1 inch = 25.4 mm

Design of horizontal bracing connections:

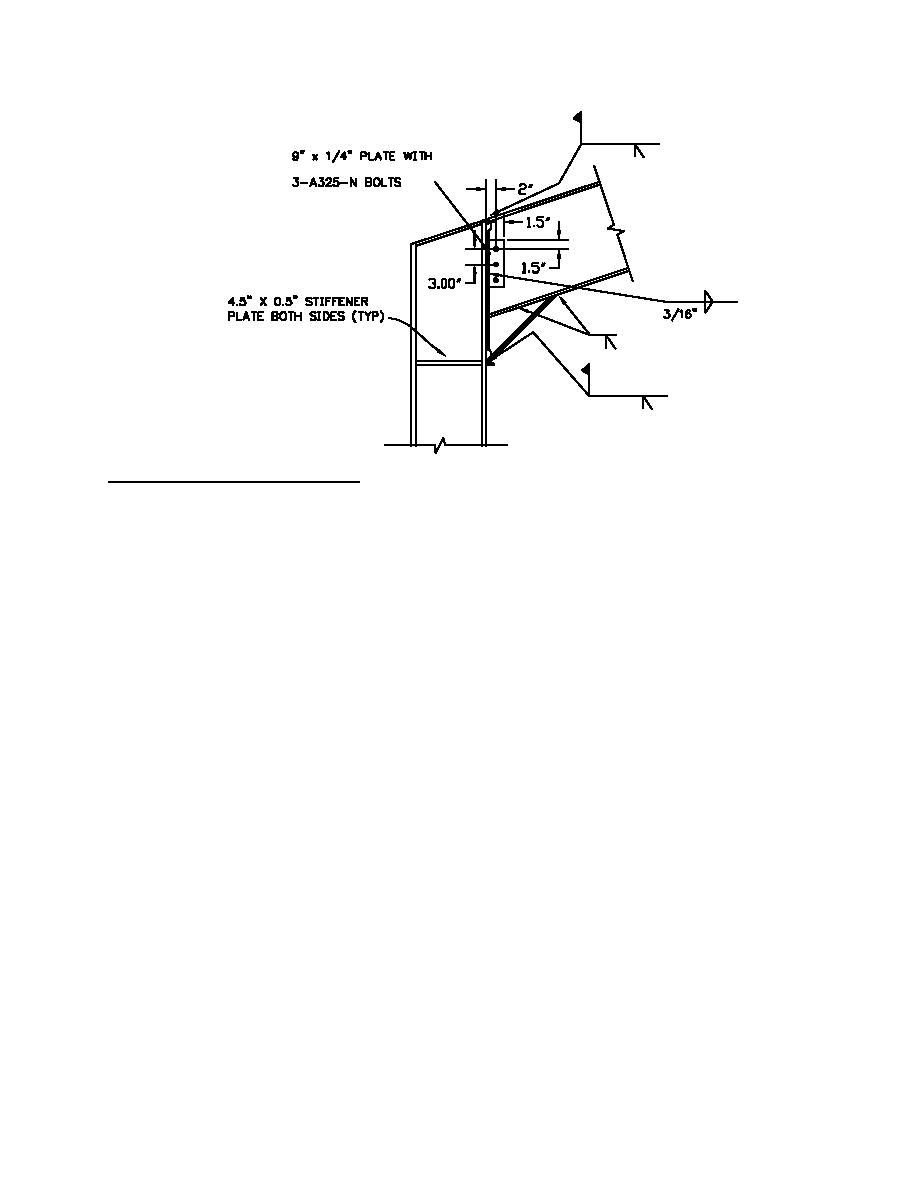

The design of these connections follows Figure 7-22.

Assume plate thickness = " (12.7 mm); thickness of brace = 0.337" (8.56mm); E70XX welds

Design of brace-to-gusset weld;

Design weld capacity to be greater than axial capacity of brace = RyFyAg = 1.5(36ksi)(4.41 in.2) = 238 k (1059 KN)

Minimum weld size = 3/16" (4.76mm)

(AISC LRFD Table J2.4)

Maximum weld size = brace thickness 1/16" = 0.337"-1/16" = 0.28" (7.11mm)

(AISC LRFD Sec. J2.b)

Use " welds (0.25") (6.35mm) 3/16<1/4<0.28, OK

Strength of weld; (per AISC LRFD Sec. J.4 and Table J2.5)

Weld material: φ nw = φte) (0.6 FEXX) = 0.75(0.6)(70ksi)(0.707)(0.25) = 5.6 kips / inch (0.98 KN/mm) (governs)

R

(

Base material: φ nw = φ0.6Fu)t = (0.75)(0.337")(0.6)(58) = 8.8 kips / in (1.54 KN/mm)

R

(

Length of weld required = 238 k / (5.6 k/") = 43" (109cm) (4 welds at connection, use 11" (27.9 cm) welds, 4 x 11

= 44 > 43)

Use 11" (27.9 cm) long " (6.35 mm) fillet welds on all four sides

Check gusset plate capacity

Tension rupture of plate: The tension rupture strength of the plate is based on Whitmore' area. This area is

s

calculated as the product of the plate thickness times the length W, shown in the sketch as a 30 degree angle offset

from the connection line. The tension rupture strength of the plate is designed to exceed the tensile strength of the

brace, 238 kips.

W = 2(11"*tan 30) + 4.5" = 17.2" (43.7 cm)

φPn = φFuAe = 0.75(58)(17.2")(0.5") = 374 k (1664 KN) > 238k (1058 KN) AISC LRFD Eq. D1-2

t

t

Block shear rupture strength of plate:

φ n = φ0.6FyAgv + FuAnt)

R

(

AISC LRFD Eq. J4-3a

φ n = 0.75(0.50)[(0.6)(36)(2 x 11"/cos 30) + (58)(17.2)] = 528 k (2349 KN) > 238 k (1058 KN)

R

H3-57

Previous Page

Previous Page