintaining appropriate pH levels, plus adding maintenance dosages of chemical

corrosion inhibitors. Chemical corrosion inhibitors form a protective film or barrier on the

cooling system metal surfaces that have been cleaned prior to adding an initial high

dosage of inhibitor. The initial high dosage of inhibitor passivates (protects) the metal.

The appropriate dosage of corrosion inhibitor must be maintained continuously in the

cooling water to ensure continuing protection. Table 4-11 shows examples of various

passivation and maintenance dosage levels of corrosion inhibitors. Corrosion inhibitors

are divided into three classes: cathodic, anodic, and general filmers. Corrosion inhibitors

form a protective film on either the anode, the cathode, or over the entire metal surface.

The types of corrosion inhibitors are described below.

4-5.5.1.1

Anodic Inhibitors. Anodic inhibitors form a protective film coating on the

anodic metal (where the metal is lost) and thus directly control corrosion by preventing

the reaction that results in corrosion. Any unprotected areas will corrode at a much

faster rate than the protected areas, a factor that could result in pitting or localized

attack of the unprotected areas. Examples of anodic inhibitors include orthophosphate,

nitrite, and orthosilicates. Under certain conditions, molybdate can function as an anodic

inhibitor.

4-5.5.1.2

Cathodic Inhibitors. Cathodic inhibitors form a protective film coating of

the cathodic metal (where metal is not lost) and thus indirectly prevent corrosion by

interfering with the current flow required for the electrochemical reaction to proceed

130

Previous Page

Previous Page