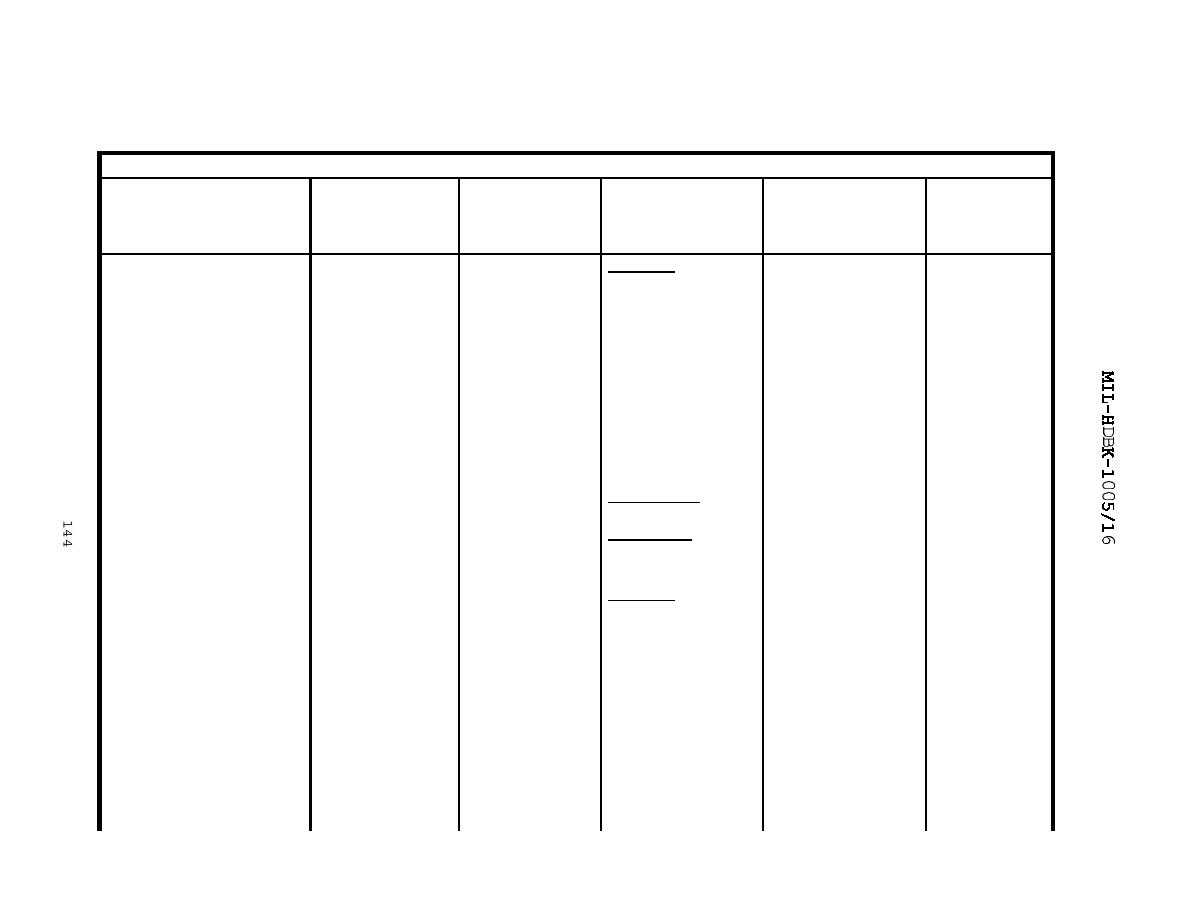

Table 15

Chemical-Specific Feeding Recommendations

Feeding Recommendations

Suitable

Chemical-to-

Handling

Accessory

Best

Water Ratio for

Types

Common Name/

Materials for

Equipment

Feeding

Continuous

of

Formula

Solutions2

Dissolving1

Required

Form

Feeders

Use

Solution

Dilute to

Full strength

ALUM: A12(SO4)3XH2O

Tank gauges or

Lead or

between 3% and

under controlled

Rotodip

scales

rubber-lined

Liquid

15% according

temp. or dilute

tanks,

Plunger pump

Transfer pumps

1 gal 36Be = 5.38 lb

to application

to avoid

Duriron,

of dry alum: 60F

Diaphragm pump

Storage tank

FRP3, Saran,

conditions,

crystallization

Coag. at pH 5.5 to 8.0

1700 pump

mixing, etc.

PVC-1, vinyl,

Temperature

Minimize surface

Sludge conditioner

Hypalon,

control

L-I-W

evap.: causes

Epoxy, 16 ss,

Precipitate PO4

flow problems

Eductors or

Carp. 20 ss,

dissolvers for

Keep dry alum

Tyril

dilution

below 50%

to avoid

crystallization

ALUMINUM SULFATE:

Ground,

0.5 lb/gal

Dissolver

Gravimetric

Lead, rubber,

FRP3, PVC-1,

A12(SO4)314H2O

granular, or

Belt L-I-W

Dissolver

Mechanical mixer

rice

316 ss, Carp.

(Alum, filter alum)

Volumetric

detention time

Scales for

20 ss, vinyl,

Helix

Powder is dusty,

5 min. for

Coagulation at pH 5.5

volumetric

Hypalon

to 8.0

arches, and is

ground (10 min.

Universal

feeders

Epoxy,

floodable4

for granules)

Dosage between 0.5 to

Solution

Ni-Resist

9 gpg

Plunger pump

glass,

Precipitate PO4

Diaphragm pump

ceramic,

polyethylene,

1700 pump

Tyril,

Uscolite

AMMONIA ANHYDROUS: NH3

Dry gas or as

----

Gas feeder

Scales

Steel,

aqueous soln.:

Ni-Resist,

(Ammonia)

see "Ammonia,

Monel,

Chlorine-ammonia

Aqua"

316 ss,

treatment

Penton,

Anaerobic digestion

Neoprene

Nutrient

Previous Page

Previous Page