Design of gusset-to-column weld;

Design weld capacity to be greater than brace capacity = 238 k (1059 KN)

Column flange thickness = 0.86 in. (21.8mm)

Minimum weld size = " (6.35mm)

(AISC LRFD Table J2.4)

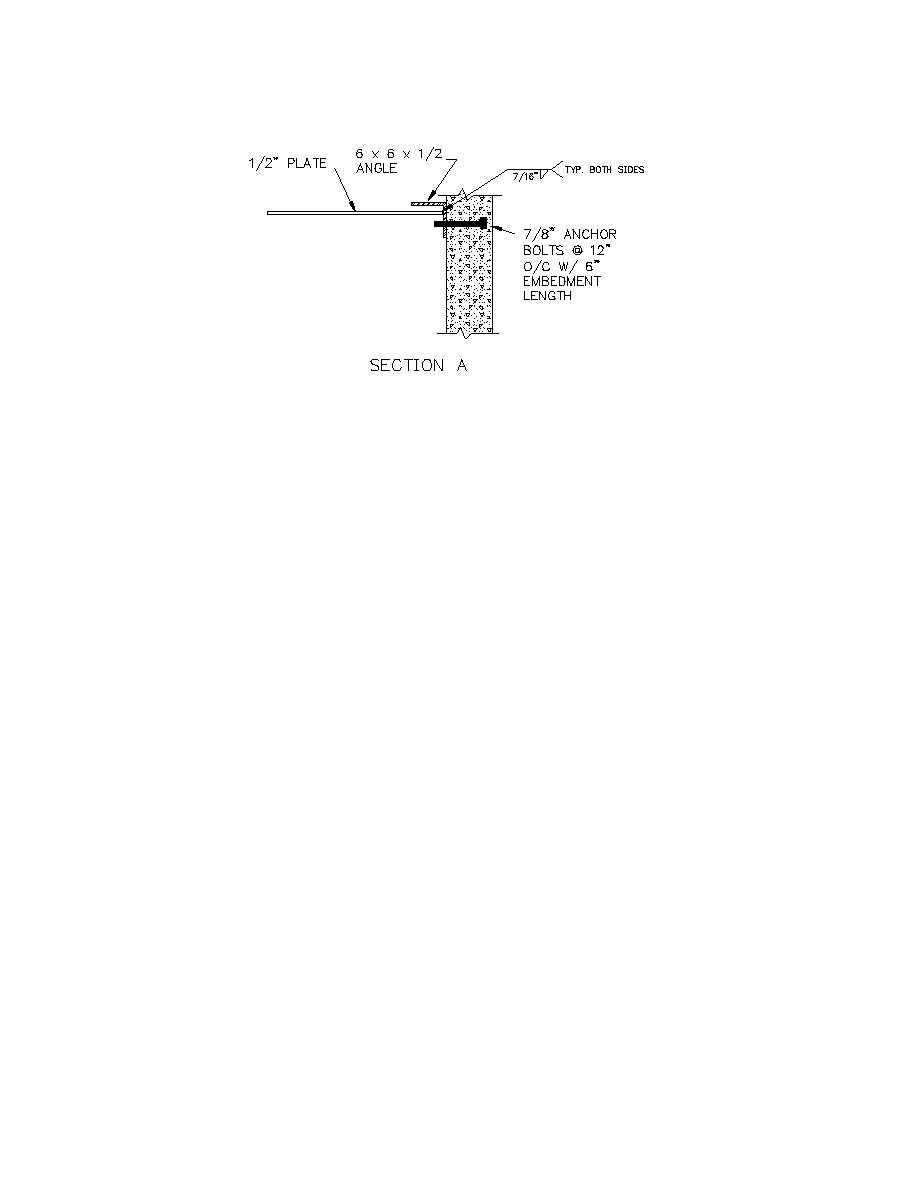

Maximum weld size = plate thickness 1/16" = 0.5-1/16 = 0.44" (11.18mm)

Use 7/16" (11.11 mm) welds (0.438")

Strength of weld; (per AISC LRFD Sec. J.4 and Table J2.5)

Weld material: φ nw = φte) (0.6 FEXX) = 0.75(0.6)(70ksi)(0.707)(0.438) = 9.75 kips / inch (1.71 KN/mm)

R

(

(governs)

Base material: φ nw = φ0.6Fu)t = (0.75)(0.5")(0.6)(58) = 13.05 kips / in (2.29 KN/mm)

R

(

Length of weld required = 238 k / (9.75 k/") = 24.4" (62 cm) (2 welds at connection, weld for full length of column

flange = 14.61" (37.11 cm) along top and bottom of plate. Total length = 2 x 14.61 = 29.22" (74.2 cm) > 24" (43.8

cm), OK

Use 7/16" (11.11mm) fillet welds along entire length of column flange on top and bottom.

H3-61

Previous Page

Previous Page