TM 5-805-12

Figure 2. Wallboard.

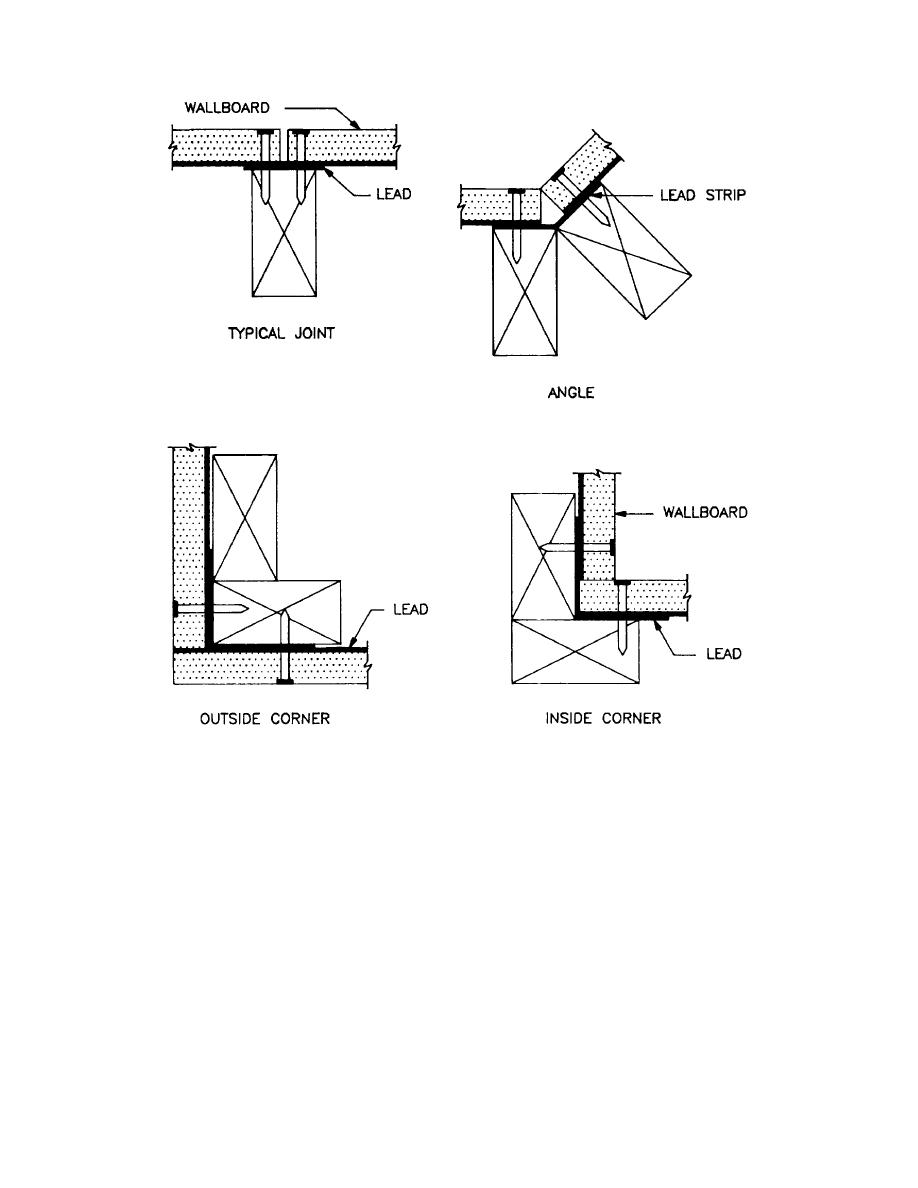

(3) Heavy lead-lined lath is installed at right angles to supports and with lead linings placed next to supports.

Blocking is provided at all joints where there are no supports. Sheet-lead strips not less than the thickness used for the

lath and not less than 1-1/2 inches wide are applied on blocking and supports where joints occur. The lead strips are

secured to blocking and supports by nailing with wire nails at outer edge of strips.

(4) The lath must be close fitted and uniformly secured to supports and must extend into frame openings,

effectively lapping with the lead frames or frame linings. Unless otherwise approved, lath is arranged around openings

such that neither horizontal nor vertical joints occur at corners of openings. External corners are reinforced with corner

beads. Internal corners, except at unrestrained suspended ceilings, are reinforced as required by manufacturer and

installed with nails or tie wire and lead clips. At unrestrained ceilings, squarenosed casing beads are installed at junction

of wall and suspended ceilings.

(5) The lath is uniformly nailed or secured with tie wire to supports at approximately 7 inches on centers.

All penetrations of the lead linings by wire or nails must be effectively covered with lead clips.

c

Lead-lined panels. Lead-lined panels consist of a sheet of unpierced lead laminated to a sheet of fir plywood.

The standard panel size is 3/8 inch thick, 4 feet by 7 feet, unless otherwise indicated. See figure 4 for details.

(1) Pilot holes for nails will be predrilled or field drilled as necessary to prevent deformation of the nail and

distortion of the panel.

1-8

Previous Page

Previous Page