UFC 3-410-04N

25 October 2004

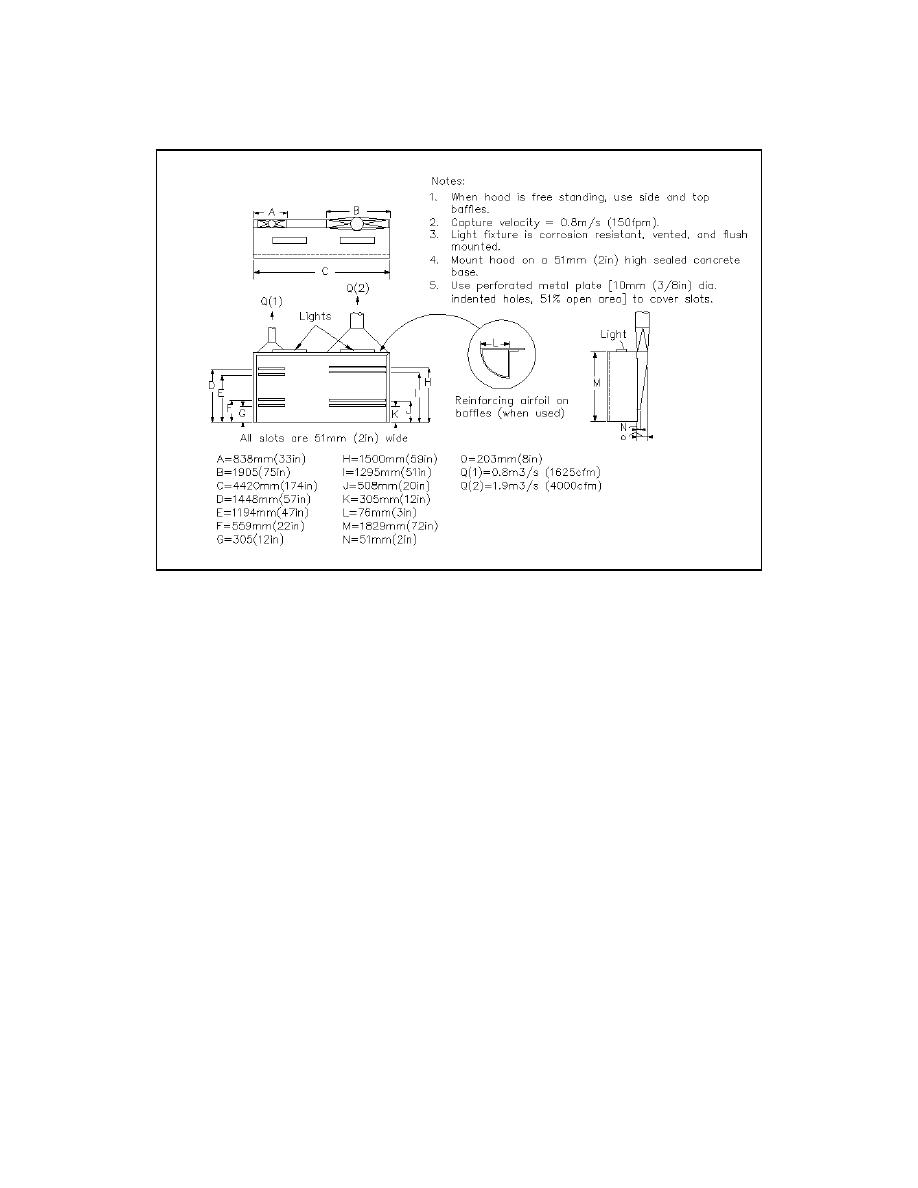

Figure 4-7. MK-48 afterbody teardown hood.

4-3.2.2

dismantle and inspect the fuel tank and the engine section. They then load components

of the fuel tank and the engine section into the parts washer. Design a backdraft

exhaust hood as illustrated in Figure 4-8 to control contaminants generated by these

workbench operations. Specify the following criteria for workbench hoods:

a. A 1850- x 600-mm (72- by 24-in) stainless steel workbench top to

support the whole exhaust hood. See Figure 4-8 for dimensions of the

hoods.

b. A 76-mm (3-in) airfoil rotated inward to prevent turbulence and

backflow.

c. Lighting that is vented and flush mounted in the top of the exhaust

hood.

4-3.2.3

MK-48 Parts Washer Hood. Design or modify the parts washers as

shown on Figure 4-9. Specify the following criteria for the parts washers:

a.

Fabricate a new enclosure to mount on top of the parts washer.

b. Relocate the cover with a pneumatic plunger and a fusible link

assembly.

4-7

Previous Page

Previous Page