TM

5-822-14/AFJMAN

32-1019

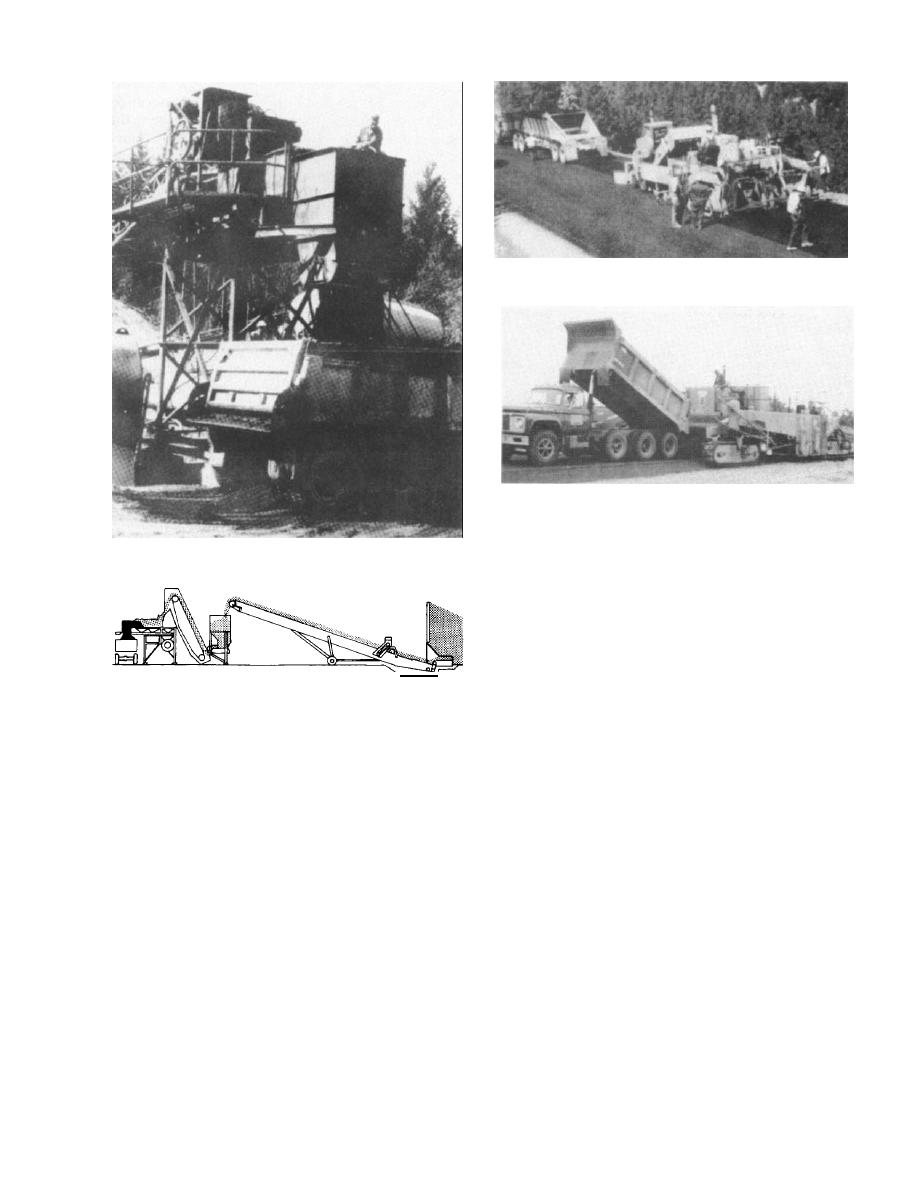

Figure 4-55. Spreading cold mix with conventional paver.

Figure 4-56. Spreading cold mix with full-width cutter-trimmer

modified for paving.

Figure 4-53. Stationary cold-mix plant.

flow of mixture from the haul truck to the

spreader must be maintained. Towed-type spread-

ers are attached to the rear of haul trucks (fig

4-58). The asphalt cold mix is deposited into the

hopper and falls directly to the surface being

paved. As the truck moves forward, the mixture is

struck off by a cutter bar, a blade, or by the screed

and is ironed out by the screed or by rollers. Many

Figure 4-54. Flow diagram of a typical

towed-type spreaders have floating screeds. In

cold-mix continuous plant.

order for the spreader to start out spreading to full

depth, blocking should be placed under the screen

volatiles without aeration by manipulation, a con-

before any mixture is dumped into the hopper. The

ventional self-propelled asphalt paver may be used

hopper should be kept full of material during

to place asphalt cold mixture (fig 4-55). A full-

paving operations to ensure a full, even spread.

width paver may be used if the plant can produce

The spreader should be towed at a uniform speed

enough mixture to keep the paver moving without

for any given setting of the screed or strike-off

start-stop operation (fig 4-56).

gate. Variations in towing speed will vary spread

(b) Spreaders. Spreading equipment such as

thickness.

d. Central Plant Mix Construction.

the Jersey Spreader and towed spreaders are

(1) Preparation of mixture. In batch-type

commonly used. The Jersey Spreader is a hopper,

plants, mixing is usually accomplished by a twin-

with front wheels, that is attached to the front end

shafted pugmill having a capacity of not less than

of a crawler or rubber-tired tractor, into which the

2,000 pounds. The correct amounts of asphalt and

asphalt mixture is dumped. The mixture falls

aggregate, generally determined by weight, are fed

directly to the road and is struck off and spread to

into the pug-mill. The batch is then mixed and

controlled thickness (fig 4-57). To begin spreading

discharged into a haul truck before another batch

the mixture at the specified depth, the tractor

is mixed. In the continuous-mixing plant, the

should be driven onto blocks or boards of a height

devices feeding asphalt, aggregate, and water, if

equal to the depth of spread and placed so that the

needed, are interlocked to maintain automatically

tractor will ride directly onto the newly-placed

the correct proportions. Typically, automatic feed-

material. Once spreading has begun, a continuous

4-26

Previous Page

Previous Page