UFC 3-410-04N

25 October 2004

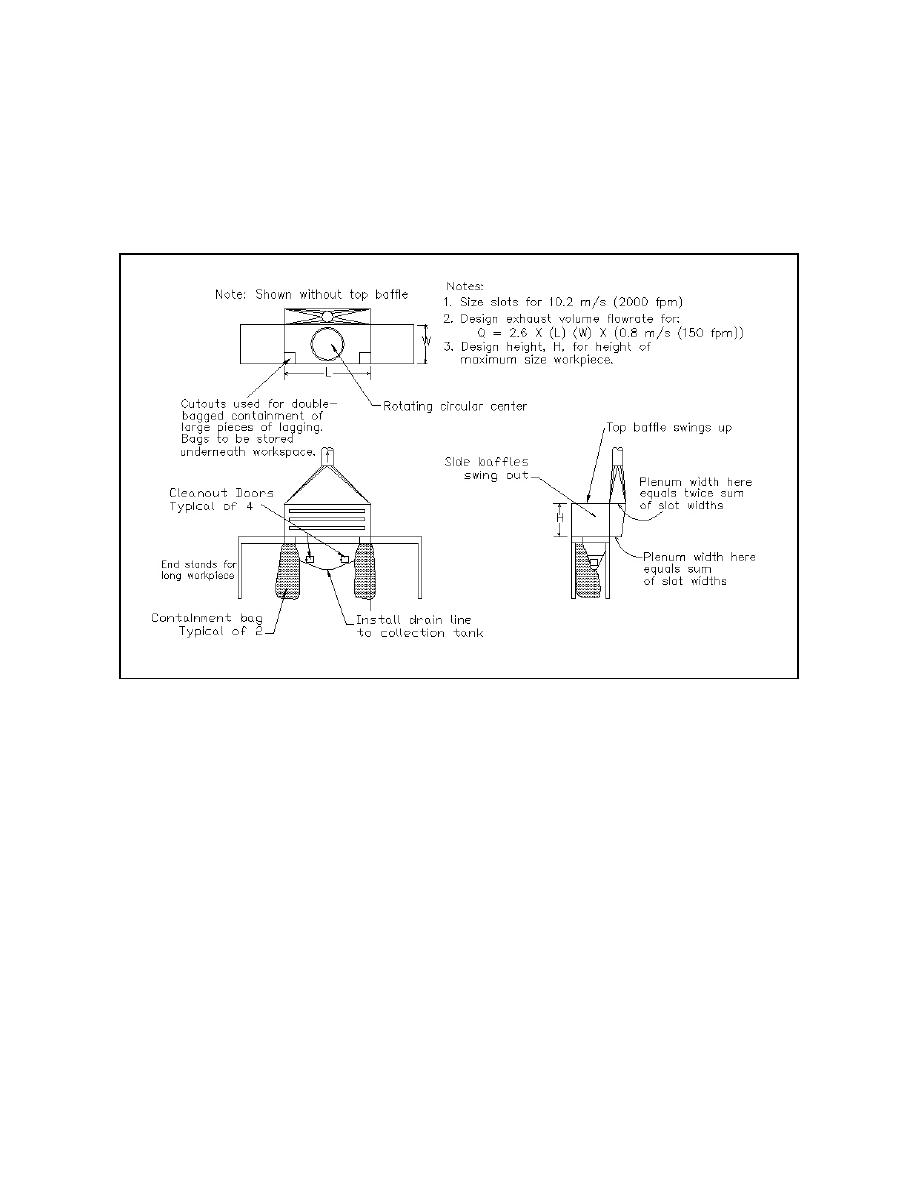

corners of the workbench to place large pieces of lagging in double

bagged containment.

b.

The top baffle swings up to allow access to overhead cranes.

Figure 3-2. Exhaust hood for high profile work pieces.

3-5.1.2

Typical Hood Design for Low Profile Work pieces. Figure 3-3 shows a

hood design consisting of a workbench with a grating strong enough to support the

heaviest expected work piece. This is a downdraft hood that draws small pieces of

lagging through the grating. The perforated plate below the grating creates even airflow

over the grating. This design is best for low profile work pieces such as piping. Design

each hood with stands and swinging baffles on each end to accommodate long work

pieces (e.g., pipes).

3-5.3

velocity of 25.4 m/s (5,000 fpm). The high velocity is necessary because the practice of

wetting the fibers makes them heavier and more difficult to transport. See paragraph 2-

4.1 for general duct considerations.

3-3

Previous Page

Previous Page