TM 5-805-12

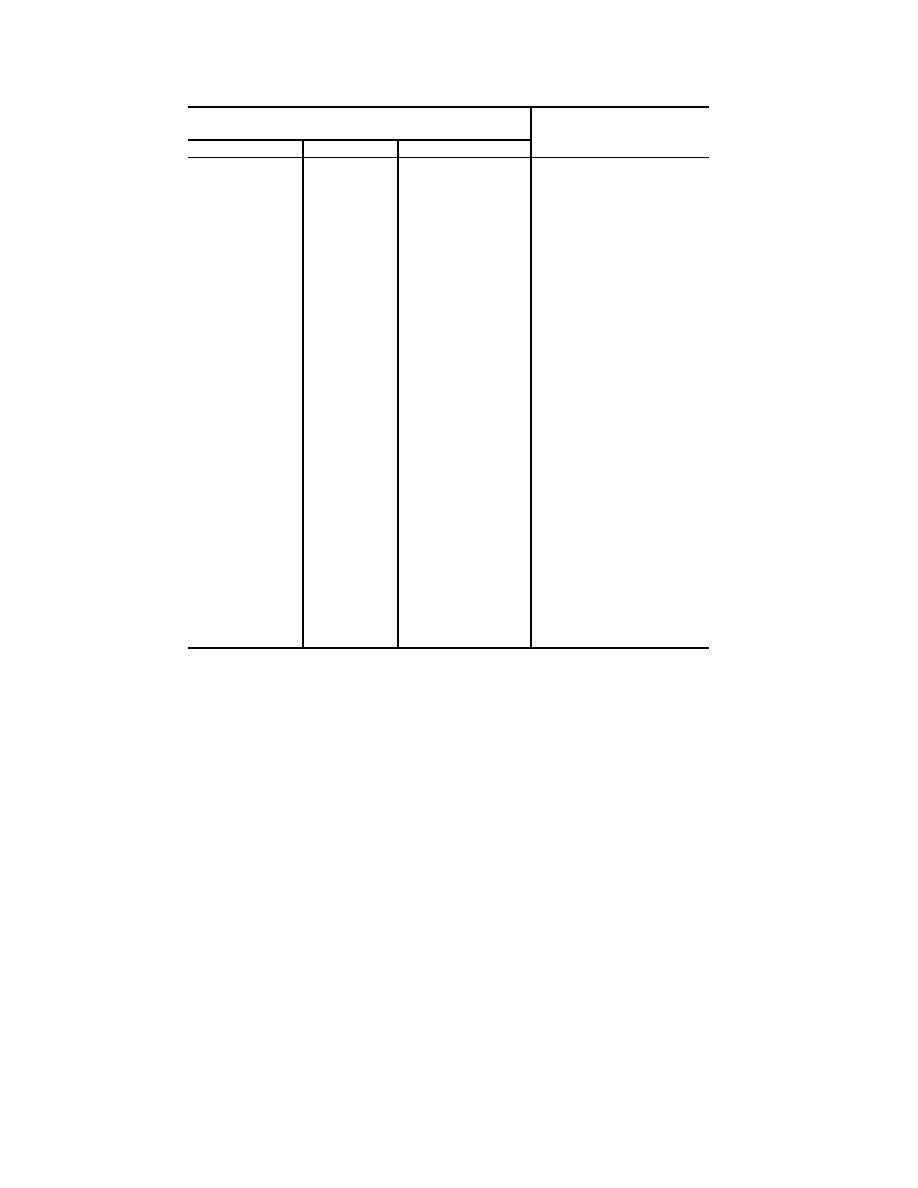

Table 4. Lead shielding conversions.

APPROXIMATE WEIGHT

THICKNESS

3

MILLIMETERS

INCHES

DECIMAL INCHES

POUND/FT

0.20

1/128

0.0078

0.5

0.40

1/64

0.0158

1.0

0.60

3/128

0.0234

1.5

0.79

1/32

0.0313

2.0

1.00

5/128

0.0391

2.5

1.19

3/64

0.0469

3.0

1.39

7/128

0.0547

3.5

1.58

1/16

0.0625

4.0

1.98

5/64

0.0781

5.O

2.38

3/82

0.0938

6.0

3.17

1/8

0.1250

8.0

3.97

5/32

0.1563

10.0

4.76

3/18

0.1875

12.0

5.56

7/32

0.2187

14.0

6.35

1/4

0.2500

16.0

7.14

9/32

0.2813

16.5

7.94

5/16

0.3125

18.0

8.47

1/3

0.3333

20.0

8.73

11/32

0.3834

20.5

9.53

3

0.3750

22.0

10.76

2/5

0.4000

24.0

11.11

7/16

0.4375

26.0

12.70

1/2

0.5000

30.0

14.29

/16

0.5625

33.0

15.88

5/8

0.6250

37.0

16.93

2/3

0.6667

40.0

17.46

11/16

0.6875

41.0

19.05

3/4

0.7500

45.0

20.64

13/16

0.8125

48.0

22.23

7/8

0.8750

52.0

23.81

15/16

0.9375

55.0

25.40

1

1.000

60.0

Source: Management and control of Diagnostic X-Ray, Therapeutic X-Ray, and Gamma-Beam equipment, TB MED 521.

bonded under pressure to plywood, gypsum plaster lath, gypsum wall board, aluminum, or steel. Lead panels can be

fastened with common nails or common screws that are covered with a lead tab, grommet, and/or a lead disk depending

on whether the studs or furring strips are wood or metal. See figure 1 for details.

a. Lead-lined wallboard. Lead-lined wallboard consists of a sheet of unpierced lead laminated to gypsum

wallboard. The standard wallboard size is 1/2 or 5/8 inch thick, 48 inches wide, and 96 inches long. See figure 2 for

jointing details.

(1) Pilot holes for lead-headed nails are predrilled or field drilled as necessary to prevent deformation of the

lead-headed nail and distortion of the wallboard.

(2) Wallboard is applied with long edges parallel to supports and with lead linings placed next to supports.

Blocking is provided at end joints. Sheet-lead strips not less than the thickness used on the wallboard and not less than 1-

1/2 inches wide are installed on blocking and supports where joints occur. The lead strips are secured to blocking and

supports with wire nails at outer edges of strips. Edges of the wallboard are butt-jointed and nailed to supports with nails

at approximately 8 inches on centers at joints and 12 inches on centers at intermediate supports. The nails are driven

slightly below the surface of the wallboard and then covered with a 5/16-inch diameter lead disk. Lead disks are covered

by tape or spackling to hold them in place.

(3) When using screws to attach wallboard to metal studs, they must be 1 inch long and used at the edges of

the board. Heads of screws are covered with a 1/2-inch diameter lead disc cemented to wallboard and made flush with

the surface of the wallboard.

(4) When using two layers of wallboard, the finish ply is to be bonded to the first ply with a laminating adhesive

that is applied following the manufacturer's recommendations. First ply of wallboard is nailed to supports with a nail

covered with a 5/8-inch diameter lead disk. Nailing of the finish ply will not be permitted. A shoring system will be used to

hold the finish ply in place until the adhesive dries; a minimum of 24 hours.

1-6

Previous Page

Previous Page