UFC 3-240-13FN

25 May 2005

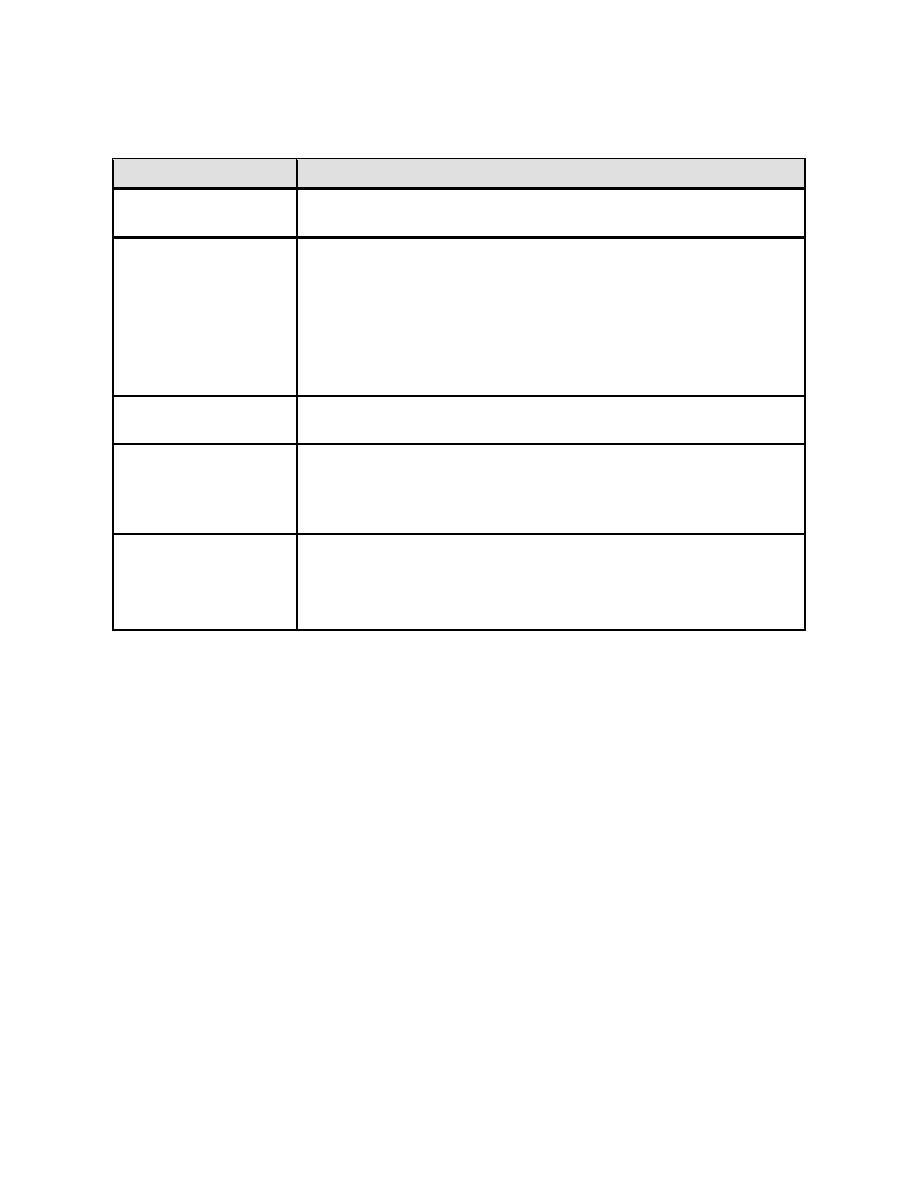

Table 4-13. Treatment Programs for Medium and Large Cooling Towers

Parameter

Approach

Target a minimum of 3 COC (ideally 5 COC) that the

COC

chemical treatment will allow.

1. Use of cathodic corrosion, possibly supplemented with

anodic inhibitors for mild steel. If a galvanized cooling tower

is present, use a polysilicate or low-level phosphate while

keeping pH in the range of 8 to 9.

Corrosion control

2. Copper corrosion inhibitor should be used for all copper

tubes and especially for enhanced and super-enhanced

copper tubing.

Phosphonate/polymer program, augmented by a phosphate

Scale control

dispersant if phosphate corrosion inhibitor is used.

Polymer dispersant coupled with adequate flow. Avoid no-

flow conditions in heat exchangers as much as possible.

SS

Mechanical filtration and routine physical sump cleaning

recommended.

1. Primary biocide: oxidizing biocide using continuous feed or

slug feed as an alternate.

Microbiological

control

2. Secondary biocide: non-oxidizing biocide using slug feed,

as required.

4-6.6.1

Treatment. Medium and large cooling towers are usually, but not always,

treated with a liquid formulation containing both scale inhibitors and corrosion inhibitors.

These are often simply referred to as an "inhibitor." Inhibitor products are usually fed on

a continuous basis using automated control and feed equipment. The concentration of

these formulated products varies greatly from vendor to vendor. Biocides are usually,

but not always, liquid products. It is common to use an oxidizing biocide as a primary

biocide and a non-oxidizing biocide as a secondary biocide, used as needed to control

bacteria and other biological growth. Oxidizing biocides can either be fed continuously

at a low level or dosed periodically at a higher level. Non-oxidizers are dosed as needed

and only when oxidizing biocides are either ineffective or not used at all.

4-6.6.2

Testing. Testing should be done regularly to insure that COC, chemical

levels, and bacteria levels are within the targeted control range. This requirement could

demand a testing frequency of 3 times per week, or even daily.

4-6.7

Cooling Tower Operator Duties. If detected early, problems associated

with scaling, corrosion and fouling in a cooling tower system can be minimized by

corrective action. Some of the things the operator should look for when on-site are

described below.

135

Previous Page

Previous Page