TM 5-813-3/AFM 88-10, Vol 3

nese removal. The high pH achieved insured essential-

ly complete precipitation of any iron and manganese

present in the raw water.

(d) Clarification. Lime softening provides excel-

lent coagulation and clarification as a result of the pre-

cipitation of magnesium hydroxide plus a large

amount of calcium carbonate.

(9) Softening plant design. The equipment, bas-

ins, and filters required for lime, lime-soda ash, lime-

caustic, or split treatment softening are generally

similar to the facilities used in conventional coagula-

tion-filtration plants. Two stages of treatment are

usually advisable. The design of a lime-soda ash or

similar softening plant is a complex and difficult task

requiring the services of engineers experienced in proj-

ects of this kind. Their assistance should be sought in

early stages of project planning.

(a) Mixing equipment, One problem encoun-

tered at softening plants is vibration of rapid mixing

devices due to nonuniform deposits of calcium carbon-

ate scale._ Frequent cleaning of the mixer may be re-

quired. The frequency of such cleaning can be reduced

by recirculation of previously precipitated calcium car-

bonate sludge from the settling basin to the rapid-mix

chamber. Parshall flumes can serve as mixing devices.

(b) Flocculation and clarification. Each separate

stage of flocculation and clarification should have a to-

tal detention time at design flow of about 2.5 hours, 30

minutes for flocculation and 2 hours for clarification.

Average depths of both flocculation and clarification

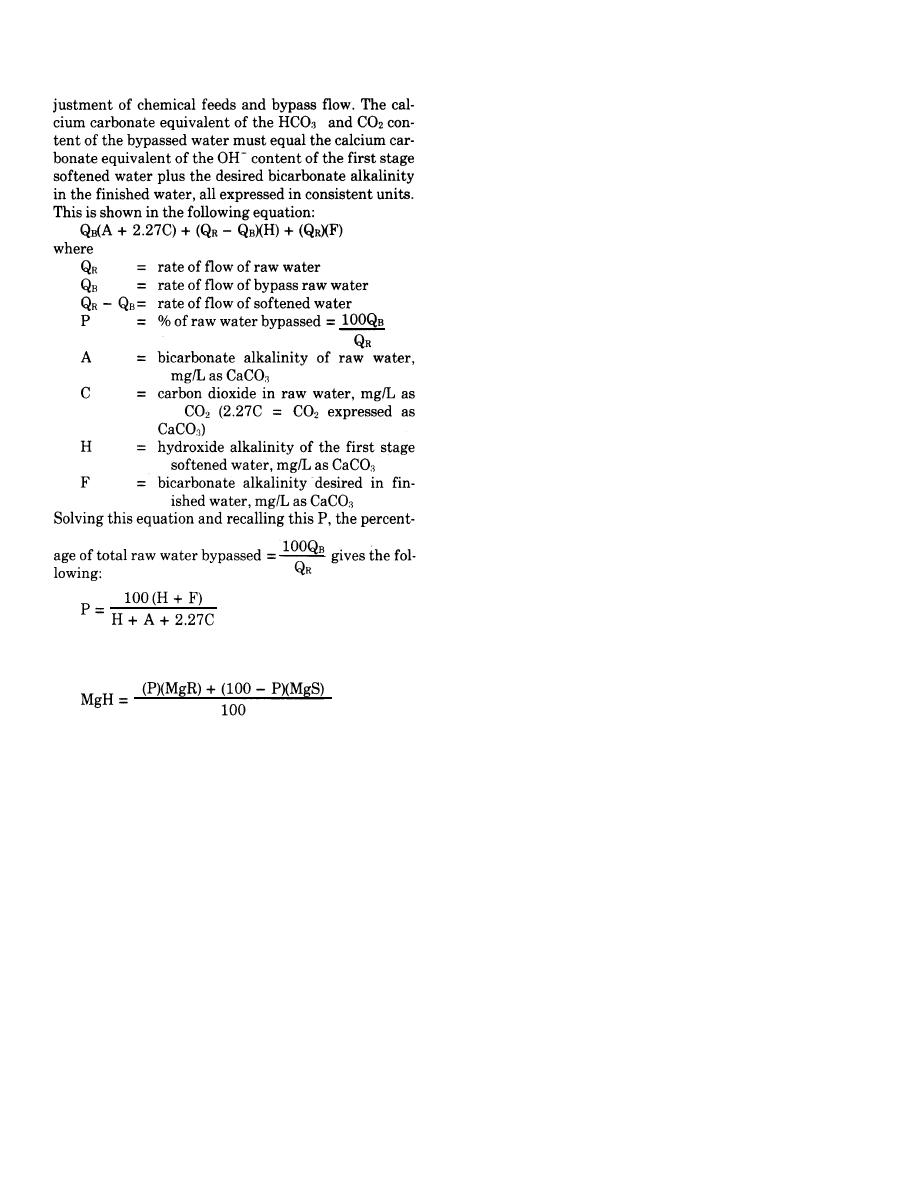

The magnesium hardness of the finished water can be

units should be 8 to 15 feet. The overflow rate in clari-

estimated from the following:

fiers at design flow should be about 0.75 gpm per

square foot.

(c) Sludge removal and recirculation. First-stage

settling basins shall have mechanical sludge removal

MgH = magnesium hardness of finished water in

equipment. Such equipment is also desirable in the sec-

mg/L

ond-stage basins which follow recarbonation. Sludge

MgS = magnesium hardness of the first stage sof-

recirculation is generally desirable except during oc-

tened water in mg/L

currences of severe taste and odor problems. Recycling

MgR = magnesium hardness of the raw water in

of a portion of the settled sludge, which is high in cal-

mg/L

cium carbonate, to the rapid-mix chamber is effective

P = `/o bypass water

in promoting the softening reactions, especially car-

(8) Incidental benefits of lime softening.

bonate precipitation. Where_ presedimentation is em-

(a) Disinfection. Excess lime provides excellent

ployed, recycling sludge to the presedimentation basin

bactericidal treatment, especially at pH values above

influent will enhance the performance of the presedi-

10.5. Lime treatment, while not a substitute for chlori-

mentation basin.

(d) Solids contact units. Solids contact type ba-

nation, is an effective supplement,

(b) Reduction of dissolved solids. Removal of

sins may be used at many softening plants, particular-

carbonate hardness by lime treatment results in reduc-

ly those treating ground water, These basins provide

tion in the total dissolved solids content of the water.

the functions of mixing, sludge recirculation, sedimen-

All reaction products of lime softening are relatively

tation and sludge collection in a simple compact unit.

insoluble. The lime added to the water, as well as the

Basins of this type, if properly sized, will provide ef-

carbonate hardness constituents in the water, are

fective softening and clarification treatment. Overall

largely precipitated.

basin depths of 10 to 15 feet should be used, and the

unit should be designed so that the softening slurry is

is also highly effective as a means of iron and manga-

recirculated through the center chamber at a rate of

2-22

Previous Page

Previous Page