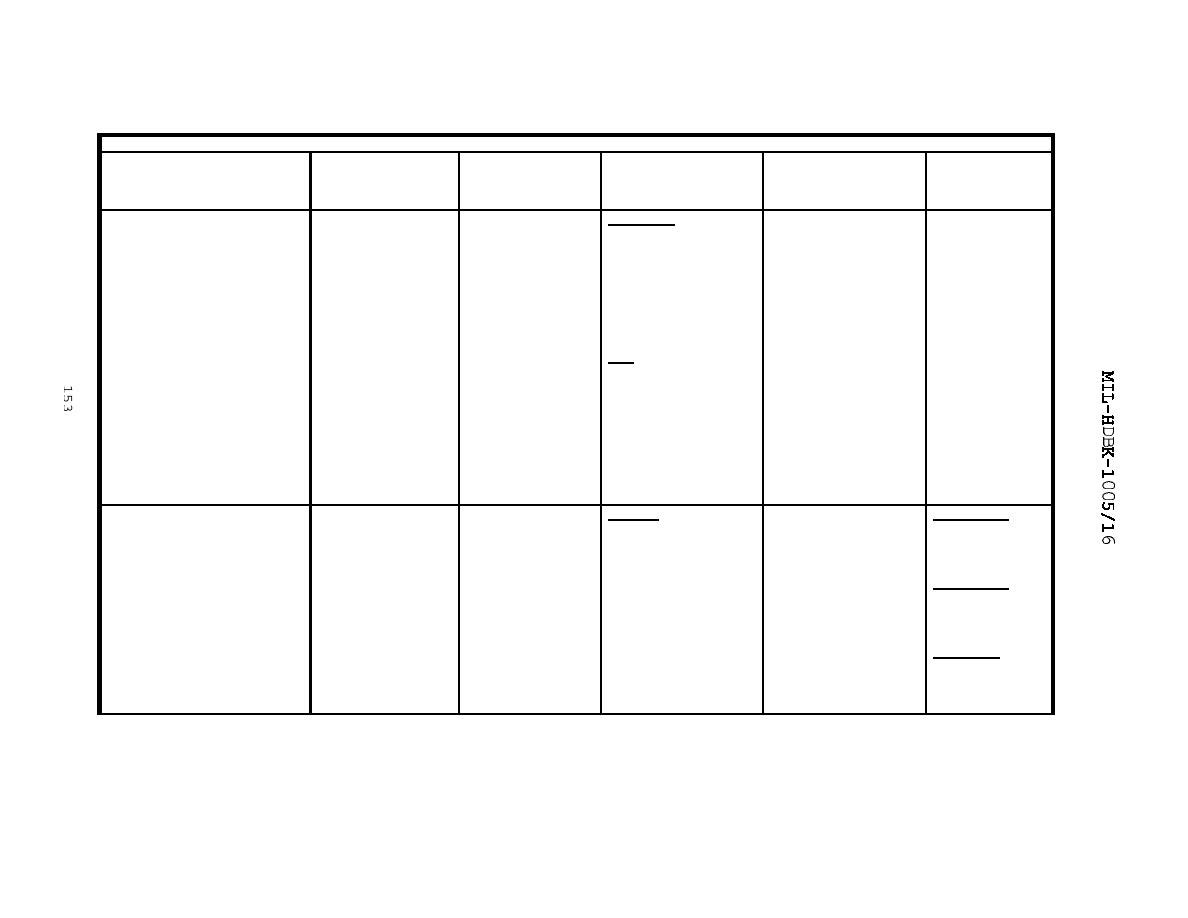

Table 15 (Continued)

Chemical-Specific Feeding Recommendations

Feeding Recommendations

Chemical-to-

Suitable

Common Name/

Best

Water Ratio for

Types

Accessory

Handling

Formula

Feeding

Continuous

of

Equipment

Materials for

1

Solutions2

Use

Form

Dissolving

Feeders

Required

1.0 gal of 12.5% Solution

Solution up to

Rubber,

Solution tanks

SODIUM HYPOCHLORITE:

Diaphragm pump

16%

(avail. Cl2)

glass, Tyril,

Foot valves

NaOCl

Rotodip

Available Cl2

soln. to 12.5

Saran, PVC-1,

Water meters

(Javelle water, bleach

Bal. diaphragm

conc.

gal of water

vinyl,

liquor, chlorine

pump

gives a 1%

Hastelloy C,

bleach)

avail. Cl2 soln.

Hypalon

Disinfection, slime

control

Bleaching

Gas

----

Gas

SULFUR DIOXIDE: SO2

Gas mask

Wet gas:

Rotameter

Dechlorination in

Glass,

SO2 feeder

disinfection

Carp. 20 ss,

Filter bed cleaning

PVC-1, Penton,

About 1 ppm SO2 for

ceramics,

each ppm Cl2

316 (G),

(dechlorination)

Viton, Hypalon

Waste treatment

Cr +6 reduction

SULFURIC ACID: H2SO4

Soln. at desired

Dilute to any

Goggles

Conc.>85%:

Liquid

Plunger pump

(Oil of Vitriol,

dilution

desired conc.:

Rubber gloves

Steel, iron,

Diaphragm pump

Vitriol)

H2SO4 has a high

NEVER add water

Aprons

Penton, PVC-1

Bal. diaphragm

pH adjustment

heat of soln.

to acid but

Dilution tanks

(good), Viton

pump

Activation of silica

rather always

40 to 85%:

Rotodip

Carp. 20,

add acid to

alkaline wastes

PVC-1, Penton,

water.

Viton

2 to 40%:

Carp. 20,

FRP3, glass,

PVC-1, Viton

Previous Page

Previous Page