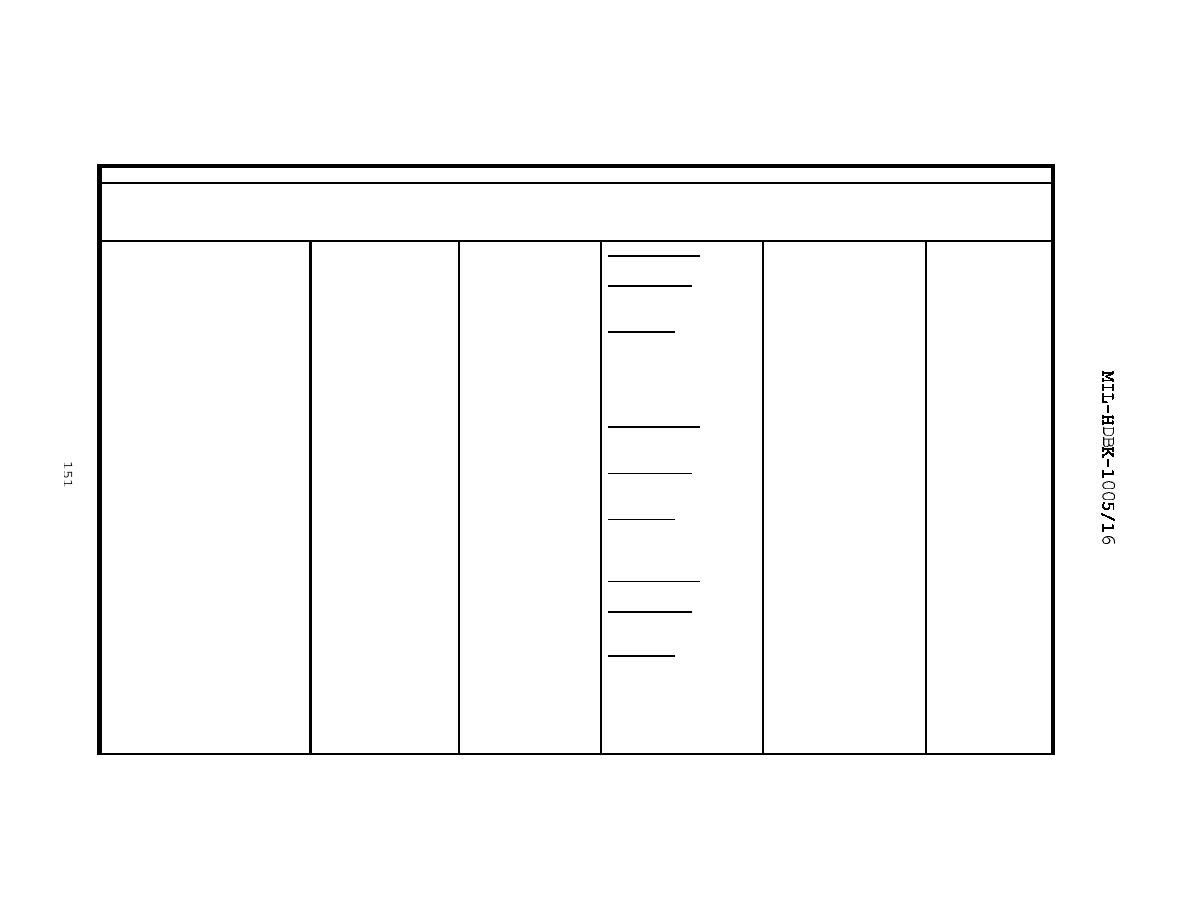

Table 15 (Continued)

Chemical-Specific Feeding Recommendations

Feeding Recommendations

Chemical-to-

Suitable

Common Name/

Best

Water Ratio for

Types

Accessory

Handling

Formula

Feeding

Continuous

of

Equipment

Materials for

1

Solutions2

Use

Form

Dissolving

Feeders

Required

Granular or

Dry 0.5 lb/gal

Gravimetric

SODIUM ALUMINATE:

Hopper agitators

Iron, steel,

Soln. dilute as L-I-W

soln. as

for dry form

rubber, 316

Na2Al2O4, anhy.

Volumetric

received

desired

st. s.,

(soda alum)

Helix

Std. grade

Penton,

Ratio Na2O/Al2O3

Universal

produces sludge

concrete,

1/1 or 1.15/1 (high

Solution

on dissolving

Hypalon

purity)

Rotodip

Also Na2A12O43H2O

Diaphragm pump

hydrated form

Plunger pump

Coagulation

Boiler H2O treatment

Granules or

0.3 lb/gal

Gravimetric

SODIUM BICARBONATE:

Hopper agitators

Iron & steel

L-I-W

powder plus TCP

and non-flood

(dilute

NaHCO3 (baking soda)

Belt

(0.4%)

rotor for powder,

solns.:

Activation of silica

Volumetric

if large storage

caution),

pH adjustment

Helix

hopper

rubber, Saran,

Universal

st. steel,

Solution

Hypalon, Tyril

Rotodip

Diaphragm pump

Plunger pump

SODIUM BISULFITE,

Hopper agitators

Glass, carp.

Crystals (do not

0.5 lb/gal

Gravimetric

L-I-W

for powdered

20 ss,

let set)

ANHYDROUS:

Volumetric

grades

PVC-1, Penton,

Storage

Na2S2O5 (NaHSO3)

Helix

difficult

Vent dissolver to

Uscolite,

(Sodium pyrosulfite,

316 st., FRP3,

Universal

outside

sodium meta-bisulfite)

Solution

Tyril, Hypalon

Dechlorination: about

Rotodip

Diaphragm pump

1.4 ppm for each

Plunger pump

ppm C12

Bal. diaphragm

Reducing agent in waste

pump

treatment

(as Cr)

Previous Page

Previous Page