UFC 3-410-04N

25 October 2004

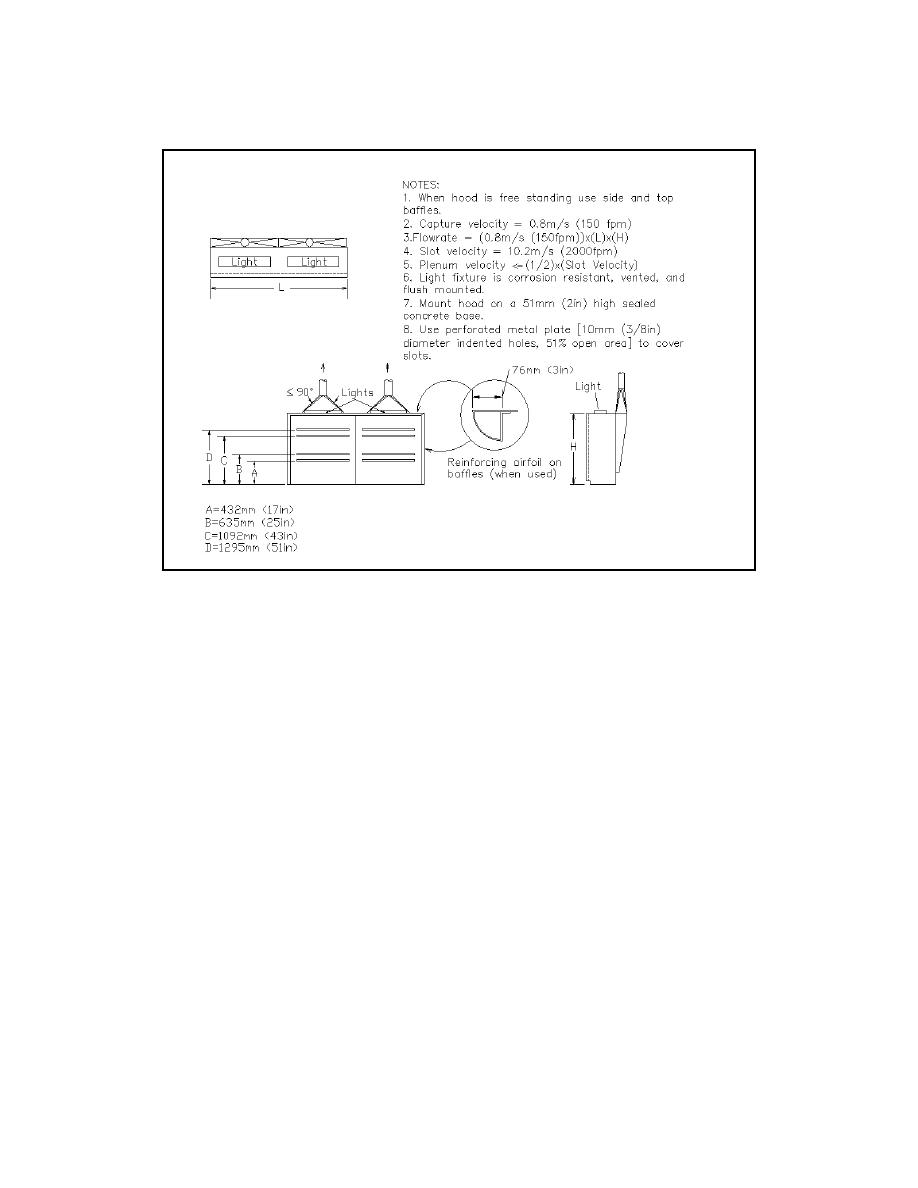

Figure 4-3. MK-46 standup backdraft hood.

d. Hood transitions (takeoffs) with an included angle no greater than 90

degrees. Length of the hood, served by an exhaust plenum, is not to

exceed 2.44 m (8 ft). For example, hoods between 2.44 and 4.88 m (8

and 16 ft) in length have two exhaust takeoffs.

e. Baffles to control airflow from the sides and top of the hood bank as

shown on Figure 4-3.

4-3.1.2

fuel and engine sections onto two different ventilated workbenches. They remove the

stabilizing baffles in the fuel section, inspect, and wipe them clean before loading the

baffles into the parts washer. Personnel also dismantle the engine section to inspect

the engine, fuel pump, and seawater pump before loading them into the parts washer.

Design a backdraft exhaust hood, as illustrated in Figure 4-4, to control contaminants

generated by these workbench operations.

4-3.1.3

MK-46 Parts Washer Hood. Design parts washer as shown on Figure 4-

5 to clean off oils and excess Otto Fuel II from torpedo components. The parts washer

cover must automatically close in case of fire in accordance with NFPA 34, Standard for

Dipping and Coating Processes Using Flammable or Combustible Liquids. Design the

parts washer large enough to completely enclose the work piece. Design the parts

washer deep enough to allow a minimum clearance of 153 mm (6 in) between the liquid

level and the exhaust slot when the tank is full of parts. Position the parts washer next

to the workbenches to shorten the work path and optimize ventilation control.

4-3

Previous Page

Previous Page