UFC 3-240-13FN

25 May 2005

described in paragraph 6-3.1 will greatly reduce the chance of the operator getting

burned, and will allow a representative boiler water sample to be collected.

6-3.1

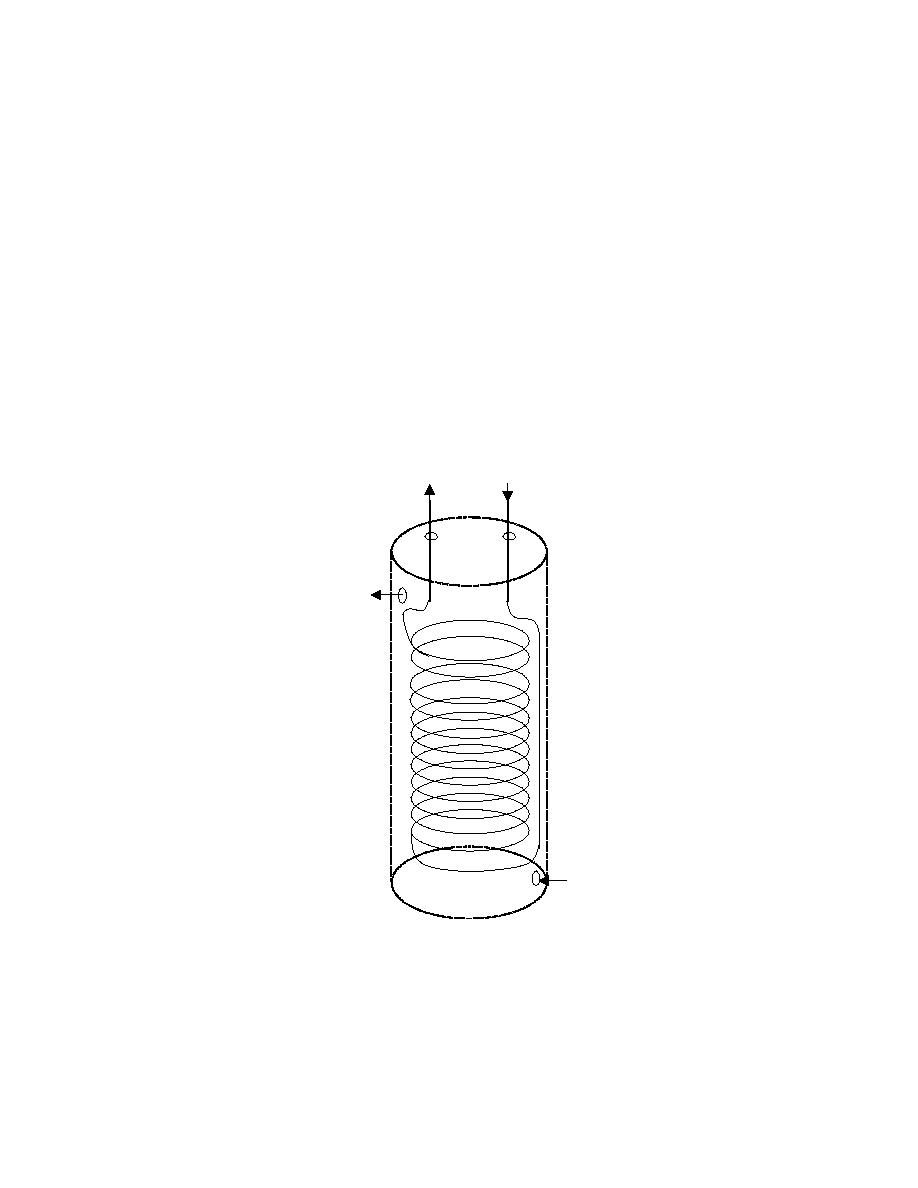

Boiler Water Sampling Cooler. A commercially available boiler water

sample cooler can be used when collecting a boiler water sample. If one is not

available, then a 4.6- to 6.1-meter long (15- to 20-foot) coil of copper or stainless steel

tubing (60 millimeters [0.25 inch]) may be used to cool the sample. The coil can be

immersed in a permanent cooling jacket as shown in Figure 6-2, or it may be immersed

in a bucket of cold water, if this does not interfere with operation of the system or create

a hazard. The flow of the boiler water sample through the coil must be slow enough so

that the cooled boiler water sample is no more than just warm to the hand

(approximately 38 C [100 oF]).

Figure 6-2. Boiler or Condensate Water Sample Cooling Coil

Cooled

Hot

Sample

Sample

Out

In

Cooling

Water

Outlet

Cooling

Water

Inlet

6-3.2

Boiler Water Sampling Procedures. The cooling water to the jacket

cooling coil is turned on before taking the boiler water sample and turned off after the

sample has been collected. The coil with boiler water is flushed with several times its

volume before collecting the sample to be tested. The cooled end of the boiler water

sample coil is then extended to the bottom of the sample bottle and at least 1 volume of

the bottle is allowed to overflow the container during the collection process. The sample

collection bottle can be plastic or glass. Glass bottles are not used if the boiler is silica

156

Previous Page

Previous Page