UFC 3-240-13FN

25 May 2005

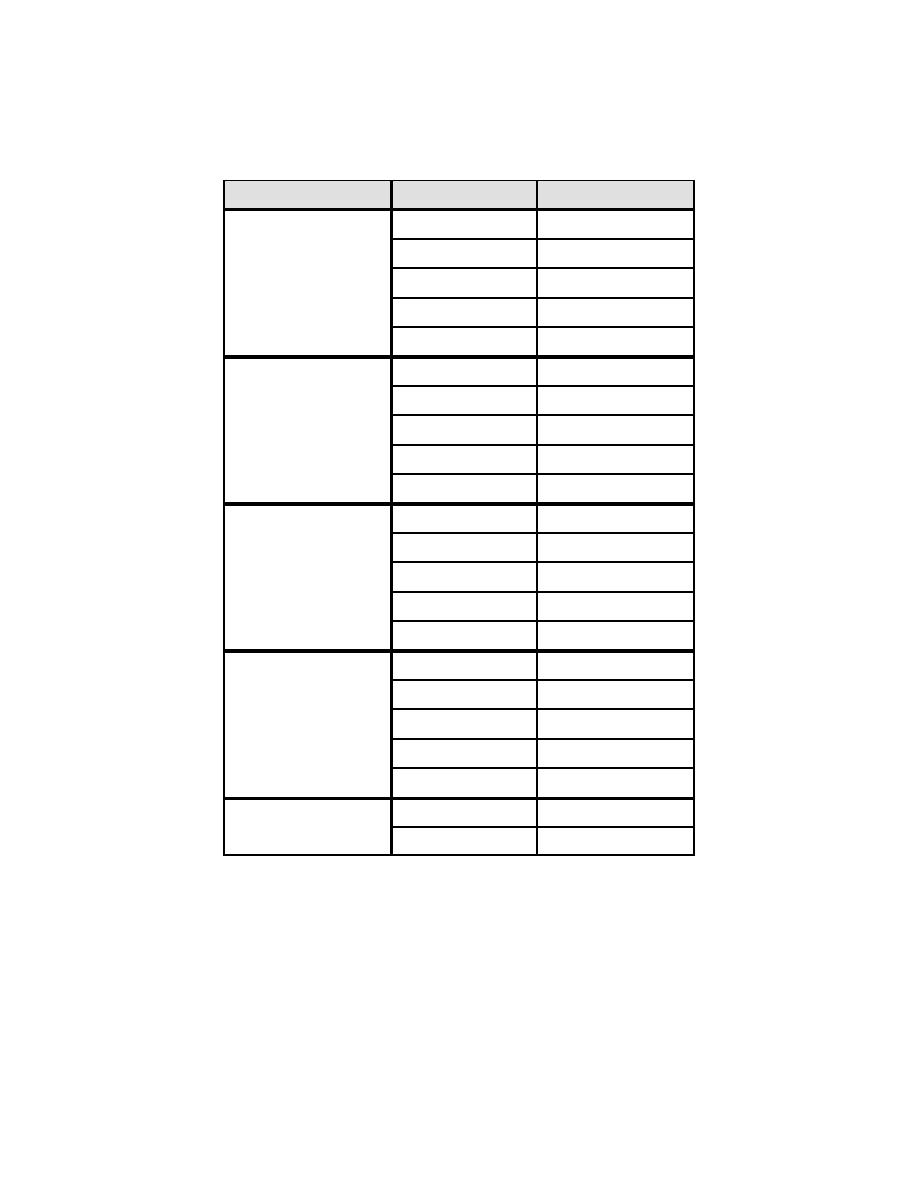

Table 4-9. Assessing Corrosion Rates in Cooling Water Systems:

90-Day Corrosion Coupon Test

Metal

mpy

Comment

<1

Excellent

> 1 to 3

Good

Mild steel piping

> 3 to 5

Fair

> 5 to 10

Poor

> 10

Unacceptable

Excellent

< 0.2

Good

> 0.2 to 0.5

Mild steel Hx

Fair

> 0.5 to 1.0

tubing

Poor

> 1.0 to 1.5

Unacceptable

> 1.5

< 0.1

Excellent

> 0.1 to 0.2

Good

Copper and

> 0.2 to 0.3

Fair

copper alloys

> 0.3 to 0.5

Poor

> 0.5

Unacceptable

<2

Excellent

> 2 to 4

Good

Galvanized steel

> 4 to 8

Fair

> 8 to 10

Poor

> 10

Unacceptable

< 0.1

Acceptable

Stainless steel

> 0.1

Unacceptable

NOTE: Determine pitting on coupons by visual observation; any pitting is unacceptable.

4-5.5

Corrosion Control Methods. In cooling water systems, two basic

techniques are used to provide corrosion protection to the metals that the water

contacts: use of chemical corrosion inhibitors, and raising the pH of the cooling water.

Figure 4-19 illustrates the effect of pH on the corrosion rate of mild steel. Most military

cooling water systems contain components fabricated primarily of copper alloy and mild

steel. Galvanized steel is present in galvanized cooling towers and stainless steel may

be present in piping. As the cooling water pH is increased (ideally to within the range of

8.0 to 9.5), copper and mild steel corrosion rates will decrease as shown in Figure 4-19,

although very high pH levels are corrosive to copper. The increase in pH alone cannot

128

Previous Page

Previous Page