TM 5-805-12

Figure 3. Lath.

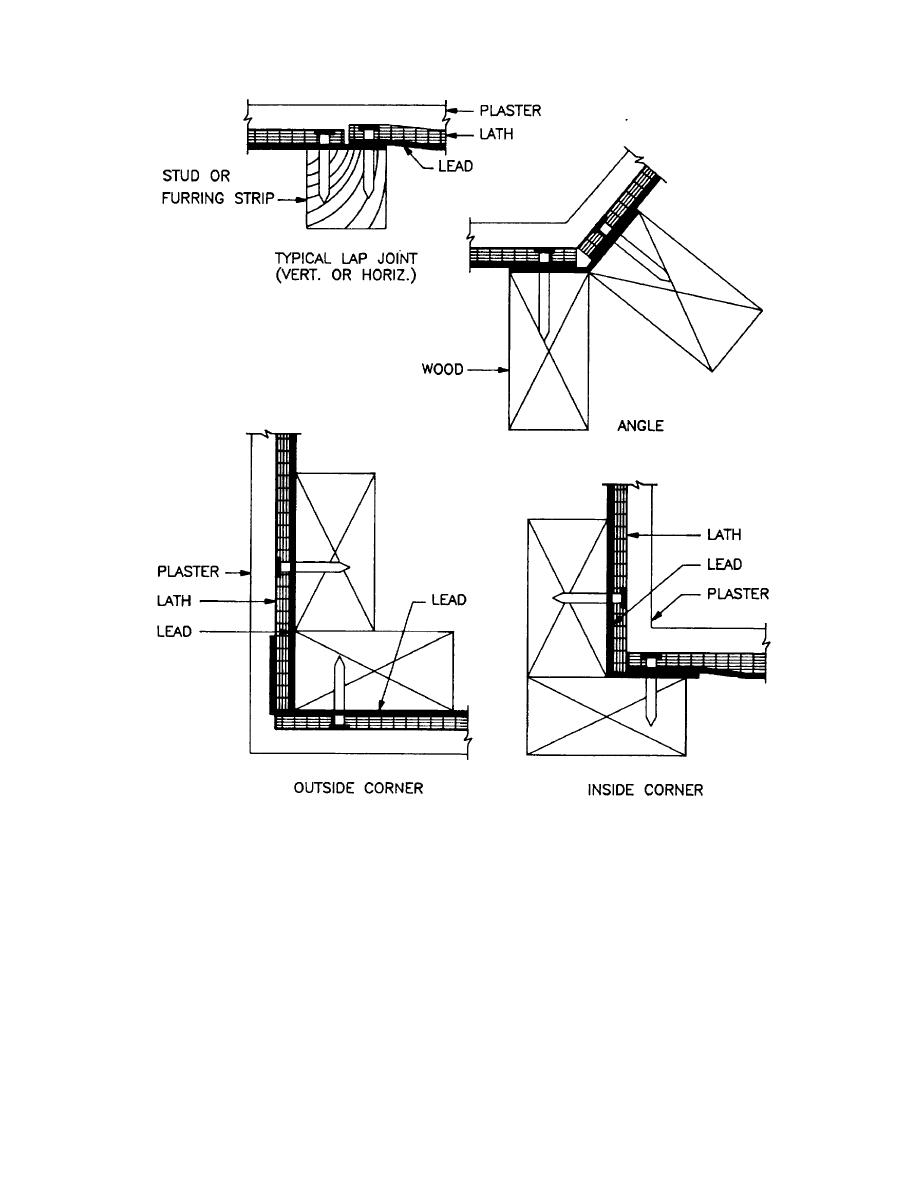

(2) Lead-lined panels will be butt-jointed with all joints placed over supports and with lead linings placed next to

supports. Lead laps at corners and around frames of openings will be made with panels having lead extensions or with

sheet-lead strips not less than the thickness of the lead in the panel.

(3) At intermediate supports, panels are nailed in a uniform pattern at approximately 16 inches on centers by

nails covered with 5/16-inch lead disks and wood putty, or by finishing nails where supports are covered by not less than a

1-1/2-inch wide lead strip. Nailing at joints conforms to one of the following methods.

(a) Joints with lead-lined joint strips. This method is used primarily with unfinished plywood. Sides and

ends of panels will be nailed at approximately 8 inches on centers with wire nails long enough to penetrate the support or

furring members. Joints are covered with a 2-inch wide lead-lined joint strip of the same material as the panel. The joint

strips are secured with nails approximately 8 inches on centers that penetrate into the support and are covered with a lead

disk and wood putty or, with nails that penetrate joint strip and plywood but not the lead-lining of the panel. Where

indicated,quarter-round strips of the same finish as the panels are installed adjacent to joint strips and secured by nailing

with wire nails to joint strips without penetrating the lead.

1-9

Previous Page

Previous Page