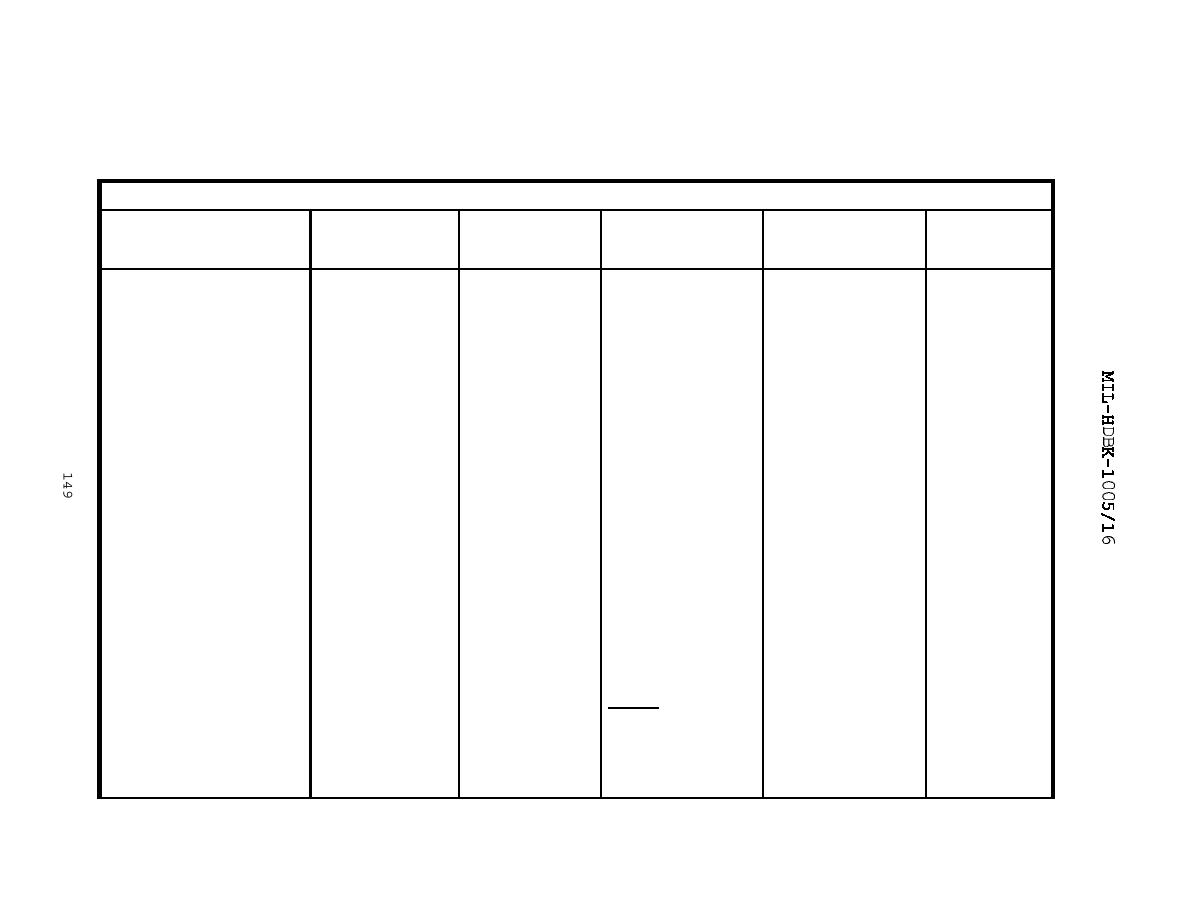

Table 15 (Continued)

Chemical-Specific Feeding Recommendations

Feeding Recommendations

Chemical-to-

Suitable

Common Name/

Best

Water Ratio for

Types

Accessory

Handling

Formula

Feeding

Continuous

of

Equipment

Materials for

Dissolving1

Solutions2

Use

Form

Feeders

Required

Aluminum,

Full strength or

----

Diaphragm pump

Storage tank,

Odor control

Hastelloy C,

any dilution

Plunger pump

water metering

titanium,

and filtration

Viton, Kel-F,

device for

PTFE, CPVC

dilution

METHANOL: CH3OH

Full strength or

----

Gear pump

Storage tank

304 ss,

Wood alcohol

any dilution

Diaphragm pump

316 ss,

denitrification

brass,

bronze,

Carpenter 20,

Hastelloy C,

buna N, EPDM,

Hypalon,

natural

rubber, PTFE,

PVDF, NORYL,

Delrin, CPVC

OZONE: O3

As generated

Gas diffused in

Ozonator

Air-drying

Glass,

Taste and odor control

Approx. 1% ozone

water under

equipment

316 ss,

Disinfection

in air

treatment

Diffusers

ceramics,

Waste treatment

aluminum,

Odor: 1 to 5 ppm

Teflon

Disinfection: 0.5 to

1 ppm

PHOSPHORIC ACID, ORTHO:

50 to 75% conc.

----

Liquid

Rubber gloves

316 St. (no F),

H3PO4

Diaphragm pump

Penton, rubber,

(85% is syrupy;

FRP3, PVC-1,

Boiler water softening

100% is

Bal. diaphragm

Alkalinity reduction

crystalline)

pump

Hypalon, Viton,

Cleaning boilers

Plunger pump

Carp. 20 ss,

Nutrient feeding

Hastelloy C

Previous Page

Previous Page