TM 5-818-5/AFM 88-5, Chap 6/NAVFAC P-418

1

C

d2/ d1

0.604

1.002

0.25

1.004

0.30

0.605

0.606

1.006

0.35

0.606

1.013

0.40

0.607

1.033

0.50

1.072

0.60

0.608

0.70

0.611

1.146

0.643

1.301

0.80

1.706

0.90

0.710

(Courtesy of Fairbanks Morse, Inc., Pump Division)

Note: The diameter of the orifice should never be larger than 80

percent of the pipe diameter in order to obtain a satisfactory pres-

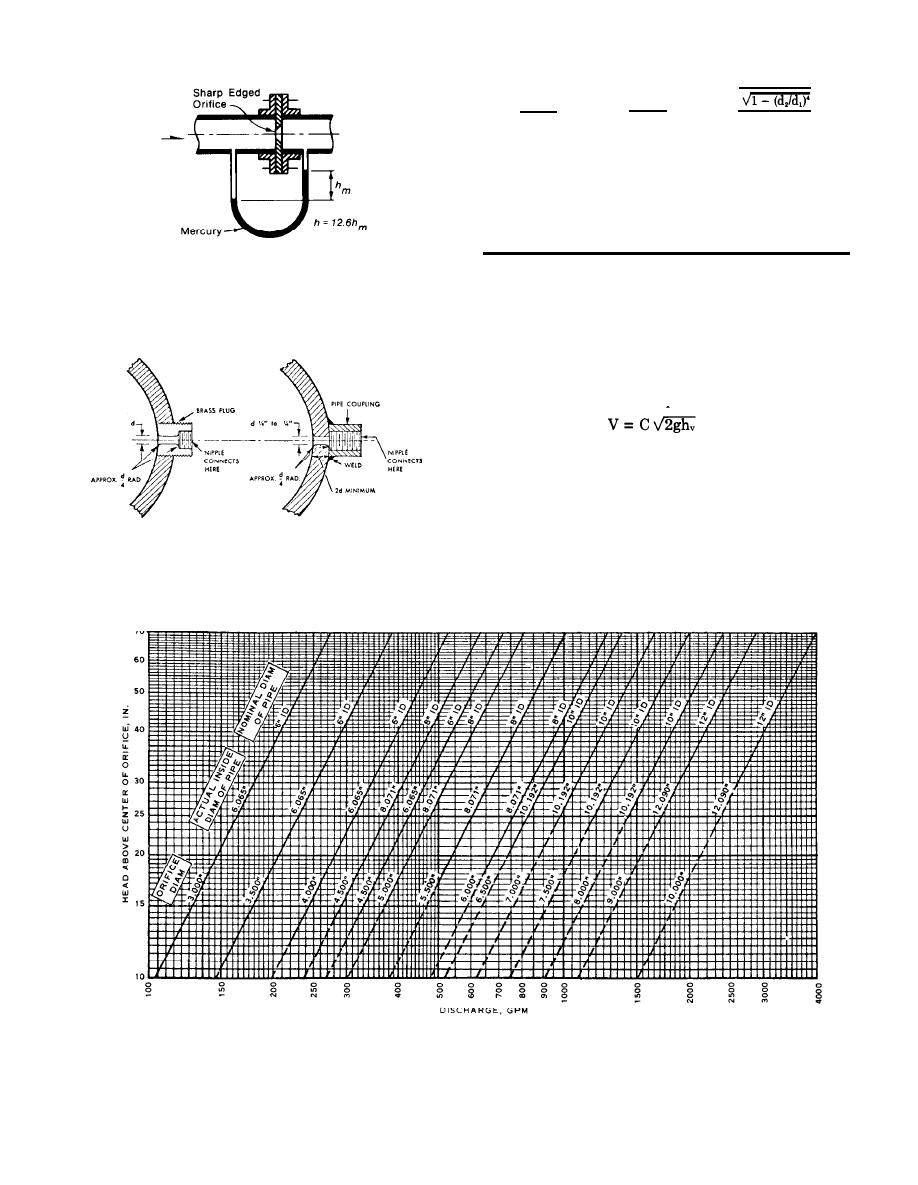

Figure F-3. Orifice in pipe.

sure reading.

c. Pitot tube. The flow in a pipe flowing full can also

be determined by measuring the velocity at different

locations in the pipe with a pitot tube and differential

manometer, and computing the flow. The velocity at

any given point can be computed from

(F-3)

where

V = velocity

C = meter coefficient

g = acceleration of gravity

h = velocity head

The flow is equal to the area of the pipe A times the

(Courtesy of Fairbanks Morse, Inc., Pump Division)

average velocity V, or

(F-3a)

Q = AV

Figure F-4. Approvedpressure taps.

(Courtesy of Fairbanks Morse, Inc., Pump Division)

Figure F-5. Pipe cap orifice chart.

F-2

Previous Page

Previous Page