UFC 3-240-13FN

25 May 2005

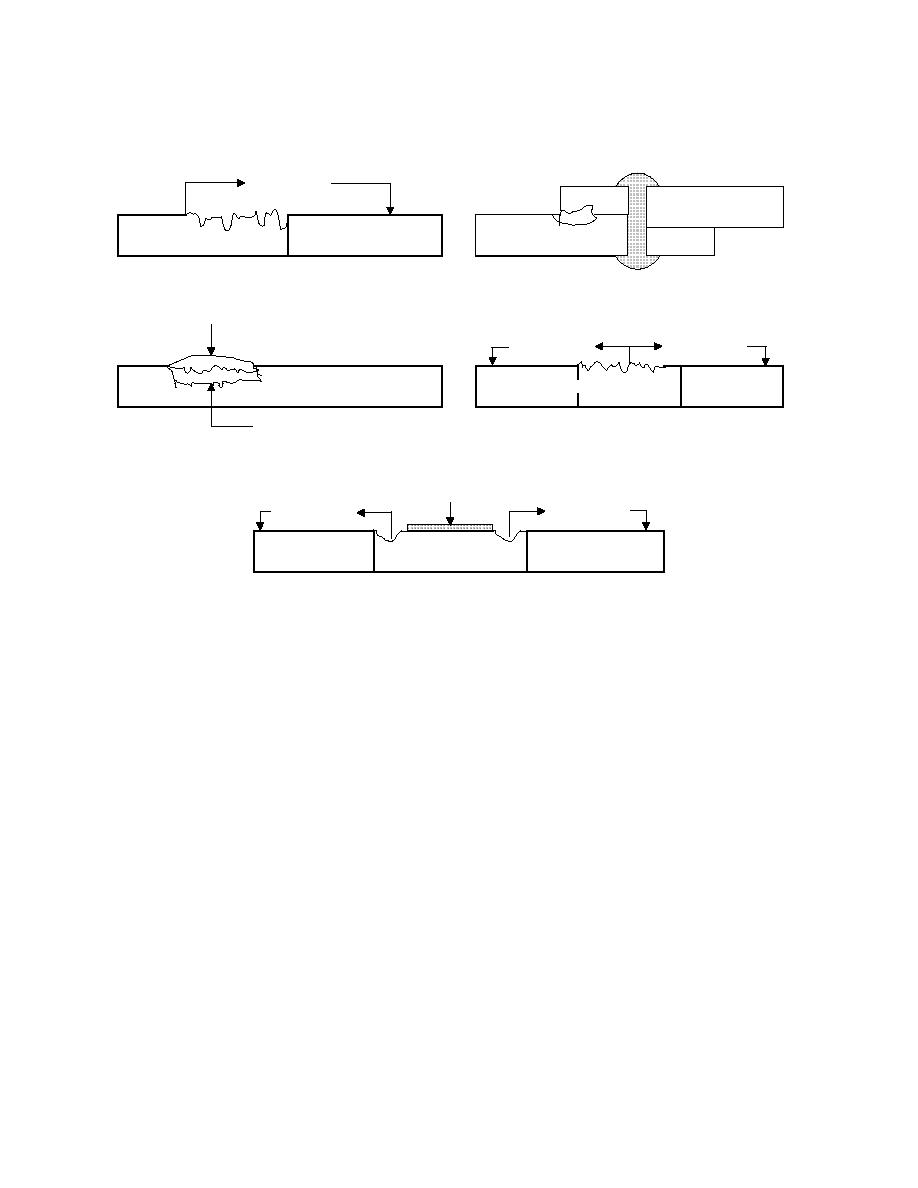

Figure 4-17. Forms of Corrosion

Current Flow

Steel

Steel

Copper

Steell

Stee

(A) Galvanic Corrosion

(B) Crevice Corrosion

Deposit

Current Flow

Current Flow

Cathode

Anode

Cathode

Corrosion

(C) Deposit Corrosion

(D) General Corrosion

Inhibitor

Film

Current Flow

Current Flow

Cathode

Cathode

Pit

Pit

Anode

(E) Pitting Attack

4-5.1

Galvanic Corrosion. See Figure 4-17 (A). This term refers to corrosion

that occurs when two different metals are coupled together. The metal with the least

resistance becomes the anode and will corrode due to the electrochemical reaction

produced. One of the most common instances of galvanic corrosion occurring in cooling

water systems results when mild steel and copper alloy metals are brought into contact

with one another (e.g., copper tubing attached to a mild steel tube sheet or brass valves

connected to mild steel or galvanized piping). As a result of the electrochemical

reaction, the copper is dissolved in the water and corrosion of copper alloy results. The

copper can also plate out (stick) on mild steel surfaces, setting up additional galvanic

cells. Another example is the electrochemical reaction that occurs when mild steel and

zinc (galvanizing) are coupled together at temperatures normally found in cooling tower

systems. The zinc becomes the anode and is corroded. Figure 4-18 shows the galvanic

series. Any coupling of a metal that is higher in the galvanic series with a metal or alloy

that is lower in the galvanic series results in electrochemical reaction in which the

"higher" metal functions as the anode or active metal.

125

Previous Page

Previous Page