UFC 3-240-13FN

25 May 2005

4-4.5

Algae Control. Algae can be controlled by two techniques: chemical

methods and physical methods. Since algae require sunlight to survive and grow,

covering the upper hot water decks of cooling towers with plywood can often control

algae deposits. Chemical methods consist of using oxidizing and non-oxidizing biocides,

which can control algae to various degrees (see Tables 4-6 and 4-7). The effectiveness

of oxidizers is considered only fair while that of several non-oxidizers is in the range of

very good to excellent. One of the more effective biocides for algae is terbutylazine, a

triazine product (see Table 4-7).

4-4.6

Bacterial Control. Accepted industry practice for bacterial control is the

use of oxidizing and non-oxidizing biocides that are specific for the type of bacteria. The

most cost-effective microbiocide programs for medium and large cooling towers use an

oxidizer as a primary biocide and one or more non-oxidizers selectively as a secondary

biocide (see Tables 4-6 and 4-7). Smaller cooling systems often use one or more non-

oxidizing biocides, although dry oxidizing biocides are also used commonly. The most

overlooked aspect of bacterial control is maintaining a system kept clean of deposits

and SS (i.e., dirt, silt, sand, corrosion products) through the use of filters and periodic

wash-down procedures. Clean systems reduce the demand for chemical and

microbiological control. Table 4-8 shows accepted industry guidelines for a bacterial

control program with the use of a test kit.

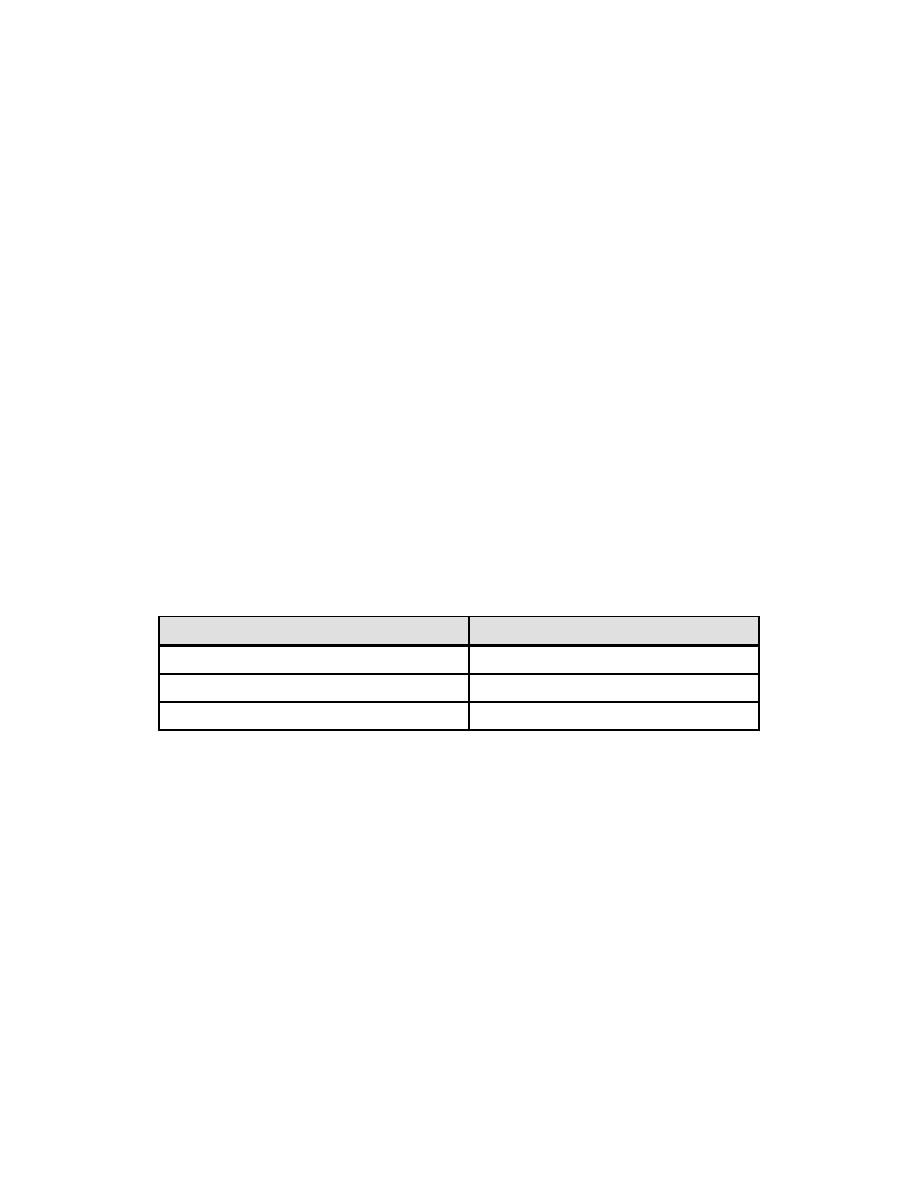

Table 4-8. Guidelines for Bacterial Control in Cooling Towers

Bacterium Type

Colony-Forming Units/ml

< 104

Total aerobic bacteria

Sulfate-reducing bacteria

Undetectable

< 106 Undetectectable

Surface microbiological

4-4.6.1

Bacterial Control with Oxidizing Biocides. Bacterial control with

oxidizing biocides can be accomplished by either continuous feed or slug feed of the

oxidant. A continuous-feed process typically maintains 0.1 to 0.3 ppm of free halogen in

the return water to the cooling tower. A typical slug-feed process adds treatment

chemicals periodically to give 0.5 to 1.0 ppm of free halogen in the return water to the

cooling tower for a period of 2 to 4 hours, 3 times per week. Halogen refers to the group

of elements including chlorine and bromine. "Free" halogen refers to the measured

residual of halogen available for disinfection. Stabilized Halogen technology is generally

controlled on a total halogen residual. For continous feed, control at 0.5 to 1 ppm total,

and for slug feed control at 2.4 ppm for a period 2-4 hours, 3 times per week.

4-4.6.2

Bacterial Control with Non-Oxidizing Biocides. Bacterial control with

non-oxidizing biocides uses one or more biocides as shown in Table 4-7. Usually

different non-oxidizers are added on an alternating schedule; they are slug-fed every

other week for optimum effectiveness. Each time you use a non-oxidizing biocide, it is

123

Previous Page

Previous Page