TM 5-815-5/AFM 88-5, Chap 6/NAVFAC P-418

APPENDIX F

WELL AND TOTAL DISCHARGE MEASUREMENTS

F-1. General. The simplest method for determin-

b. Orifices.

ing the flow from a pump is to measure the volume of

(1) The flow from a pipe under pressure can be

the discharge during a known period of time by collect-

conveniently measured by installation of an orifice on

ing the water in a container of known size. However,

the end of the pipe (fig. F-2), or by insertion of an ori-

this method is practical only for pumps of small capac-

fice plate between two flanges in the pipe (fig. F-3).

ity; other techniques must be used to measure larger

The pressure tap back of the orifice should be drilled at

flows.

right angles to the inside of the pipe and should be per-

fectly smooth as illustrated in figure F-4. A rubber

F-2. Pipe-flow measurements.

tube and glass or plastic pipe may be used to measure

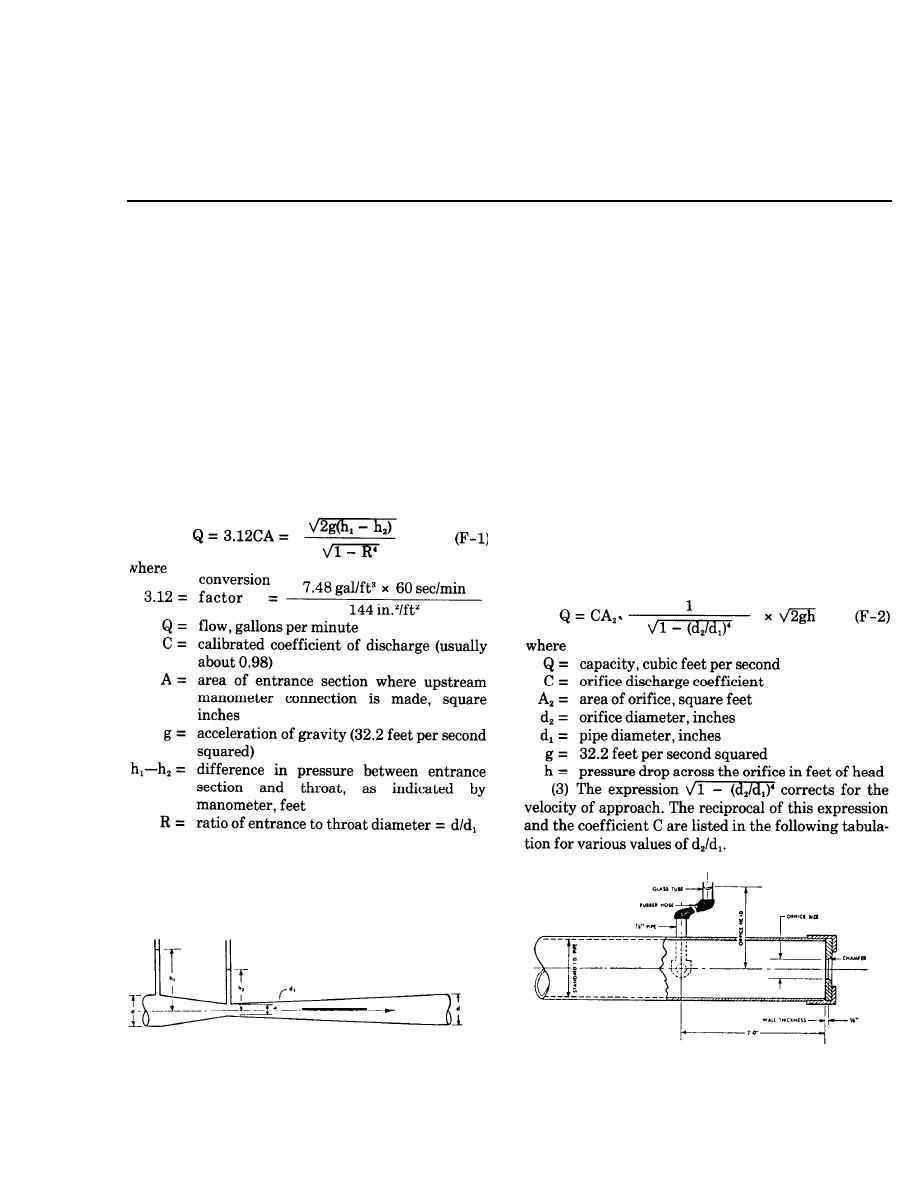

a. Venturi meter. The flow from a dewatering sys-

the pressure head. The diameter of the orifice plate

tem can be accurately measured by means of a venturi

should be accurate to 0.01 inch; the edge of the plate

meter installed in the discharge line. In order to obtain

should be square and sharp, should have a thickness of

accurate measurements, the meter should be located

/8 inch, and should be chamfered at 45 degrees as

1

about 10 pipe diameters from any elbow or fitting, and

shown in figure F-2. The approach pipe must be

the pipe must be flowing full of water. The flow

smooth, straight, and horizontal; it must flow full, and

through a venturi meter can be computed from

the orifice should be located at least eight pipe diam-

eters from any valves or fittings. The flow for various

sized cap orifice-pipe combinations can be obtained

from figure F-5.

(2) The flow through an orifice in a pipe can be

computed from

The pressures h1 and h2 may be taken as illustrated in

figure F-1 for low pressures, or by a differential mer-

cury manometer for high pressures. Gages may be

used but will be less accurate.

(Courtesy of Fairbanks Morse. Inc., Pump Division)

(Courtesy of Fairbanks Morse. Inc., Pump Division)

Figure F-1. Venturi meter.

Figure F-2. Pipe cap orifice.

F-1

Previous Page

Previous Page