UFC 3-410-04N

25 October 2004

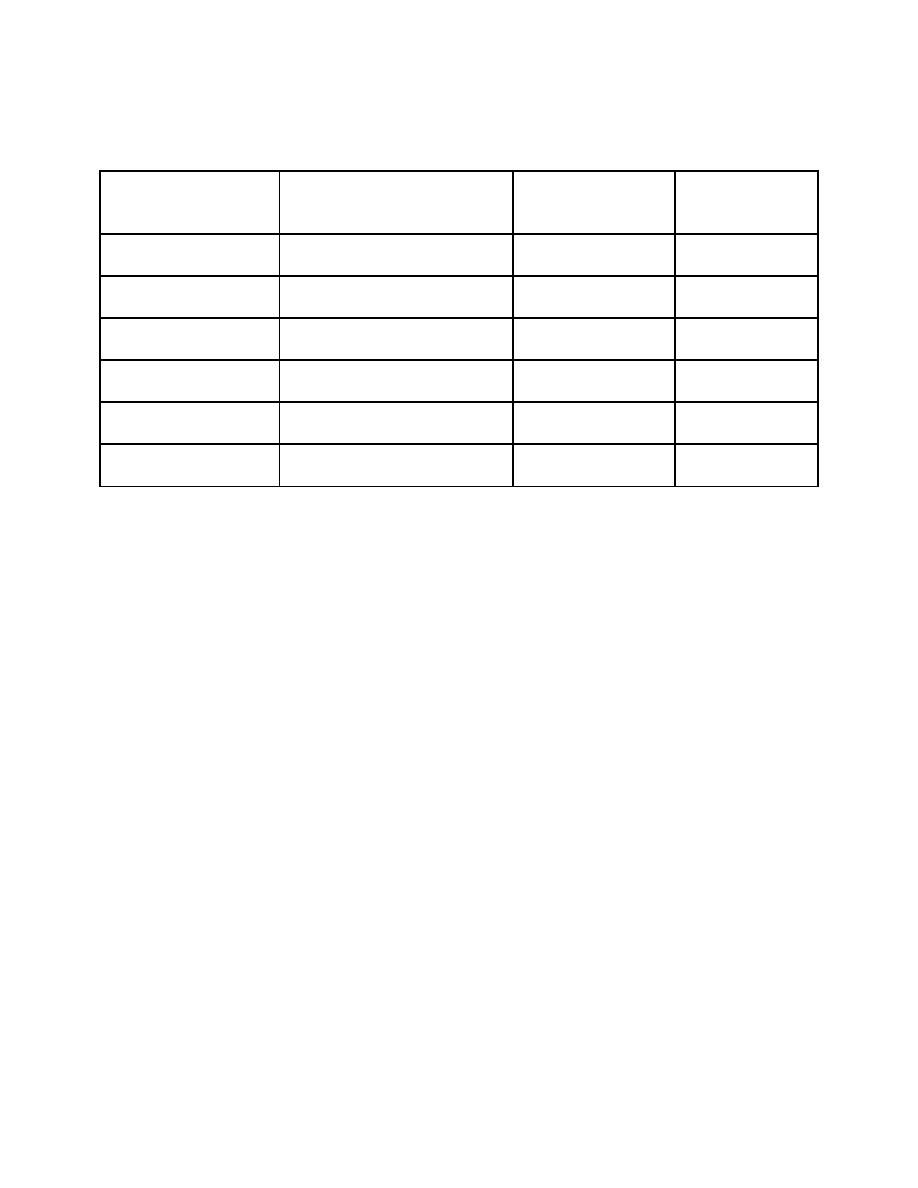

Table 5-1. Recommended Hood, Capture Velocity, and Air Pollution Device

Air Cleaning

Recommended

Operation (expected

Device

Capture Velocity

contaminant)

(see notes)

(m/s (fpm))

Hood Type

Chemical Mixing

Workbench (Figure 5-2)

0.51 m/s (100)

1

(vapors)

Lay up (Vapors)

Workbench/Floor Exhaust

0.51 m/s (100)

1

(Figure 5-3)

Spray up (Vapors)

Spray up Booth

0.51 m/s (100)

1

(Figure 5-4)

Grind,Cut,Saw

Workbench/Floor Exhaust

0.76 m/s (150)

2

(Particulate)

(Figure 5-3)

Cleanup (Vapors)

Ventilated Sink

0.51 m/s (100)

3 or 1

(Figure 5-5)

Hand Tools

LVHV Vacuum System

Not

2

(Particulate)

applicable

NOTES:

(1) Determined by the local air pollution regulatory agency,

(2) fabric collector, and

(3) substitute an aqueous emulsion cleaner for acetone.

5-4.2.1

Plenum Velocity. Design the plenum velocity at least one-half, but no

greater than, the velocity through the perforated plate or layered prefilter to create an

even airflow over the hood face. Design the hood-to-duct transition with an included

angle of no more than 90 degrees.

5-4.2.2

Hood Length. Specify that the length of the hood served by each

exhaust plenum will not exceed 2.44 m (8 ft). For example, hoods between 2.44 and

4.88 m (8 and 16 ft) in length will have two exhaust takeoffs. Provide cleanout doors in

the plenum to allow removal of accumulated particulate.

5-4.2.3

Portable Hand Tools. Use portable hand tools with LVHV vacuum

systems for sawing, cutting, and grinding on all work pieces. Ensure that the tools, with

their vacuum hoses, are properly sized for the work piece internal angles and curvature.

LVHV systems are described in paragraph 5-4.7.

5-3

Previous Page

Previous Page