TM 5-813-3/AFM 88-10, Vol 3

valves, surface and backwash facilities, and operating

Location

consoles. provide essential instrumentation for each

Water level upstream, first-stage flow divi-

filter. Provide sampling taps for each filter. Plant lay-

sion weir

out and hydraulic design should be such that addition-

Water level downstream, first-stage flow

al filters can be readily added as required.

division weir

i. Clearwell. Clearwell (filtered water storage)

(Loss: raw water pipe friction + velocity

capacity should be related to the available or proposed

head in pipe

distribution system storage (ground and elevated). As

Water level in first-stage rapid-mix basin

an approximation for this design example, clearwell

(Loss: rapid-mix to first-stage flocculator-

capacity of at least 0.6 million gallons could be pro-

clarifier

vided. This is about 25 percent of the plant's daily pro-

Water level in first-stage flocculator basin

duction when operating at 2.2 mgd (design capacity).

(Loss: flocculator to sedimentation basin

Greater clearwell capacity may prove advantageous

Water level in first-stage sedimentation

depending on water demand patterns and plant oper-

basin

ating schedule. The clearwell is commonly located

First-stage sedimentation basin overflow

adjacent to the filters and at an elevation permitting

level

gravity flow to it. This usually requires an under-

(Loss: sedimentation basin weirs, launder

ground structure. An alternative arrangement consists

and piping to second-stage division struc-

of a sump following the filters, equipped with auto-

ture

matically controlled transfer pumps, which discharge

(Loss: second-stage division structure

to an above-ground tank or basin. Underground clear-

Water level in second-stage rapid-mix basin

wells are commonly constructed or reinforced con-

(Loss: rapid-mix to second-stage floccula-

crete. For above-ground installations, steel tanks can

tor clarifier

be used. Regardless of the arrangement, the clearwell

Water level in second-stage flocculator

should be an independent structure, watertight, and

(Loss: flocculator to sedimentation basin

protected against birds, animals and insects. Vents

Water level in second-stage sedimentation

must be installed and protected against surface and

basin

rainwater entry, birds, insects and animals. A pro-

Second-stage sedimentation basin overflow

tected, free-discharge, overflow should also be pro-

level

vided. The overflow must not be connected to any

(Loss: sedimentation basin weirs, launder

sewer or drain. Access to the interior of the clearwell is

and filter influent piping

required.

Water level in filters

The access opening should be curbed at least 6 inches

Top of anthracite (- 7.00)

above the roof surface and be equipped with a hinged,

Filter operating floor level (+3.67)

overlapping, watertight, locking cover. As a general

(Filter freeboard at second-stage basin over-

rule, the clearwell should be located at least 50 feet

flow level

from sewers or drains. The area around the clearwell

Bottom of filter cells (- 15.00)

should be fenced and the site graded so that surface

(Maximum loss through filter media, gravel

drainage is away from the structure. Where winters

underdrains, effluent piping and controls

are severe, special consideration must be given to the

Maximum water level in clearwell

design of vents and overflows to prevent freeze-up as a

(Overall head loss during emergency oper-

result of vapor condensation. A water level sensing in-

ation: first-stage division structure--

strument with readout in the plant control center

maximum clearwell level

should be provided. This can operate in conjunction

By utilizing higher-than-normal chemical dosages, the

with the previously described maximum level control-

plant can be operated under emergency overload con-

alarm circulation and lengthened chlorine contact

ditions and still produce water meeting drinking water

time.

standards. In deriving the above data, the following

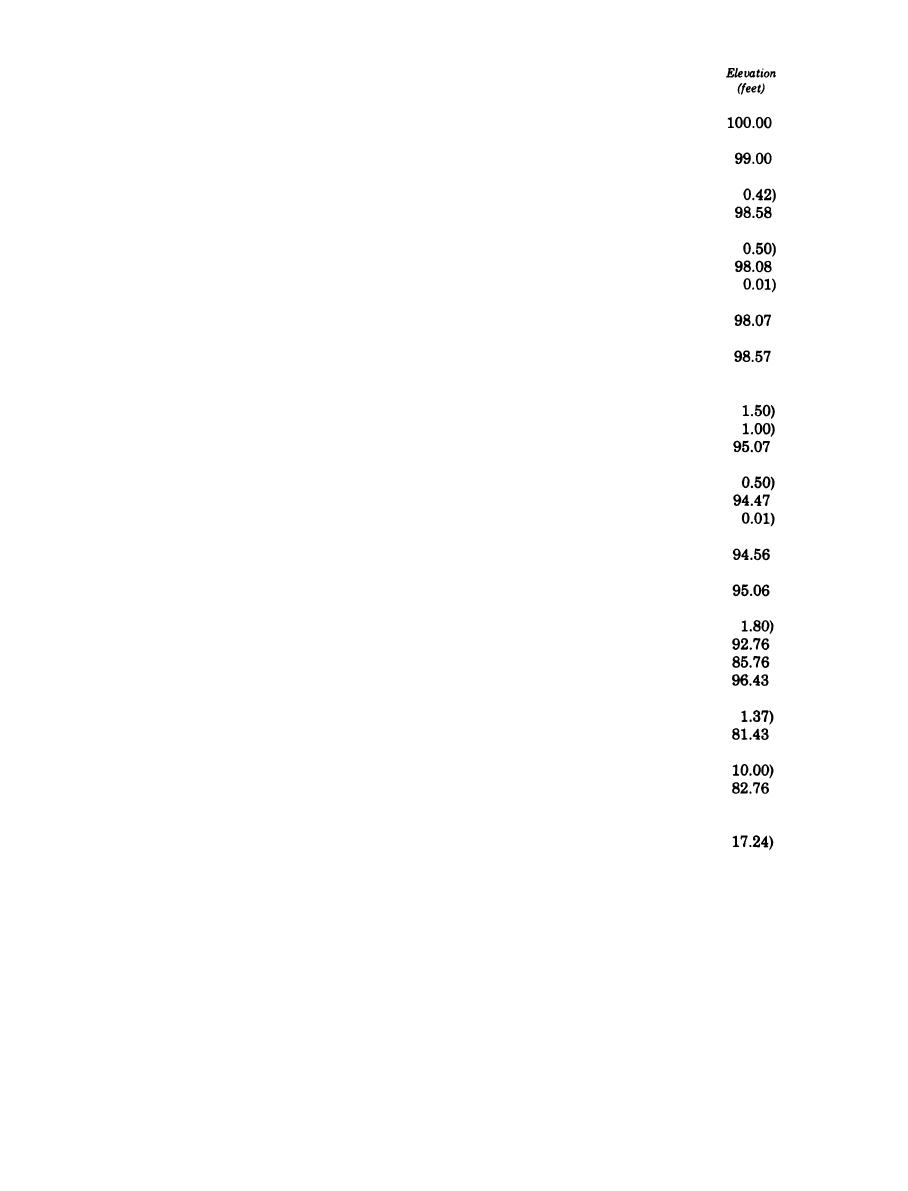

j. Hydraulic profile. The hydraulic interrelationship

emergency conditions were assumed:

of major plant units must be carefully considered. In

(1) All raw water pumps are operated, giving a

general, the hydraulic design of the plant should be on

raw water flow of 3.3 mgd, which is 1.5 times nominal

the side of ample flow capacity so that, under emer-

design rate.

gency conditions, water can be treated and filtered at

(2) Both first- and second-stage rapid mix, floc-

considerably more than the normal rate with all filters

culation, and sedimentation units on one side of plant

in service. The approximate elevation data, given in

are out of service.

the following tabulation, establish the emergency-

-

(3) Reference elevation of water in first-stage flow

operation hydraulic profile:

B-4

Previous Page

Previous Page