UFC 3-410-04N

25 October 2004

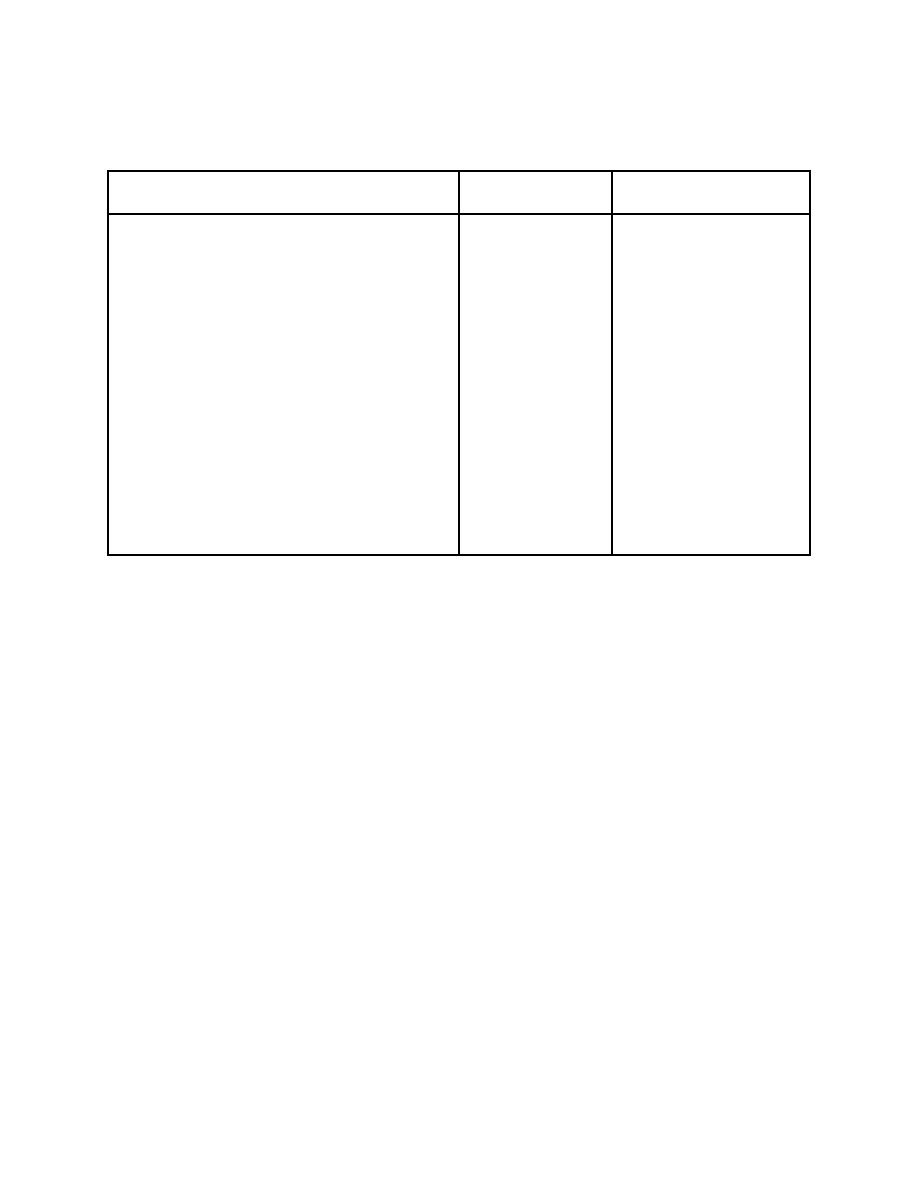

TABLE 3-1. Minimum Volumes and Vacuum Hose Size for Asbestos Operations

Flow rate

Hose Size

m3/s (cfm)

Hand Tool

mm (in.)

38 (1.5)

0.06 (125)

Pneumatic chisel

38 (1.5)

0.07 (150)

Radial wheel grinder

38 (1.5)

0.07 (150)

Cone wheel grinder, 2 inch

51 (2.0)

0.09 (200)

Cup stone grinder, 4 inch

51 (2.0)

0.12 (250)

Cup type brush, 6 inch

38 (1.5)

0.08 (175)

Radial wire brush, 6 inch

38 (1.5)

0.06 (125)

Hand wire brush, 3 x 7 inches

38 (1.5)

0.08 (175)

Rip out knife

38 (1.5)

0.07 (150)

Rip out cast cutter

38 (1.5)

0.07 (150)

Saber saw

38 (1.5)

0.07 (150)

Saw abrasive, 3 inch

51 (2.0)

0.09 (200)

General vacuum

Adapted from: Hoffman Air and Filtration Systems, "Design of Industrial Vacuum Cleaning Systems and

High Velocity, Low Volume Dust Control."

3-5.7.6

Design the air volume for no less than two parts of air to one part of

asbestos to be captured by weight.

3-5.7.7

Design the vacuum hose length less than 7.6 m (25 ft). Locate inlet

valves 9 to 10.7 meters (30 to 35 feet) apart when a 7.6-m (25-ft) length of hose is used.

Locate tool vacuum hose connection on the ends of the workbench underneath the

stands. Size the hose based on: (1) air volume per hose, (2) number of hoses to be

used simultaneously, and (3) air velocity required to convey the material to the

separators.

3-5.7.8

Use single-ply, lightweight thermoplastic or polyvinyl chloride (PVC)

flexible hose, but limit the usage whenever possible.

3-5.7.9

Use a multistage centrifugal blower for the vacuum system. Size the

blower for: (1) total system pressure loss associated with the total number of hoses to

be used simultaneously, and (2) maximum exhaust flow rate entering the inlet of the

blower.

3-5.7.10

Feed the blower directly into the bag house used by the industrial exhaust

system (see Figure 3-5) to minimize the number of asbestos collection points.

3-6

Previous Page

Previous Page