UFC 3-240-13FN

25 May 2005

3-3.4

Feedwater Quality Limits. Tables 3-8 through 3-12 show feedwater

limits. The limits are specific for the type of boiler, operating pressure, and steam

application. Since feedwater is the combination of makeup water and condensate

return, recovering as much uncontaminated condensate as possible is advisable,

considering the cost of boiler water treatment and the benefits derived from both energy

and water conservation. The high purity of uncontaminated condensate minimizes the

requirement for treatment of makeup water and boiler water. The feedwater parameters

shown in Tables 3-8 through 3-12 do not specify levels for alkalinity and silica because it

is assumed that these levels in the boiler water will be limited through blowdown. In

higher pressure boilers using demineralized makeup water, alkalinity and silica will be

very low or even absent. Although not specified, it can make sense to reduce feedwater

alkalinity and silica in boilers less than 6205 kilopascals (900 pounds per square inch

gauge) to allow for an increase in COC and, consequently, to reduce chemical demand.

The tables show limits for hardness, iron, and copper. Hardness and iron can be

removed by softening the makeup water. Iron and copper may still be present in the

feedwater if they are present in the condensate due to corrosion. In many instances,

these limits cannot be met for small heating boilers (e.g., oxygen content in feedwater

softeners). The only alternative is to chemically treat boiler water and control COC, as

required.

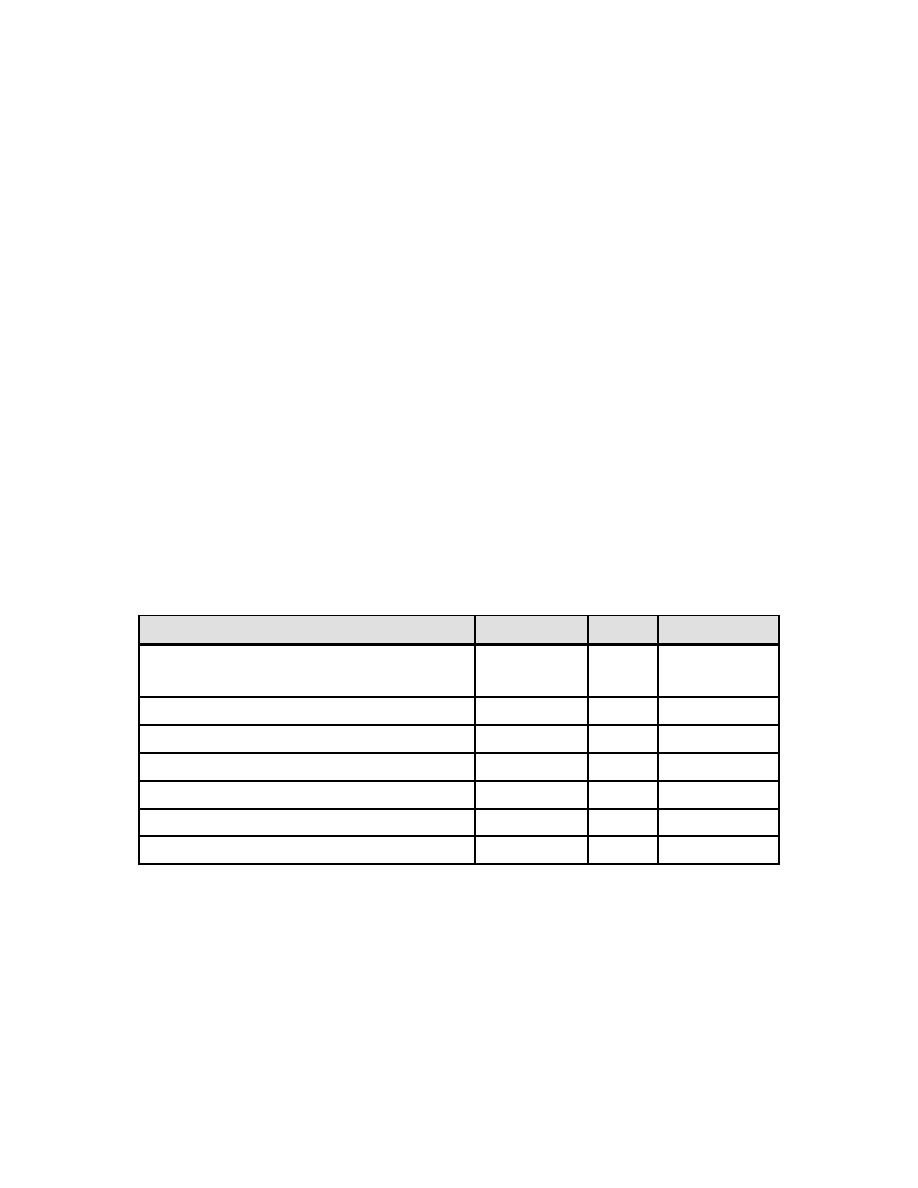

Table 3-8. Suggested Feedwater Limits for Industrial Water Tube Boiler

02068 KPa (0300 psig)

Feedwater Property

ASME

ABMA

USACE

Dissolved oxygen ppm O2 before

< 0.007

Note 6

NS

chemical oxygen scavenger addition

Total iron ppm Fe (as Fe)

< 0.1

Note 6

NS

Total copper ppm Cu (as Cu)

< 0.05

Note 6

NS

Total hardness ppm (as CaCO3)

< 0.5

Note 6

softened

pH at 25 C (77 F)

8.3-10.5

Note 6

NS

Non-volatile TOC ppm (as O2)

<1

Note 6

NS

Oily matter ppm

<1

Note 6

NS

NOTES:

1. Makeup water percentage: Up to 100% of feedwater.

2. Assumes existence of deaerator.

3. Conditions: no superheater, turbine drives, or process restriction on steam

purity.

4. Steam purity: 1.0 ppm TDS maximum.

5. NS = not specified.

6. See ABMA Standard Boiler 401

71

Previous Page

Previous Page