UFC 3-240-13FN

25 May 2005

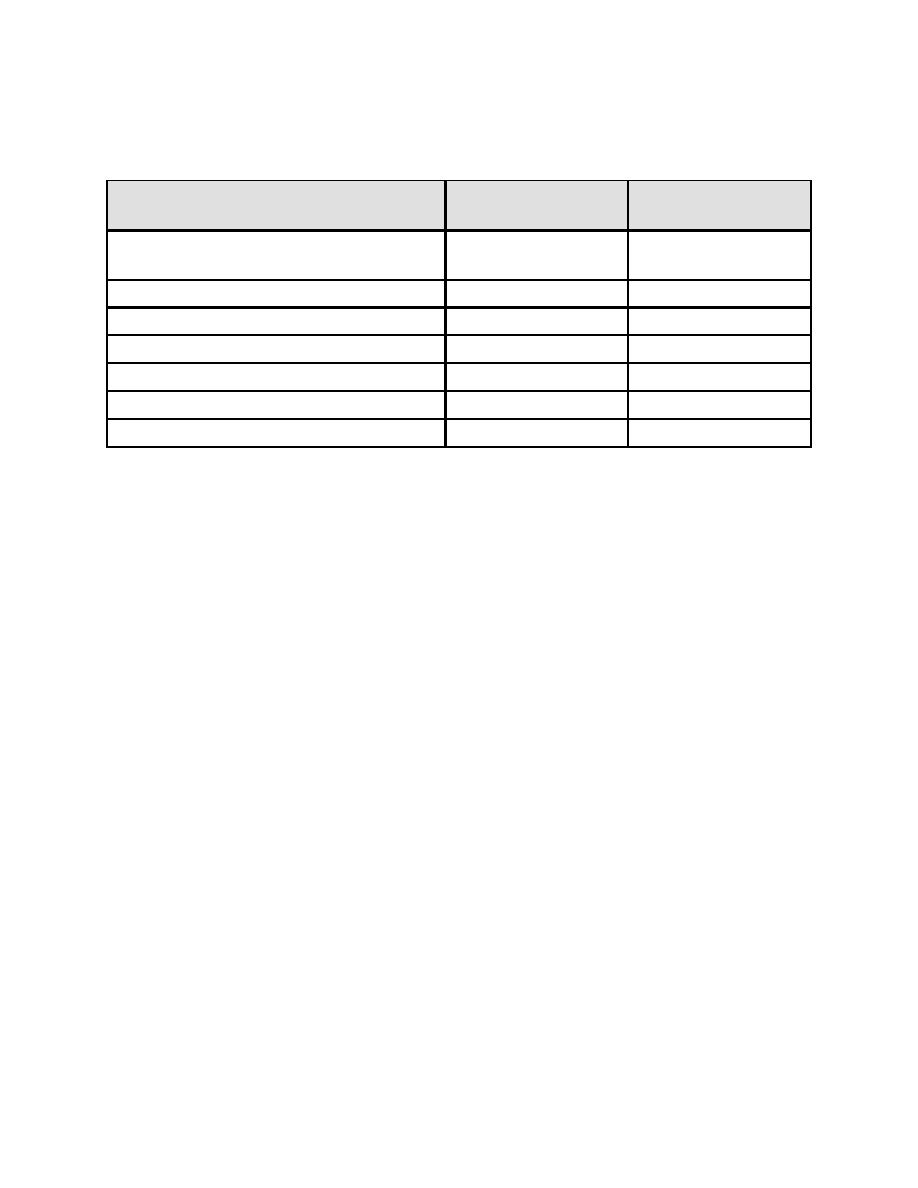

Table 3-12. ASME Suggested Feedwater Limits for

Marine Propulsion Water Tube Boiler

3103-5861 KPa

5867-8618 KPa

Feedwater Property

(450-850 psig)

(851-1250 psig)

Dissolved oxygen (ppm O2) before

< 0.007

< 0.007

chemical oxygen scavenger addition

Total iron ppm Fe (as Fe)

< 0.02

< 0.01

Total copper ppm Cu (as Cu)

< 0.01

< 0.005

< 0.1

< 0.05

pH at 25 oC (77 oF)

8.39.0

8.39.0

Chemicals for pre-boiler system

VAM

VAM

Oily matter ppm

< 0.05

< 0.05

NOTES:

1. Makeup water percentage: Up to 5% of feedwater.

2. External treatment: at sea, evaporator condensate; in port, evaporator

condensate or water from shore facilities meeting feedwater quality

guidelines.

3. Assumes existence of deaerator.

4. Saturated steam purity: 30 ppb TDS maximum, 10 ppb Na maximum, 20

ppb SiO2 maximum.

5. VAM = Use only volatile alkaline materials.

3-3.5

Boiler Water Chemistry Limits. Tables 3-13 through 3-16 show boiler

water chemistry limits. The limits are specific for the type of boiler, operating pressure,

and steam application. There are two types of limits to recognize. The first comes from

the presence of natural constituents in the feedwater (i.e., TDS or conductivity, silica,

and alkalinity). These constituents can be the controlling factor for COC. Blowdown is

ultimately required to keep their levels within limits. SS is the result of precipitation of

minerals. These are kept within limits through bottom blowdown. The second type is

treatment limits for chemicals added into the boiler (see Tables 3-17 and 3-18).

74

Previous Page

Previous Page