CEMP-E

TI 809-07

30 November 1998

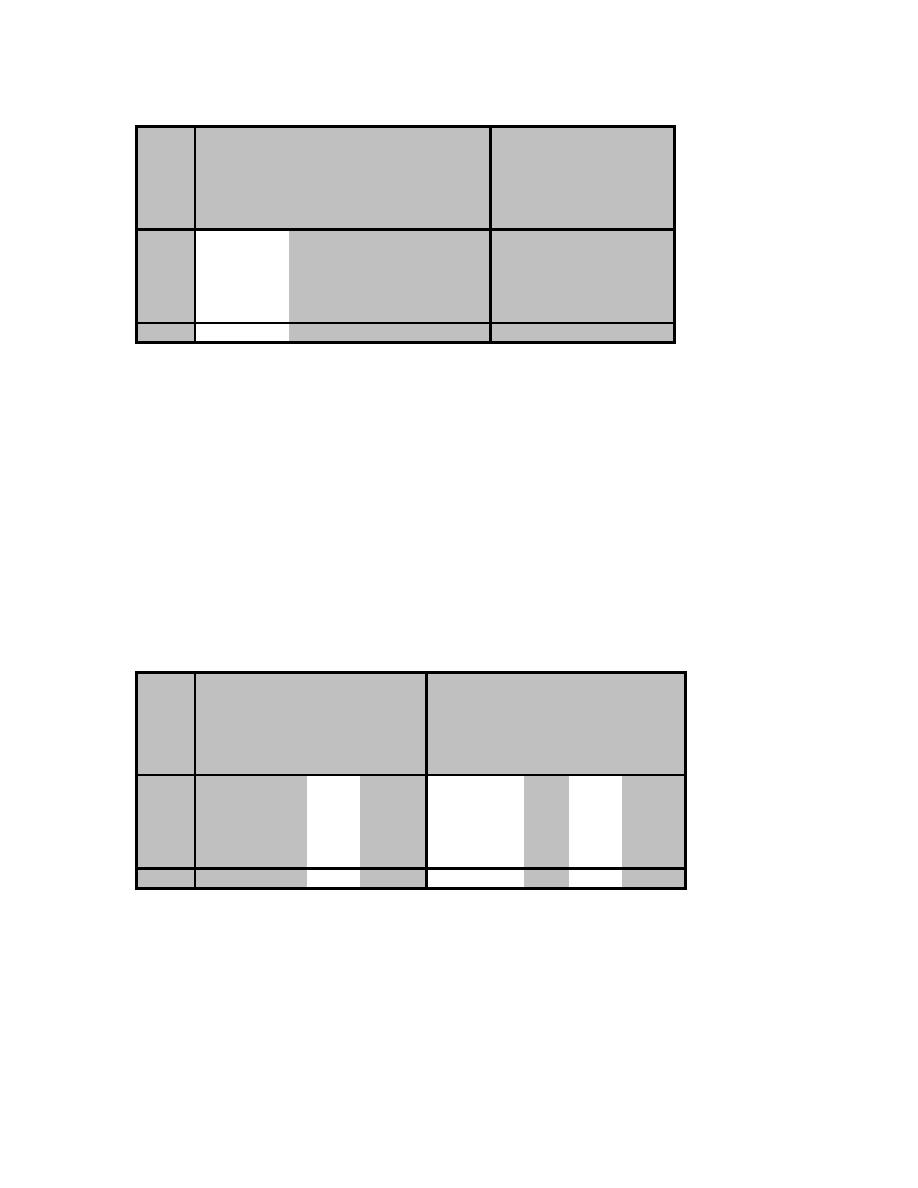

Table D-15. Shear Panel Anchor Angle and Plate Design (continued).

Tensile

Tensile

Angle

Angle

Angle

Distance from Anchor Bolts to:

Column Bolt Nut Crit Bending

Force

Force/

Horiz Weld Vert Weld Tot Weld

Face

Width

Plane

Avail/angle

Angle

Strength

Strength

Strength

dc

db

PM

Pvymax/2+PM

PT

PG

PA

W

(in)

(in)

(in)

(kips)

(kips)

(kips)

(kips)

(kips)

3rd Floor

2.5

1.44

1.16

11.42

17.08

9.69

17.76

27.45

3rd Floor*

2.5

1.44

1.16

14.01

21.34

12.10

11.09

23.19

2nd Floor

2.5

1.63

1.06

17.63

34.66

17.48

16.02

33.50

1st Floor

2.6

1.81

1.09

25.09

47.56

24.48

22.44

46.91

1st Floor*

2.5

1.81

0.97

24.22

45.46

24.48

22.44

46.91

1st Floor

3.5

1.81

1.59

31.90

49.55

39.15

53.83

92.98

Table D-16 presents the anchor (or column) moment capacity as defined by Equation 3-30. Much of

this capacity is used to resist the maximum estimated applied moment from the eccentric loading of

the diagonal strap (PsymaxLs). The uplift capacity per angle that remains to resist column bending, Pcb

should be greater than zero. Table D-16 shows that the panels in Rows 3 and 4 have values slightly

below zero. The panel in Row 3 shall be redesigned as stated earlier and the panel in Row 5 is

selected for the 1st Floor as stated earlier.

c. Shear Panel Anchor Bolt Design. Finally the anchor bolts that fasten the shear panels to

the reinforced concrete beam or slabs are designed. The same detail is used at both the top and

bottom of the columns. The anchor bolts are sized based on the bolt shear strength, Pv, tensile

strength, Pt and cone failure strength, Pc. Table D-16 and Figures D-4 through D-9 show that two

ASTM A-325 anchor bolts are cast into the concrete on both sides of the columns at each anchor, for

a total of four bolts per anchor, nAB. The anchor bolts would be positioned with a template before the

concrete is cast. Alternatively, the same bolts that anchor the top of one panel could extend through

the concrete to anchor the bottom of the panel above.

Table D-16. Anchor Moment and Anchor Bolt Shear Design.

Column

Strap

Moment

Angle

Anchor Applied Bolt Nom Bolt Shear

Moment Max Yield

Arm of

Uplift for

# Anchor

Bolt

Shear/

Shear

Design

Capacity Strength Dia Strap Col Bending Bolts/col

Dia

Bolt

Strength

Strength

Mc

Psymax

Ls

Pcb

nAB

dAB

PhAB

Fv

Pv

(k-in)

(kips)

(in)

(kips)

(in)

(in)

(kips)

(ksi)

(kips)

3rd Floor

55.69

19.72

1.60

4.95

4

3/4

4.00

60

19.88

3rd Floor*

68.31

25.24

2.00

3.66

4

3/4

5.12

60

19.88

2nd Floor

121.21

59.16

2.10

-0.44

4

1

11.75

60

35.34

1st Floor

172.51

82.84

2.40

-3.83

4

1 1/8

16.68

60

44.73

1st Floor*

214.93

78.88

2.20

4.66

4

1 1/8

15.89

60

44.73

1st Floor

239.22

67.23

2.20

12.17

4

1 1/8

14.34

60

44.73

The design anchor bolt shear strength, Pv must exceed the applied shear load PhAB (Equation 3-33).

Values of Pv, based on Equation 3-34 are given in Table D-16 for each trial panel. In every case

these values exceed PhAB. The design tensile strength, Pt and cone failure strength, Pc must exceed

the tensile stress per bolt, PtAB. Values for Pt, based on Equation 3-35 and Pc, based on Equation C-

60 are given in Table D-17 for each trial panel. In every case these values exceed PtAB. The

embedment lengths for the anchor bolts, lAB shown in Table D-17 are very large. If possible the same

anchor bolts should rather extend through the concrete beam or slab to the shear panel above or

below, thus anchoring the anchor bolts. The minimum edge distance, m to prevent side cone

concrete failure is defined based on Equation C-63 and values are given in the last column of Table

D-17. Figures D-4 through D-9 show the trial anchor design for each row in Tables D-14 through D-

17. For each floor level the asterisk indicates the selected panel design.

D-16

Previous Page

Previous Page