TM

5-822-14/AFJMAN

32-1019

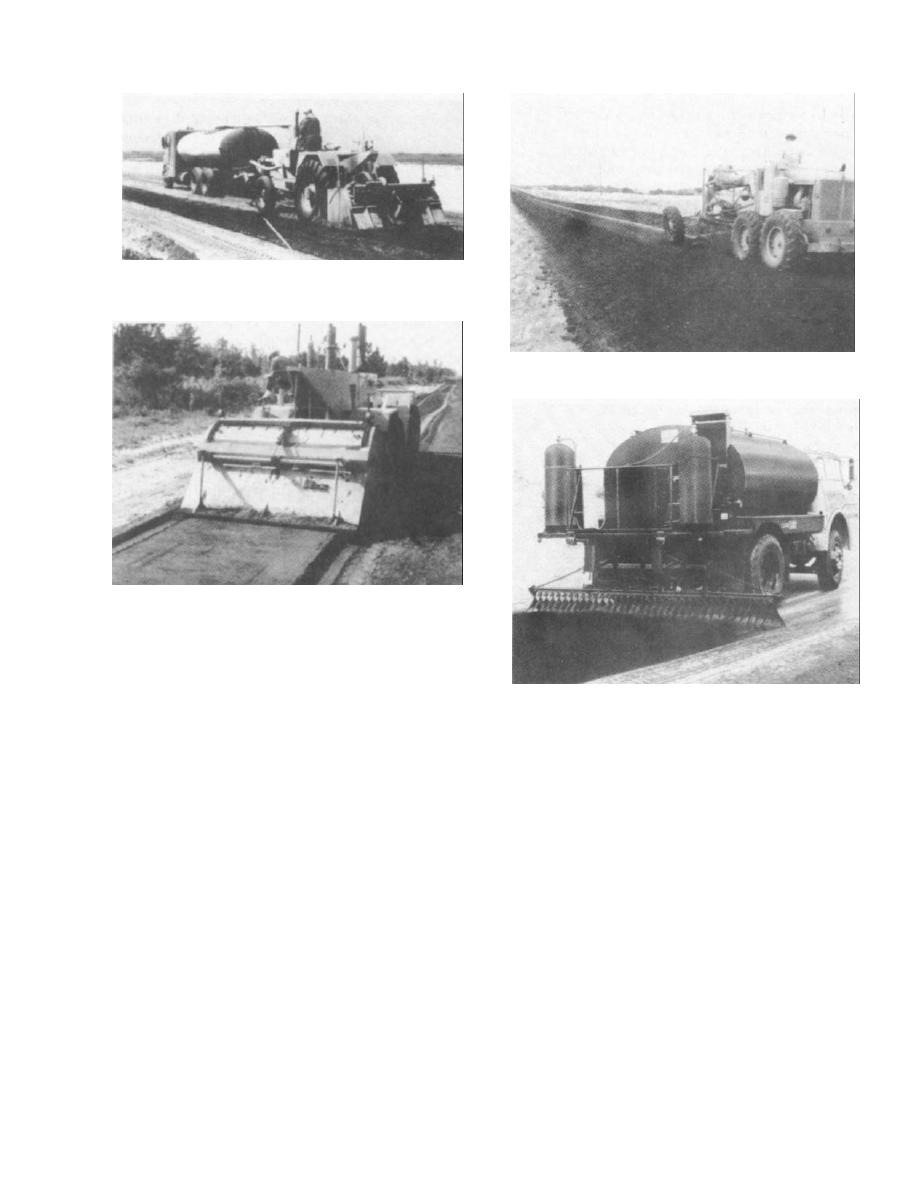

Figure 4-48. Single-shaft rotary mixer with

asphalt supply tank.

Figure 4-50. Mixing with motor grader.

Figure 4-49. Single-shaft rotary mixer without asphalt.

(c) Motor graders. Blade mixing is the on-

site mixing of asphalt and in-place materials on

the roadbed by a motor grader (fig 4-50). The

asphalt is applied directly ahead of the motor

Figure 4-51. Distributor applying asphalt.

grader by an asphalt distributor. For most effec-

tive blade mixing, the motor grader should have a

at controlled rates to as high as 3 gallons per

blade at least 10 feet long, and should have a

square yard. It is important to keep an adequate

wheelbase of at least 15 feet. Motor graders used

supply of asphalt at or near the jobsite to avoid

for final layout and finishing of the surface should

delays. In rural areas, it may be advisable to have

be equipped with smooth, rather than treaded,

an asphalt supply truck at the project.

pneumatic tires. Scarifier or plow attachments

(2) Spreading equipment. Some cold mixes

may be mounted before, behind, or both before and

may be spread to the required depth without

behind the blade.

aeration. Generally, these are open-graded mixes,

(d) Asphalt distributor. The asphalt distrib-

placed under climatic conditions that will allow

utor is a key piece of equipment in cold mix

evaporation of moisture or volatiles within a rea-

construction, particularly when rotary pulverizer

sonable time. They may be spread by a travel

mixers without built-in asphalt feed are used, or

plant, from windrows by motor grader or by large

when blade mixing is utilized. The asphalt distrib-

multipurpose equipment, such as a cutter-trimmer-

spreader. On the latter machine, guidance and

utor, either truck, or trailer-mounted, consists of

grade are electronically controlled by sensors that

an insulated tank, self-contained heating system, a

take reference from wires stretched along one or

pump, and a spray bar and nozzles through which

both sides of the roadway.

the liquid asphalt is applied under pressure onto

b. Mixed-in-Place Construction.

the prepared aggregate materials (fig 4-51). As-

(1) Windrows. Several types of cold-mix con-

phalt distributors range in performance and capa-

struction require that the aggregates be placed in

bility, with some capable of spreading up to 15 feet

4-22

Previous Page

Previous Page