*TM 5-813-1/AFM-88-10, Vol. 1

5-3. Types of Wells

Wells are constructed by a variety of methods. There is

no single optimum method; the choice depends on size,

depth, formations encountered and experience of local

well contractors. The most common types of wells are

compared in table 5-1.

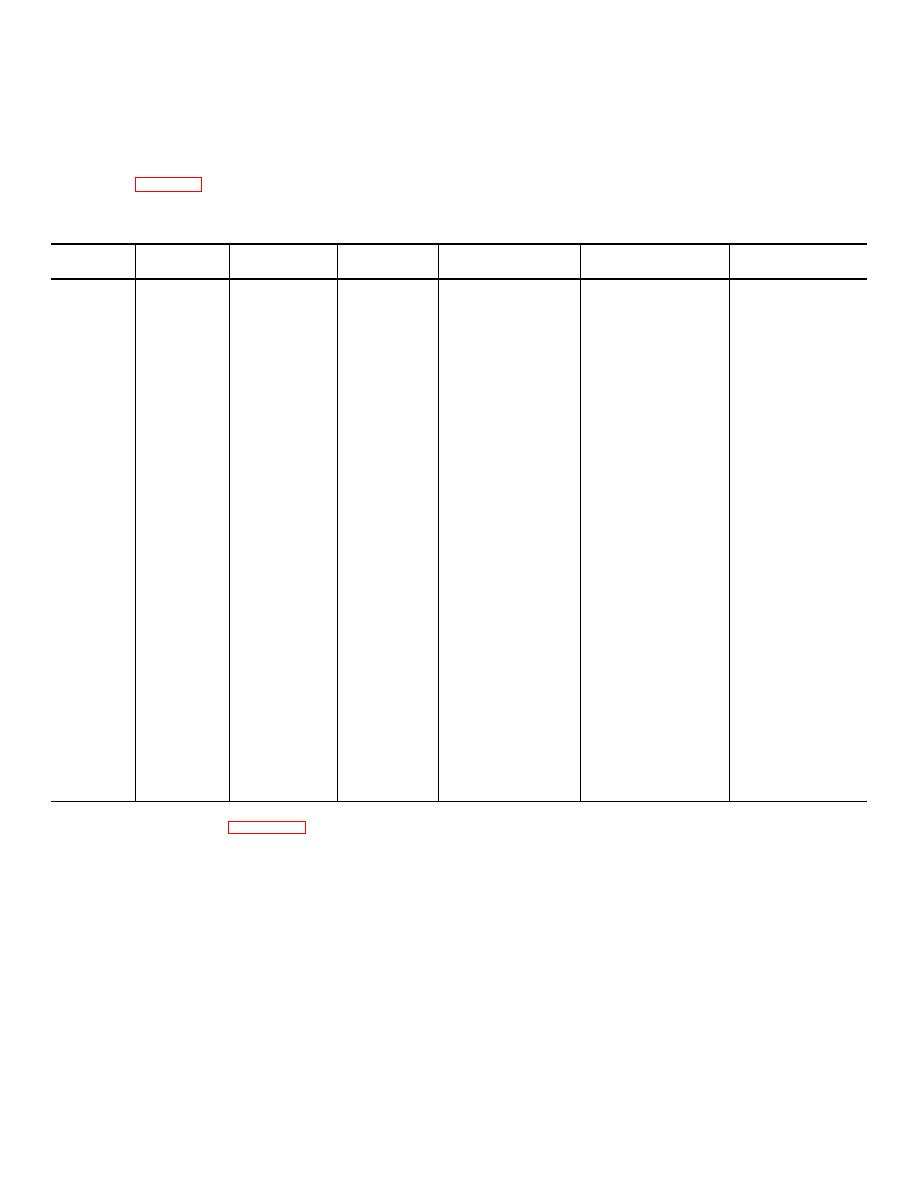

Table 5-1. Types of Wells.

Maximum

Lining or

Method of

Type

Diameter

Depth (ft)

Casing

Suitability

Disadvantages

Construction

Dug

3 to 20

40

wood, ma-

Water near sur-

Large number of

Excavation from

feet

sonry, con-

face. May be con-

manhours required

within well.

crete or

structed with

for construction.

metal

hand tools.

Hazard to diggers.

Driven

2 to 4

50

pipe

Simple using

Formations must be

Hammering a pipe

inches

hand tools.

soft and boulder

into the ground.

free.

Jetted

3 or 4

200

pipe

Small dia. wells

Only possible in

High pressure

inches

on sand.

loose sand forma-

water pumped

tions.

through drill pipe.

Bored

up to 36

50

pipe

Useful in clay

Difficult on loose

Rotating earth au-

inches

formations.

sand or cobbles.

ger bracket.

Collector

15 feet

130

Reinforced

Used adjacent to

Limited number of

Caisson is sunk

concrete

surface recharge

Installation Con-

into aquifer. Pre-

caisson

source such as

tractors

formed radial

river, lake or

pipes are jacked

ocean.

horizontally

through ports

near bottom.

Drilled

Up to 60

4000

pipe

Suitable for vari-

Requires experi-

a. Hydraulic ro-

inches

ety of forma-

enced Contractor &

tary*

tions.

specialized tools.

b. Cable tool per-

cussion*

c. reverse circula-

tion rotary

d. hydraulic-per-

cussion

e. air rotary

*For detailed description, see Appendix C.

5-3

Previous Page

Previous Page