TM 5-814-3/AFM 88-11, Volume III

(6) Calculate sludge volume, assuming a specific gravity of 1.02 and a moisture content of 96% (4%

solids):

6,000 lb/day

Sludge volume '

' 2,360 cu ft/day (@4 mgd) ' 17,700gpd.

1.20 (62.4 lb/cu ft) (0.04)

(7) Sludge handling in this example consists of removing sludge manually from settling tank sludge

hopper, using a telescoping drawoff pipe which discharges the sludge into a sump from which it is removed

by a sludge pump (or pumps). Assume that the sludge will be wasted every 8 hours and pumps for -hour

to the digester.

daily sludge volume

2,360 cu ft

Sludge sump capacity '

'

' 787 cu ft (5,900 gal).

Number of wasting periods per day

3

Increase capacity 10 percent to compensate for scum removal volumes:

Sludgeand scum volume/wasting period

6,500

'

' 217; use 220 gpm.

Sludge pumping capacity '

30 minutes pumping/wasting period

30 min

a. Design requirements and criteria. Calculate the sludge production, using chemical addition in

primary sedimentation. Assume that addition of 60 lbs of ferrous sulfate and 700 lbs/mil gal of lime yields 70

percent suspended solids removal under the following conditions:

Flow rate = 4 mgd;

Suspended solids concentration = 300 mg/L.

The reactions that will occur are as follows:

FeSO4.7H20 + Ca(HO3) Fe(HCO3)2 + CaSO4 + 7H2O

If lime in the form of Ca(OH)2 is added, the following reaction occurs:

Fe(HCO3)2 + 2Ca(OH)2 + Fe(OH)2 + 2CaCo3 + 2H2O

The ferrous hydroxide is next oxidized to ferric hydroxide by the dissolved oxygen in the sewage:

Fe(OH)2 + O2 + 2H2O 4Fe(OH)3.

The reaction of quicklime with water alkalinity and carbon dioxide:

CaO + H2O CA(OH)2 hydrated lime;

Ca(OH)2 + CO2 CaCO3 + H2O;

Ca(OH)2 + Ca(HCO3)2 2CaCo3 + 2H2O.

b. Calculations and results. All interim calculations are computed on the basis of a flow volume of 1 mil

gal.

(1) Determine the weight of suspended solids removed:

8.34 lb/mil gal

Solids weight ' (0.70)(300 mg/L)

' 1,750 lb/mil gal;

mg/L

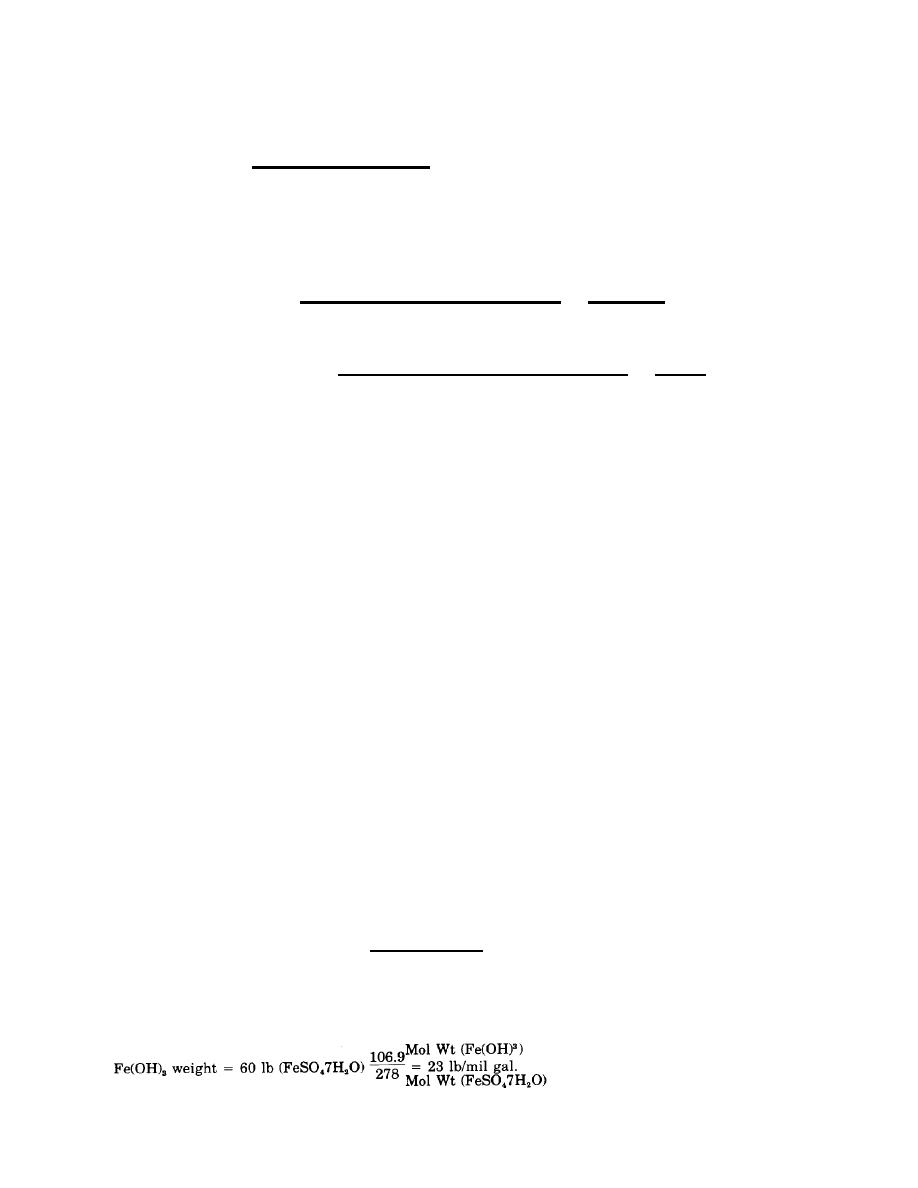

(2) Determine weight of ferric hydroxide formed from ferrous sulfate:

C-16

Previous Page

Previous Page