TM 5-805-12

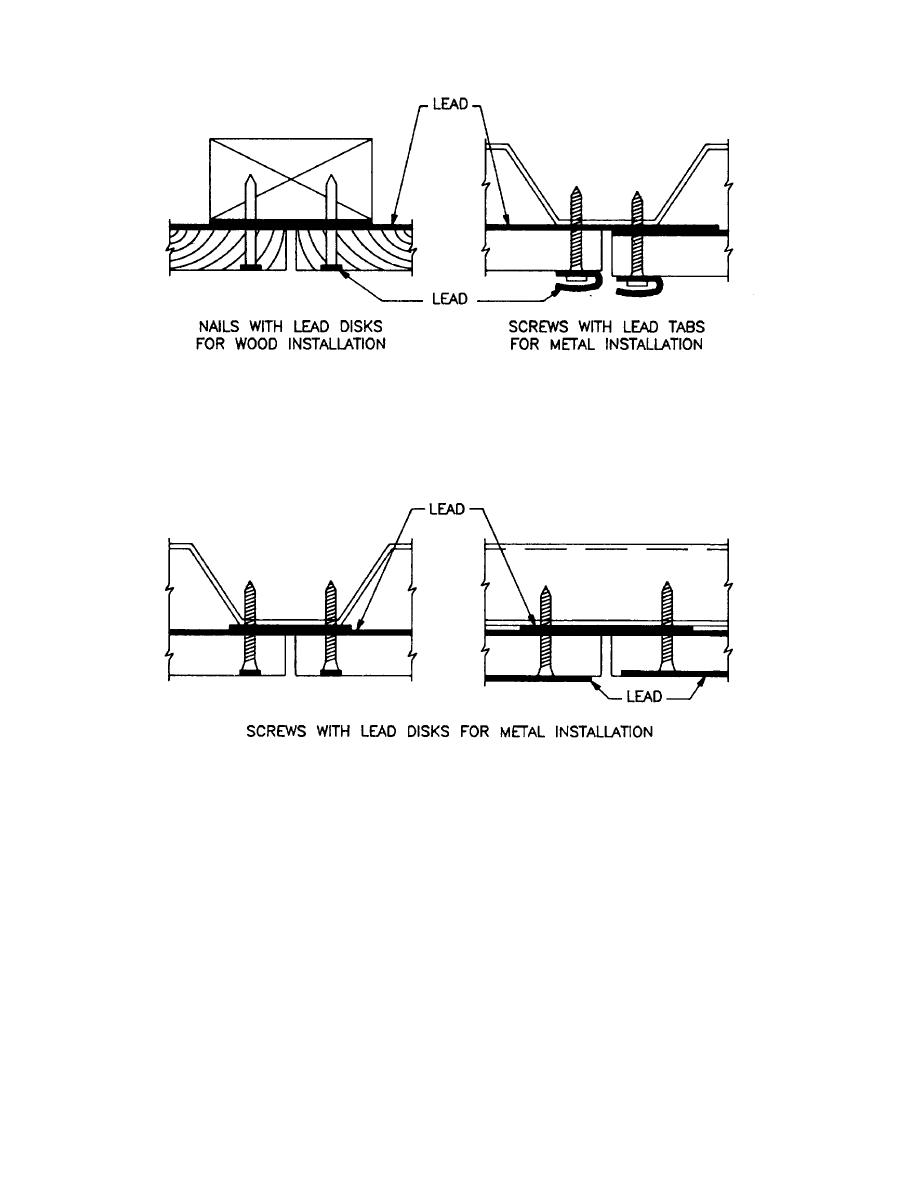

Figure 1. Fastening methods.

b. Lead-lined lath. Lead-lined lath consists of a sheet of unpierced lead laminated to perforated gypsum plaster

lath. For lead sheets up to 8.0 millimeters thick (light lead), the standard lath size is 3/8 inch thick, 16 by 48 inches, with a

single thickness of sheet lead 17 by 49 inches that is laminated so that the lead extends 1 inch beyond one longside and

one shortside of the unit. For lead sheets 8.0 millimeters and over (heavy lead), the standard lath size is 3/8 inch thick, 12

by 48 inches, with single thickness of sheet lead 12 by 48 inches. See figure 3 for jointing details. Supports for heavy

lead-lined lath are 12 inches on centers.

(1) Pilot holes for nails are predrilled or field drilled as necessary to prevent deformation of the nail and

distortion of the lath.

(2) Light lead-lined lath can be installed by one of the following methods:

(a) Lead-lined lath can be applied with long edges at right angles to supports and with lead linings placed

next to the supports. End joints are placed over supports and staggered in alternate courses. Wall joints will not coincide

with ceiling joints. Each sheet will overlap the lead extension on the adjacent sheet, providing an effective lead lap.

(b) Lead-lined lath can be applied with long edges parallel to supports and with lead linings placed next to

supports. Blocking is provided at end joints. Sheet-lead strips not less than the thickness used for the lath and not less

than 1-1/2 inches wide are applied on blocking and on supports where joints occur. The lead strips are secured to

blocking and supports by nailing with wire nails at outer edge of strips.

1-7

Previous Page

Previous Page