CEMP-E

TI 809-07

NOVEMBER 1998

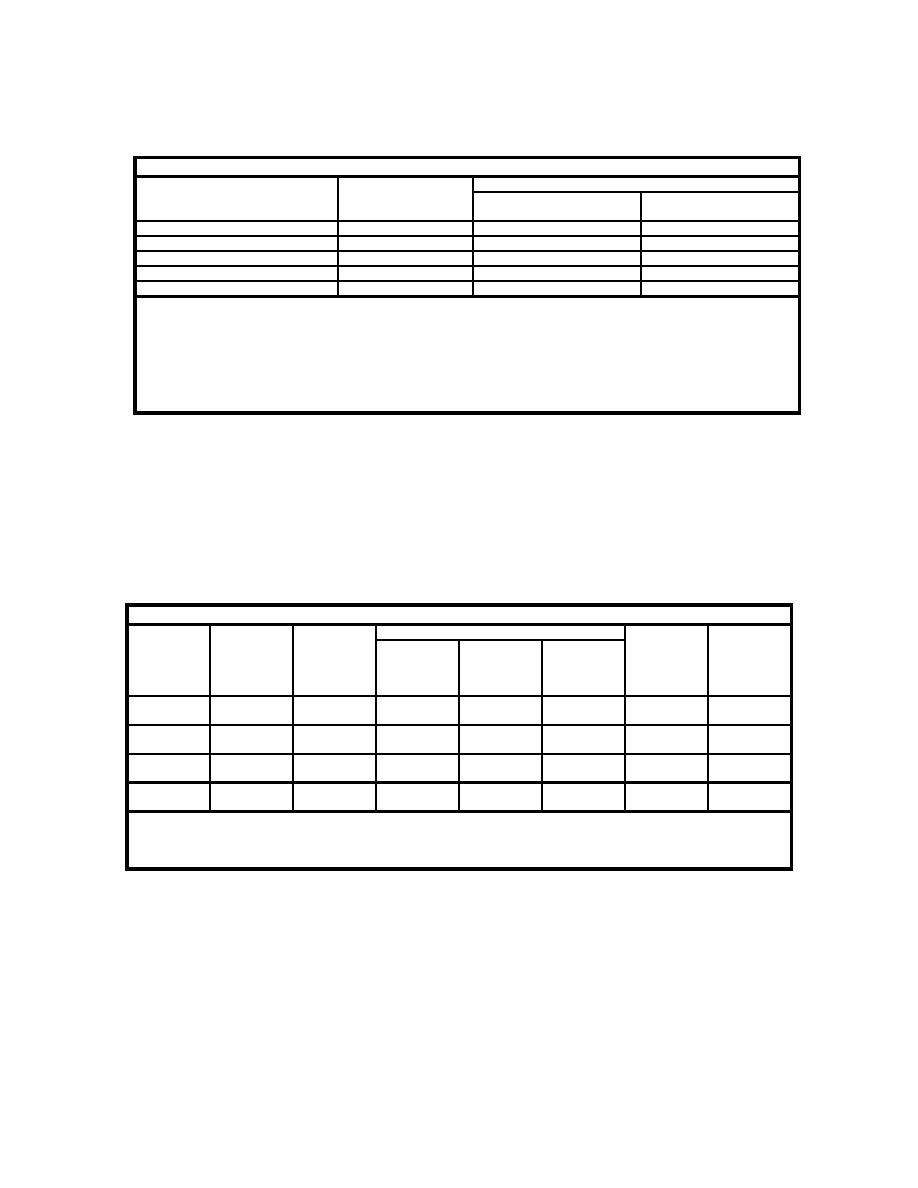

Table 2-5: Suggested Design Loads for Fillet and Flare-Bevel Groove Welds

Weld Size

Design Thickness

Weld Strength

t

Fillet

Flare-Bevel Groove

mm (in)

mm (in)

N/mm (lbs/in)

N/mm (lbs/in)

3.15 mm (0.1240")

4.76 (3/16)

215 (1228)

172 (982)

2.583 (0.1017)

3.97 (5/32)

176 (1007)

141 (806)

1.811 (0.0713)

3.18 (1/8)

124 (706)

99 (565)

1.438 (0.0566)

3.18 (1/8)

98 (560)

78 (448)

1.146 (0.0451)

3.18 (1/8)

78 (447)

63 (358)

Notes:

1. Welds can be positioned in shear or tension.

2. Weld strength for fillet = 0.3 F t, where t = minimum welded material thickness.

y

3. Weld Strength for flare-bevel groove = 0.3 F t/1.25.

y

4. Values shown are for F = 228 MPa (33 ksi). For F = 278 MPa (40 ksi) multiply tabulated values by 1.33. For F =

y

y

y

345 MPa(50 ksi) multiply tabulated values by 1.52.

5. Flare-bevel groove welds occur between the outside radius of one piece and a flat surface of another piece.

d. Anchors. ASTM F 1554 for Anchor Bolts covers straight, bent, headed, and headless

bolts for anchoring the structural support to the foundation. Bolts covered have diameters from

6.35 mm ( in) to 101.6 mm (4 in) and yield strengths of 248, 379, and 724 MPa (36, 55 and 105

ksi).

i) Expansion Anchors or similar devices will be designed as bolted connection between

the anchor and the cold-formed structure. In lieu of specific anchor data the suggested

values in table 2-6 may be used. Designer must assure that the anchors as supplied

meet the design requirements.

Table 2-6: Suggested Capacity for Expansion Anchors in Stone Aggregate Concrete

Anchor

Minimum

Type of

Concrete Strength MPa (psi)

Minimum

Minimum

Diameter

Embedment

Loading

Anchor

Edge

13.8

27.6

41.4

Spacing

Distance

(2000)

(4000)

(6000)

mm (in)

mm (in)

mm (in)

mm (in)

kN (lbs)

kN (lbs)

kN (lbs)

6.35

64

Pullout

1.45 (325)

1.89 (420)

1.87 (420)

64

32

()

(2-1/2)

Shear

1.69 (380)

2.89 (650)

2.89 (650)

(2-1/2)

(1-1/4)

13

70

Pullout

2.96 (665)

4.00 (900)

5.38 (1210)

127

64

()

(2-3/4)

Shear

7.6 (1710)

9.25 (2080)

10.3 (2320)

(5)

(2-1/2)

19

83

Pullout

4.16 (935)

5.65 (1270)

6.0 (1360)

191

95

()

(3-1/4)

Shear

13.6 (3050)

19.0 (4270)

20.0 (4510)

(7-1/2)

(3-3/4)

25

114

Pullout

7.2 (1610)

8.9 (2000)

11.3 (2530)

254

127

(1)

(4-1/2)

Shear

27.9 (6280)

29.9 (6720)

35.4 (7960)

(10)

(5)

Notes:

1. Pullout values listed may be doubled with special inspection.

2. Values may not be increased 1/3 for wind for seismic loads.

3. ICBO uninspected values - Hilti/ICBO report #2156.

ii) Powder driven pins may be used to attach cold-formed members to concrete or

structural steel typical suggested capacities are shown in tables 2-7 and 2-8.

e. Connections and Joints. In Cold-formed steel design the AISI specification is to be used

when the thickness of the thinnest sheet being connected is less than 4.8 mm (3/16"), when the

thickness of the thinnest material is greater than 4.8 mm (3/16") use the AISC specification. AISI

uses only bearing connections, snug tight fit. In cold-formed design washers are typically not

used in cold-formed steel construction. The primary mode of failure is sheet tearing for AISI

designed connections. Two limit states are considered in the design of cold-formed steel

connections: tilting of screw and subsequential tearing of sheet, and tension pull over are

common. Riveted and crimped fasteners are proprietary connections, they are not to be used in

COE designs. Table 2-9 gives some suggested loads per fastener for joist clip angles.

2-13

Previous Page

Previous Page