CEMP-E

TI 809-07

NOVEMBER 1998

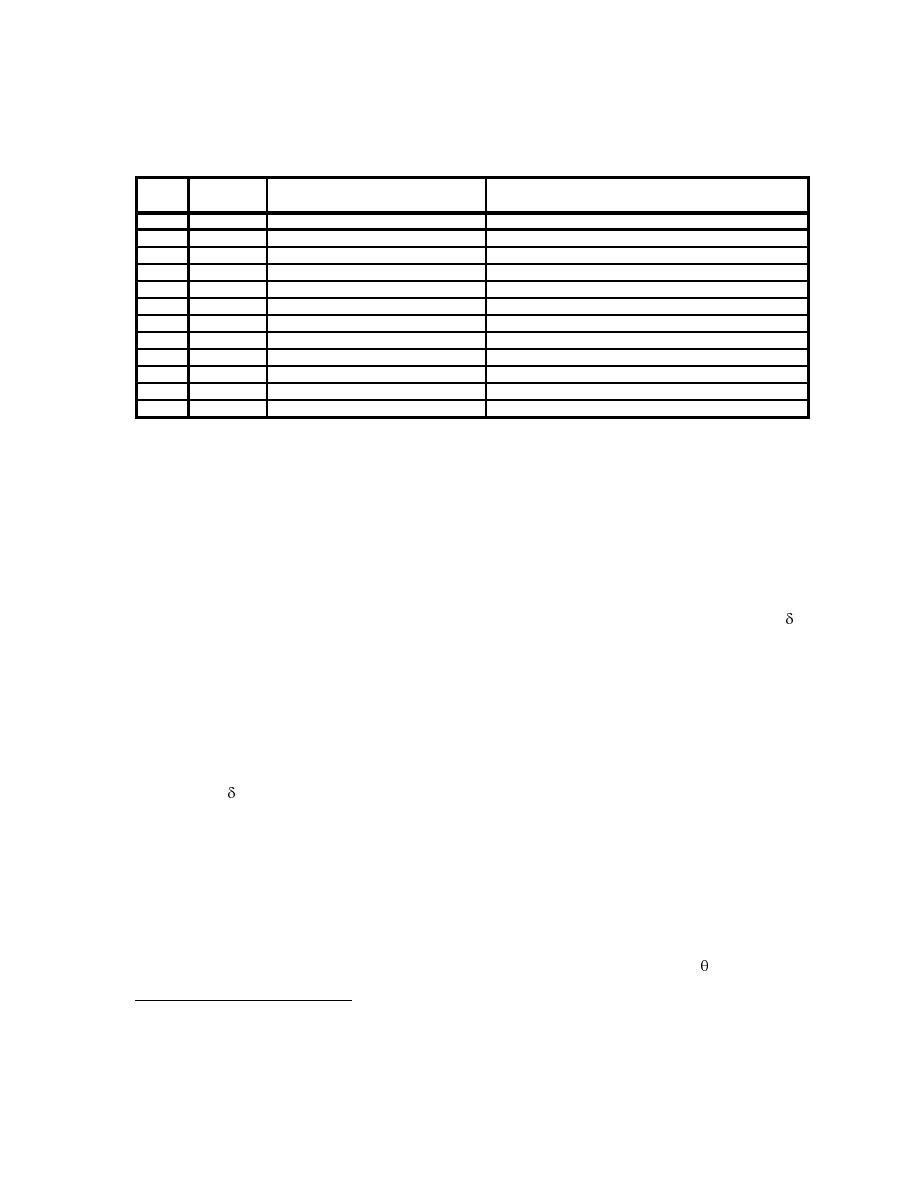

Table F-2. Cold-Formed Steel Shear Panel Instrumentation.

Channel Sensor

Measurement, Direction,

#

Type

Location and Symbol

Purpose

1

Load cell

Force Horizontal, FH

Horizontal actuator load measurement

2

LVDT

Deflection Horizontal, DH

Horizontal deflection, shear panel deformation

3

Load cell

Force Vertical South, FVS

Manual vertical load control (25k total load w/#5)

4

LVDT

Deflection Vertical South, DVS

Stroke (tied to #6)

5

Load cell

Force Vertical North, FVN

Load (summed with #3, for 25k total load)

6

LVDT

Deflection Vertical North, DVN

Controlled by #4 stroke feedback

7

LVDT

Defl Horiz Bot Track, DHBT

To ensure no slippage

8

LVDT

Defl Vert South Bot Track, DVSBT

To ensure no uplift

9

LVDT

Defl Vert North Bot Track, DVNBT

To ensure no uplift

10 LRDG* (20")

Defl Horiz Top Track, DHTT

Check for shear panel deformation - same as #2

11

LRDG (10")

Defl Vert South Top Track, DVSTT Vertical panel/column deformation & rotation check

12

LRDG (10")

Defl Vert North Top Track, DVNTT Vertical panel/column deformation & rotation check

Note: * Linear Resistance Deflection Gauge, often called a Yo-Yo Gauge.

F6. TEST REQUIREMENTS. For each shear panel qualified, three specimens shall be fabricated

and tested. This assumes only minor variation in panel performance for a given shear panel. If large

variations occur more than three specimens shall be tested and a statistical evaluation of panel

performance may be required. For panels with minor variation, one specimen shall be tested

monotonically and two shall be tested cyclically as defined below. All tests, both monotonic and

cyclic shall use stroke control, loading the panels laterally at a constant displacement per minute.

The vertical load shall be held constant and the top beam shall be held horizontal throughout each

test as described in Paragraph F4, Test Configuration. Both monotonic and cyclic tests shall be

conducted up to deflections that cause ultimate failure of the shear panels, or reach the limits of the

test equipment, but shall not be less than 10 times the lateral yield displacement of the test panel, y.

These are very large deflections, well beyond acceptable drift limits, but are needed to ensure that

brittle failures (sudden loss of lateral or vertical load carrying capacity) do not occur near the useful

deflection range of the panel.

a. Monotonic Test Protocol. A single specimen of each shear panel shall be loaded in one

direction (monotonic) at a constant stroke rate that is slow enough to allow careful observation of

1

panel performance and failure progression . These observations shall include documentation of

panel behavior through a log of observations with respect to displacement and photographs. Load

versus deflection (TSF versus DH) shall be plotted to determine the measured lateral yield

displacement y. This value shall be used in defining the cyclic test protocol.

b. Cyclic Test Protocol. A minimum of two specimens of each panel configuration shall be

loaded cyclically at a constant stroke rate that is slow enough to allow careful observation of panel

2

performance and failure progression . These observations shall include documentation of panel

behavior through a log of observations with respect to displacement and photographs. Load versus

deflection (TSF versus DH) shall be plotted to create load/deflection hysteretic envelopes. The cyclic

load protocol follows a standard method, so that test results may be compared with cyclic test results

3

of other systems. The protocol defined here is similar to SAC2 guidelines that have been modified to

4

scale to the lateral yield deflection as described in ATC-24 . The SAC recommended loading

histories call for loading with a deformation parameter based on interstory drift angle, defined as

1

Monotonic tests conducted at USACERL used a stroke rate of 0.5 inches per minute.

2

Cyclic tests conducted at USACERL used a stroke rate of 3 and 6 inches per minute. The faster stroke rate was used for

panels tested cyclically beyond 10 inches (20 inches peak to peak).

3

SAC Testing Programs and Loading Histories, unpublished guidance, 1997.

4

Applied Technical Council (ATC) 24, Guidelines for Cyclic Seismic Testing of Components of Steel Structures, 1992.

F-3

Previous Page

Previous Page