UFC 3-240-13FN

25 May 2005

6-1.2

Independent QA Analysis. To verify the accuracy of the in-plant testing,

as well as to provide supplemental or additional analyses, independent (third-party) QA

analytical services are incorporated as part of the plant's QA program. These services

can be more complete than routine in-plant testing and can provide a more detailed

analysis of the system conditions. Independent QA analysis is a useful tool for plant

managers and operators to verify that their systems are being maintained properly, and

is an especially important tool for government managers at sites where plant operations

have been contracted out (outsourced).

6-2

COOLING TOWER WATER SAMPLING AND TESTING

6-2.1

Cooling Water Testing Requirements. Water samples from the

recirculating cooling water systems should be tested for pH, conductivity, and inhibitor

content. Calcium hardness and methyl orange (M) alkalinity may also be tested. In

addition, follow the water testing requirements established by the supplier of the water

treatment chemicals where appropriate. Testing parameters for the makeup water

include, as a minimum, M alkalinity, conductivity, and calcium hardness. Appropriate

water testing requirements and sampling frequency are summarized in Table 6-1.

Periodic testing for chlorides in the recirculating water and makeup water may be

required to calculate the most accurate COC in an operating system.

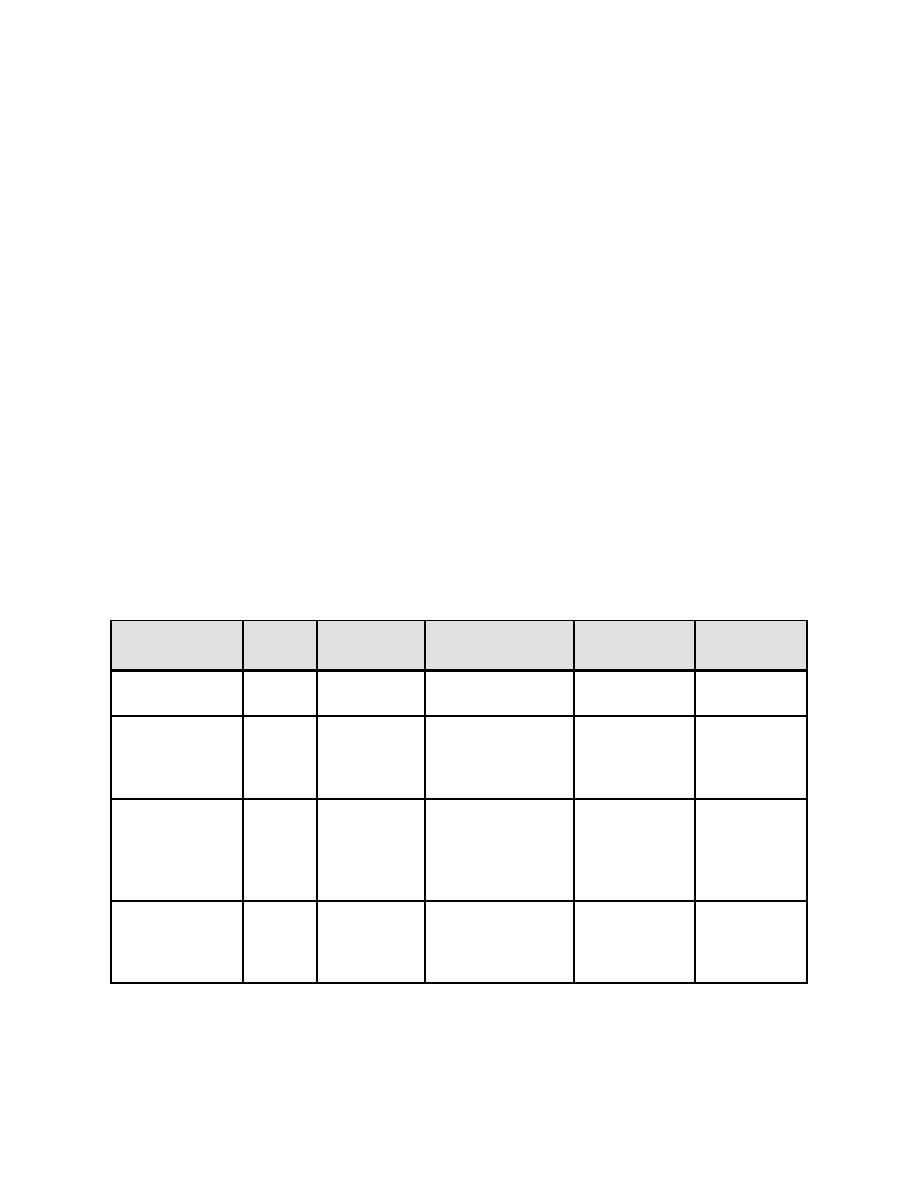

Table 6-1. Recommended Water Sample Frequency and

Testing Requirements for Cooling Tower Systems

Water

M

Conductivity

Calcium

pH

Inhibitor

(or TDS)

Hardness

Tested

Alkalinity

Makeup

--

1/W

1/W

1/W

--

water

Small CT

< 88 kW

1/W

1/W

1/W

1/W

1/W

(25 tons)

water*

Medium CT

88-352 kW

2/W

2/W

2/W

2/W

2/W

(25-100

tons)

water*

Large CT

> 352 kW

1/D

1/D

1/D

1/D

1/D

(100 tons)

water

153

Previous Page

Previous Page