UFC 3-240-13FN

25 May 2005

d) Fill the system with makeup water and circulate for 30 minutes.

e) Take a sample of system water while it is circulating. The sample should

match the makeup water supply for clarity and SS; conductivity 10%; and

pH 0.3 pH units from 7.5 to 8.5.

If necessary, repeat steps a) through e) until the system water matches this

description. The system should now be clean and passivated.

4-7.3.2.3

Chemical Cleaning and Passivation Formulation. Apply this chemical

cleaning and passivation formulation when the water system pH is 7.5 to 8.5; adjust pH

as required. Formulation limitations may require adding separate components to keep

things in solution. Other formulations may be used.

Orthophosphate (or) hexametaphosphate (as PO4): 60 ppm

Polyacrylate (active): 20 ppm

Tolyltriazole (active): 10 ppm

Sodium gluconate: 50 ppm

Pluronic L-61 (active) (non-ionic surfactant with antifoam): 400 ppm

Phosphate scale inhibitor: 50 ppm

4-7.3.2.4

Passivation of the System. Supplemental corrosion inhibitors may be

used in conjunction with the phosphate but are not required. Maintain and circulate the

levels for the time required. After passivation, proceed to operational readiness or layup

as required. Tables 4-14 and 4-15 show chemical technology used for passivation.

4-7.3.2.5

Operational Readiness. If system operation is not required for a period of

a week or more, proceed to layup. For normal operation, allow corrosion inhibitor levels

to subside to maintenance levels through normal blowdown. Proceed to maintenance

water treatment program.

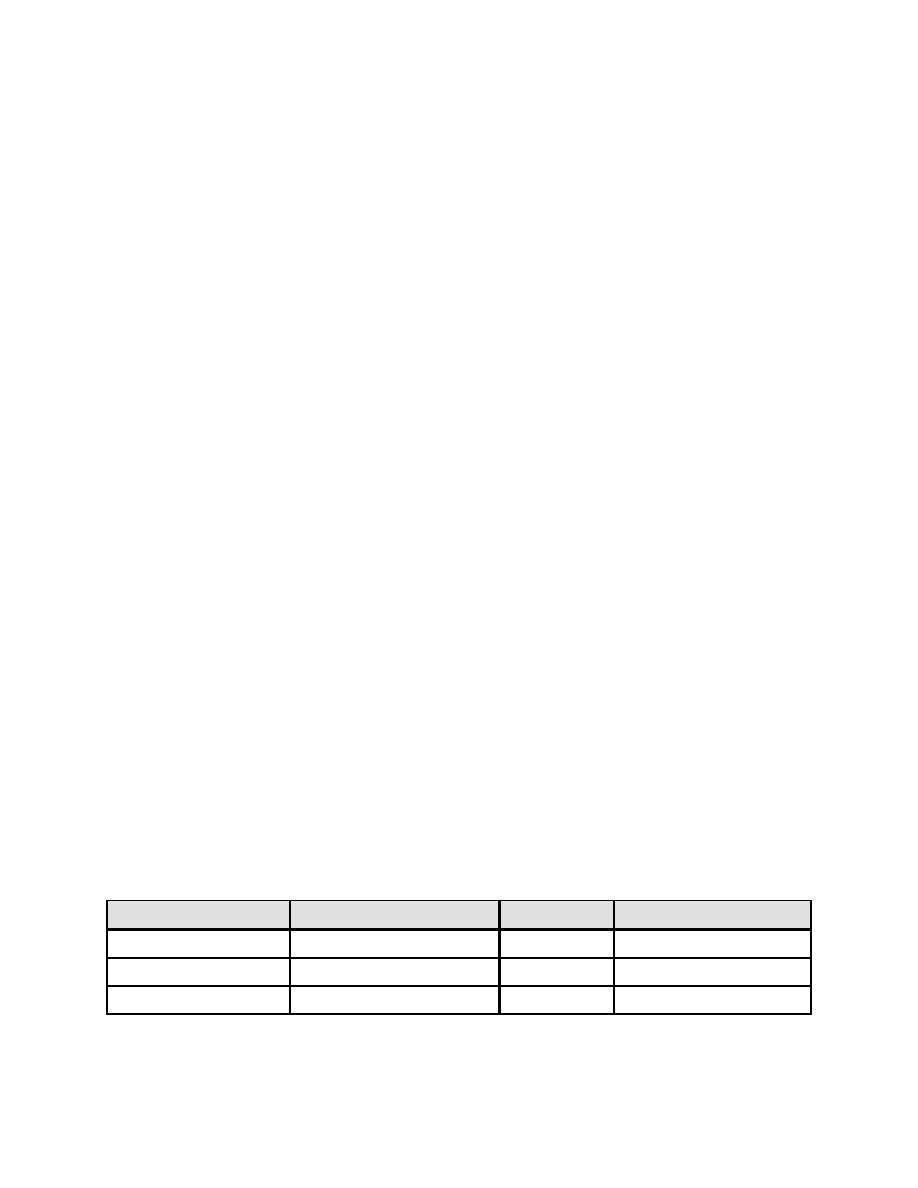

Table 4-14. Required Chemical Technology

Film Formation

Inhibitor

Dosage

pH

Polyphosphate

40-60 ppm as PO4

6.5-7.9

14-21 days

Orthophosphate

20-30 days as PO4

6.5-7.9

14-21 days

Tolytriazole

10-20 days as TTA

6.5-7.9

14-21 days

139

Previous Page

Previous Page