UFC 3-410-04N

25 October 2004

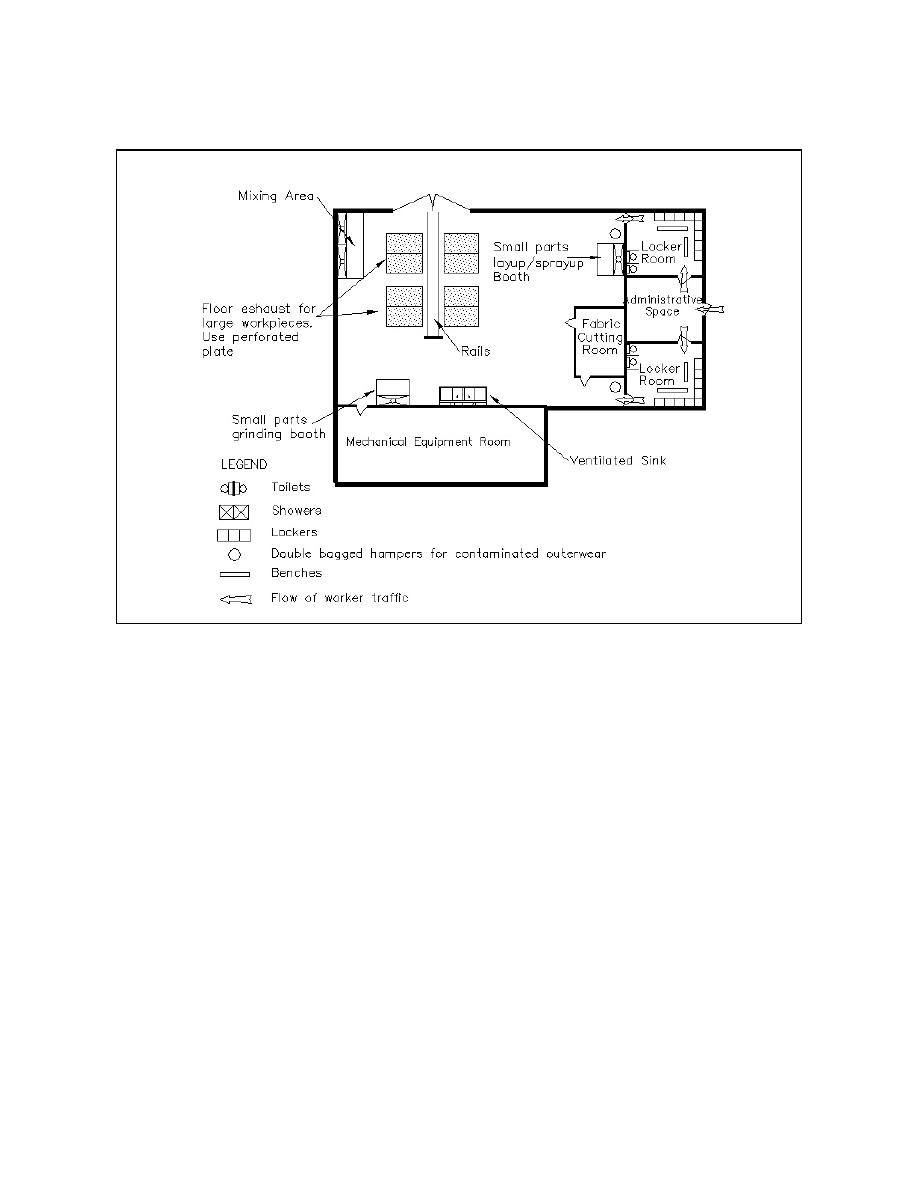

Figure 5-1. Floor plan for FRP facility.

5-4

DESIGN CRITERIA. Design the facility using general technical

requirements in Chapter 2 of this UFC and the specific requirements in this Chapter.

5-4.1

Exhaust Air System. Provide an exhaust system that captures

contaminated air generated during FRP fabrication and repair operations. Refer to

Chapter 2 of this UFC; UFC 3-600-01; NFPA 33, Standard Spray Application Using

Flammable and Combustible Materials; NFPA 68, Guide for Venting Deflagrations;

NFPA 91,Standard for Exhaust Systems for Air Conveying of Materials; NFPA 654, and

the specific requirements of this Chapter.

5-4.2

Hood Design. The sizes and shapes of work pieces in FRP fabrication

and repair facilities vary. Design separate hoods for processes producing only

particulate and only vapor, and both particulate and vapor. Consider a molding system

that completely encloses the work piece if the facility repeatedly manufactures the same

work piece. Design exhaust hoods to enclose all processes to the greatest possible

extent without inhibiting operations. Baffle all exhaust hoods to reduce cross drafts and

improve hood efficiency. Table 5-1 summarizes recommended exhaust hoods, capture

velocities, and air pollution control devices for each operation.

5-2

Previous Page

Previous Page