UFC 3-240-13FN

25 May 2005

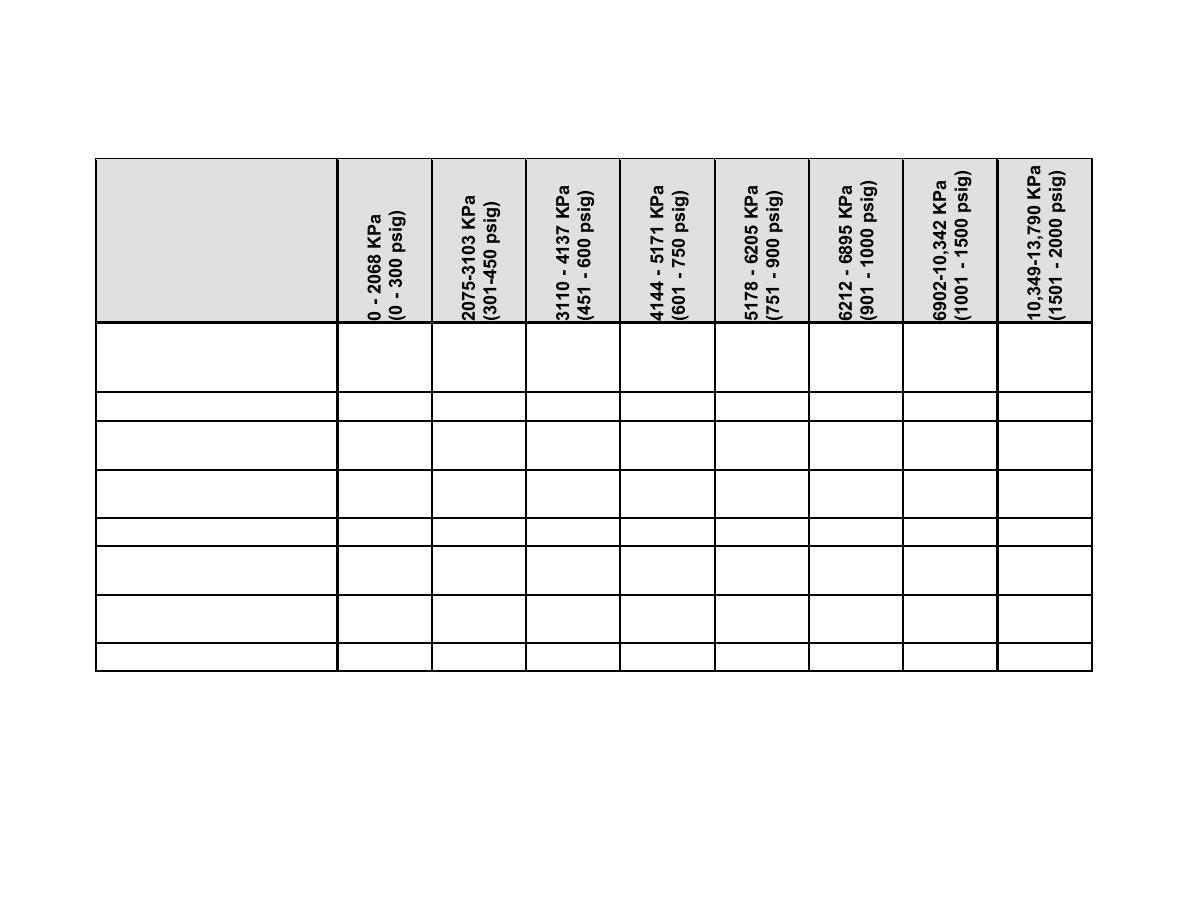

Table 3-11. ASME Feedwater Limits for Industrial Water Tube Boilers

Feedwater

Property

Dissolved oxygen (ppm O2)

before adding chemical

< 0.007

< 0.007

< 0.007

< 0.007

< 0.007

< 0.007

< 0.007

< 0.007

oxygen scavenger

≤ 0.1

≤ 0.05

≤ 0.03

≤ 0.025

≤ 0.02

≤ 0.02

≤ 0.01

≤ 0.01

Total iron ppm Fe (as Fe)

Total copper ppm Cu

≤ 0.05

≤ 0.025

≤ 0.02

≤ 0.02

≤ 0.015

≤ 0.01

≤ 0.001

≤ 0.001

(as Cu)

Total Hardness ppm

≤ 0.03

≤ 0.03

≤ 0.02

≤ 0.02

≤ 0.1

≤ 0.05

ND

ND

(as CaCO3)

pH at 25 oC (77 oF)

8.3-10.0

8.3-10.0

8.3-10.0

8.3-10.0

8.3-10.0

8.3-9.6

8.3-9.6

8.3-9.6

Chemicals for pre-boiler

NS

NS

NS

NS

NS

VAM

VAM

VAM

system

Non-volatile TOC ppm

<1

<1

< 0.5

< 0.5

< 0.5

< 0.2

< 0.2

< 0.2

(as O2)

Oily matter ppm

<1

<1

< 0.5

< 0.5

< 0.5

< 0.2

< 0.2

< 0.2

NOTES:

1.

Makeup water percentage: Up to 100% of feedwater.

2.

Assumes existence of deaerator.

3.

Conditions: Includes superheater, turbine drives, or process restriction on steam purity.

4.

Saturated steam purity target as shown.

5.

NS = not specified.

6.

ND = not detectable.

7.

VAM = Use only volatile alkaline materials upstream of a temporary water source.

73

Previous Page

Previous Page