CEMP-E

TI 809-07

NOVEMBER 1998

5. FASTENERS AND CONNECTIONS

a. Sheet Metal Screws. AISI Specification for the Design of Cold-Formed Steel Structural

Members and accompanying Commentary - Section E4. This section is applicable to screws with

a nominal diameter of 2.03 mm (0.08 in) d 6.35 mm (0.25 in). The nominal diameter is

measured across the threads and will be thread forming or thread cutting. Screws may be used

with or without a self drilling point. Table 2-4 gives some suggested loading values for screw

connections. Pullout values are for attaching facing materials and are not to be used for

connection design.

b Bolts. AISI Specification for the Design of Cold-Formed Steel Structural Members

and accompanying Commentary - Section E3. Bolts are designed for sheets with the thinnest

sheet being less than 4.8 mm (3/16 in). When the thinnest sheet is greater than 4.8 mm (3/16 in)

use the AISC specification. Four design conditions need to be considered:

Longitudinal shearing of the sheet parallel to the through the end of the sheet,

Bearing or piling up behind the bolt,

Tearing through the net section,

Shearing of the bolt.

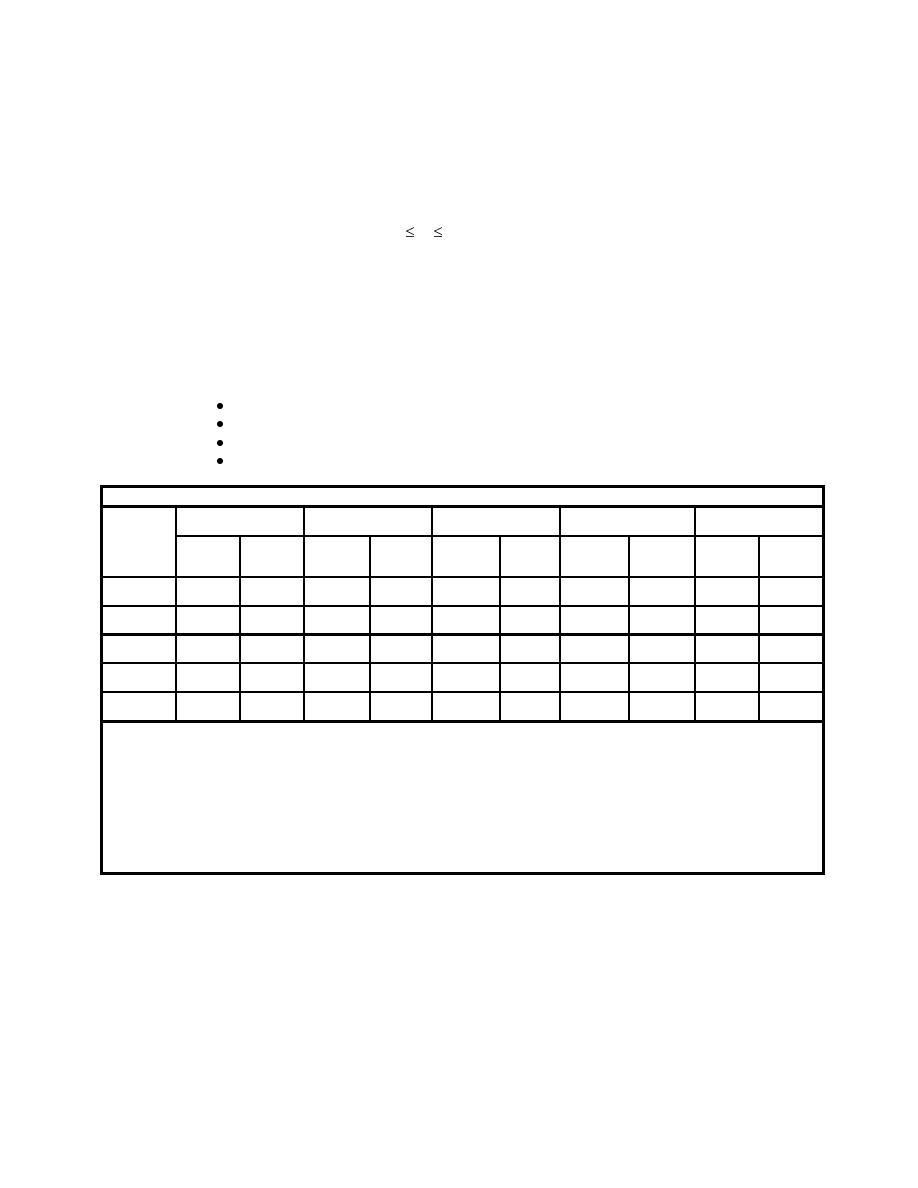

Table 2-4: Suggested Capacities for Screw Connectors in kN (lbs)

Steel

No. -14

No. 12-14

No. 10-14

No. 8-14

No. 6

Nominal /

Design

Shear or

Pullout

Shear or

Pullout

Shear or

Pullout

Shear or

Pullout

Shear or

Pullout

Thickness

Bearing

Bearing

Bearing

Bearing

Bearing

mm (in)

2.583

2.60

1.57

2.00

1.44

1.45

1.40

NA

1.35

NA

NA

(0.1017)

(585)

(352)

(450)

(324)

(327)

(314)

(303)

1.811

2.27

1.08

1.83

0.96

1.27

0.91

NA

0.89

NA

NA

(0.0713)

(511)

(242)

(412)

(215)

(286)

(205)

(200)

1.438

1.89

0.71

1.68

0.68

1.16

0.67

1.05

0.63

NA

0.59

(0.0566)

(426)

(159)

(377)

(153)

(261)

(151)

(236)

(142)

(132)

1.146

1.34

0.45

1.23

0.45

1.17

0.44

1.10

0.42

0.84

0.37

(0.0451)

(301)

(101)

(276)

(101)

(263)

(98)

(248)

(94)

(188)

(83)

0.879

0.69

0.32

0.64

0.31

0.63

0.31

0.62

0.30

0.59

0.24

(0.0346)

(154)

(71)

(143)

(70)

(141)

(69)

(140)

(68)

(133)

(53)

Notes:

1. NA: not applicable, two thicknesses of this metal gage cannot be connected by this size screw.

2. Screw capacity is based on a minimum connected strength of F = 228 MPa (33 ksi). The ratio of the material ultimate tensile

y

strength to yield strength should be equal to or greater than 1.15.

3. Screw a spacing and edge distance shall not be less than 1.5D or P/0.6F , where D is the screw shank diameter and P is the

yt

shear load.

4. Screw capacities are based on average test results divided by a safety factor of 3.0. Test data is available from Buildex Division

of ITW, Inc Itasca, Illinios; test #845, uninspected values.

5. For steels having yields other than 228 MPa (33 ksi), use the following formula:

Table Value(Actual yield strength)/(228 or 33 in consistent units) = New value

c. Welds. AISI Specification for the Design of Cold-Formed Steel Structural Members and

accompanying Commentary - Section E2. The maximum thickness for the use of the AISI

specification when welding sheets together is 4.6 mm (0.18 in) for the thinnest sheet. When

welding thicker sheets use the AISC specification. Resistant welded sheets are limited to 3.2 mm

(0.125 in) or less for the thinnest sheet. Table 2-5 gives some suggested values for fillet and

flare-groove welds.

2-12

Previous Page

Previous Page