UFC 3-240-13FN

25 May 2005

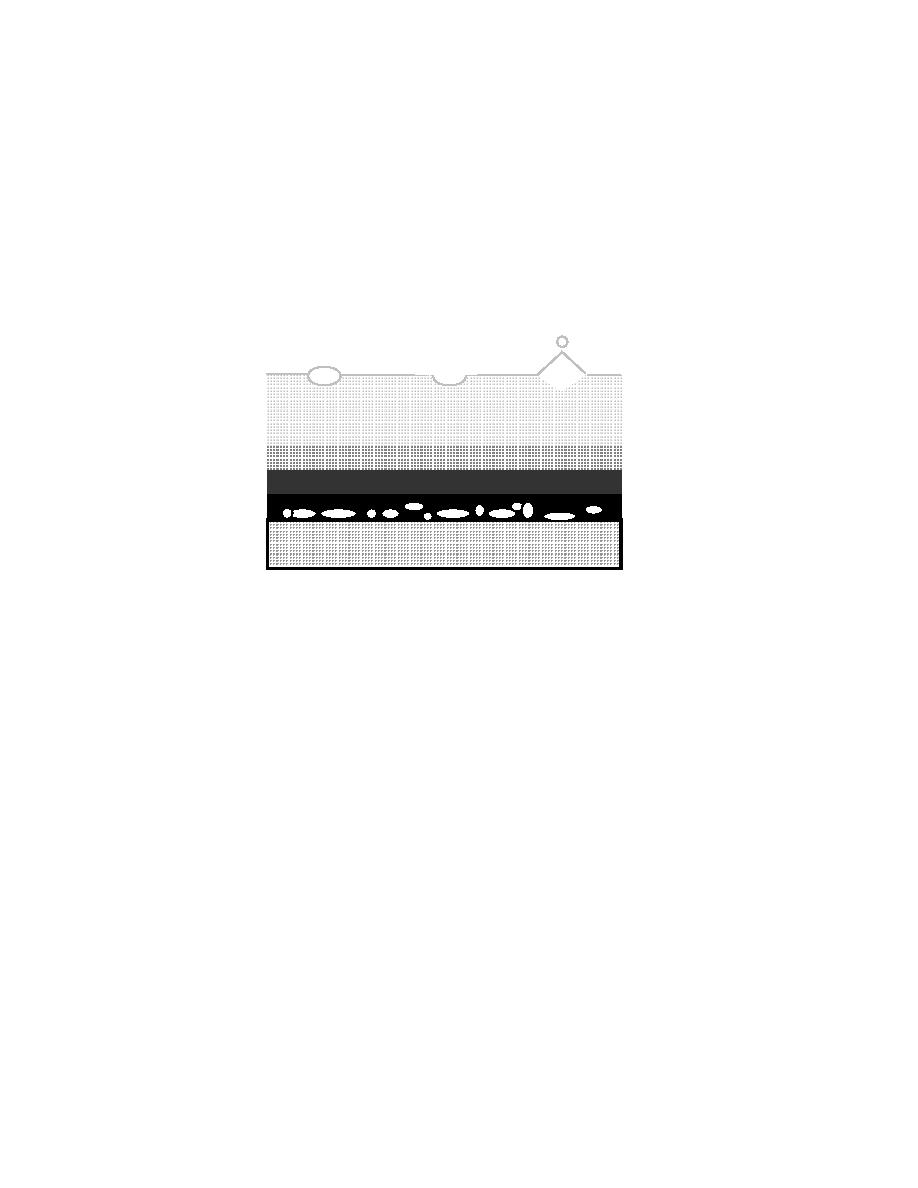

Figure 3-14. Water Boiler Mist Formation

Stage 1

Stage 2

Stage 3

Surface

Indentation

Droplet

After

Formation

Bubble

Bubble

Formation

(Mist)

Release

3-2.8.2

Foaming Carryover. The term "foaming carryover" refers to boiler water

foam and the carryover of foam into the steam. A variety of conditions can cause foam.

Excessive levels of alkalinity, TDS, SS, and at times water treatment chemicals can

interact to create foam in the boiler. Normally, maintaining the total alkalinity at less than

20% of the TDS and the total suspended solids (TSS) at less than 8% of the TDS can

control foaming to a reasonable level. In addition, adding antifoam agents to the boiler

water can control foaming. Polyamides and polyglycols are examples of antifoam

agents.

3-2.8.3

Priming Carryover. The term "priming" refers to boiler water in the steam

when, due to liquid level variations and surges in the steam drum, water is mixed with

the steam and is subsequently carried into the steam header. A mechanical problem or

mechanical properties, such as oversensitive feedwater controls, large steam demands,

or incorrect blowdown procedures, always cause priming. There is no chemical control

method available, although the addition of antifoam chemicals may help reduce the

extent of this occurrence. Boiler operations should be reviewed and modified if priming

carryover is occurring.

3-2.8.4

Silica Carryover. The term "silica carryover" refers to a situation that

occurs when silica in the boiler water volatilizes and enters the steam independently of

water carryover. The silica can then form a deposit in the condensate lines and in

process equipment when the silica condenses from the steam. When steam turbines

are used, silica deposition can be very serious, resulting in unbalancing of the steam

66

Previous Page

Previous Page