TM 5-813-3/AFM 88-10, Vol 3

however, the net effect will be as illustrated by reac-

sive. In lime softened wasters, it is desirable that the

tions 2 through 7.

magnesium hardness be reduced to 40 mg/L or less.

(2) Chemical requirements.

The residual calcium hardness should be approximate-

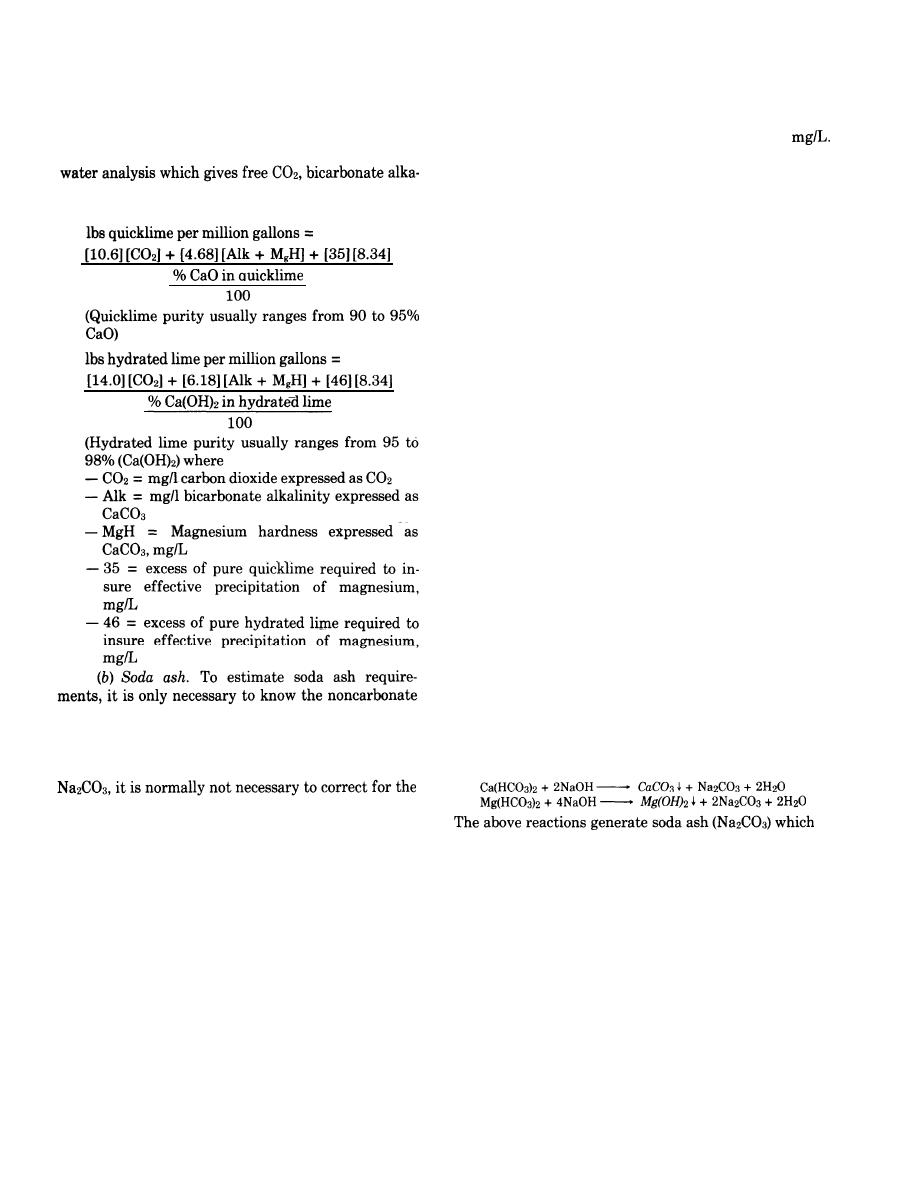

(a) Lime. A reasonably accurate estimate of lime

ly 50 mg/L and the alkalinity also about 50

requirements for softening can be computed from a

Some ground water supplies contain no noncarbonated

hardness. For such waters, lime treatment alone will

linity and, magnesium. Requirements of quicklime or

suffice for softening.

hydrated lime can be computed as follows:

(4) Sludge production. The lime-soda ash soften-

ing process produces chemical sludge composed princi-

pally of calcium carbonate and magnesium hydroxide.

As withdrawn from sedimentation basins equipped for

mechanical sludge removal, the proportion of dry sol-

ids in the sludge will generally fall within the range of

2 to 10 percent. The weight of dry solids produced by

softening reactions will average approximately 2.5

times the weight of commercial quicklime used. For

hydrated lime, softening solids produced will be rough-

ly twice the weight of commercial hydrated lime em-

ployed. Fairly accurate values of total solids produc-

tion at an operating plant can be developed utilizing a

mass balance which takes into consideration the sus-

pended solids in the raw water, the quantity of dis-

solved calcium and magnesium in the raw and finished

water, the quantity and purity of lime applied, the

quantity of coagulant used, and the stoichiometry of

the softening and coagulation reactions. Means of dis-

posal of waste solids from softening plants must re-

ceive careful consideration at an early stage of treat-

ment plant design. See chapter 6.

(5) Lime-caustic soda process. An alternative soft-

ening process, sometimes used, is the lime-caustic soda

process. The process is worth consideration when con-

siderable reduction in noncarbonated hardness is re-

quired. Application of the process involves substitu-

tion of caustic soda (sodium hydroxide) for soda ash

and part of the lime. The remaining lime reacts with

hardness of the raw water and to establish the amount

carbonate hardness constituents as previously indi-

of noncarbonated hardness to be left in the finished wa-

cated. The caustic soda also reacts with carbonate

ter. The latter is termed residual noncarbonated hard-

hardness as follows:

ness. Inasmuch as most commercial soda ash is 990/0+

purity of this chemical.

lbs soda ash per million gallons = [8.34] [NCH-R]

will reduce the noncarbonated hardness as previously

where

indicated. All of the reaction products are chemically

-- NCH = mg/L of noncarbonated hardness

identical to those obtained by the use of lime and soda

-- R = mg/L of residual noncarbonated hardness

ash. The amount of caustic soda required can be calcu-

(The term [NCH-R] is the mg/L of noncarbonated

lated from the theoretical quantities of pure lime and

hardness removed)

soda ash required. Less calcium carbonate sludge is

(3) Characteristics of lime-softened water. The

formed with the lime-caustic soda process. This may be

carbonate hardness of the water, after application and

an advantage if softening sludge disposal is a problem.

reaction of the softening chemicals plus sedimentation

For water softening purposes, caustic soda should be

and filtration, should be approximately 50 mg/L. The

purchased as a 50 percent solution containing 6.38

total hardness will consist of the carbonate hardness,

pounds of pure NaOH per gallon. A 50 percent solution

50 mg/L, plus the residual noncarbonated hardness that

must be stored at temperatures above about 600 F. to

was intentionally allowed to remain in the water. It is

prevent freezing. As a storage alternative, the 50 per-

not advisable to reduce the carbonate hardness to the

cent solution may be diluted to 25 to 30 percent

lowest possible value because such water will be corro-

2-20

Previous Page

Previous Page