TM 5-818-5/AFM 88-5, Chap 6/NAVFAC P-418

(Courtesy of Layne & Bowler, Inc., Memphis, Tenn.)

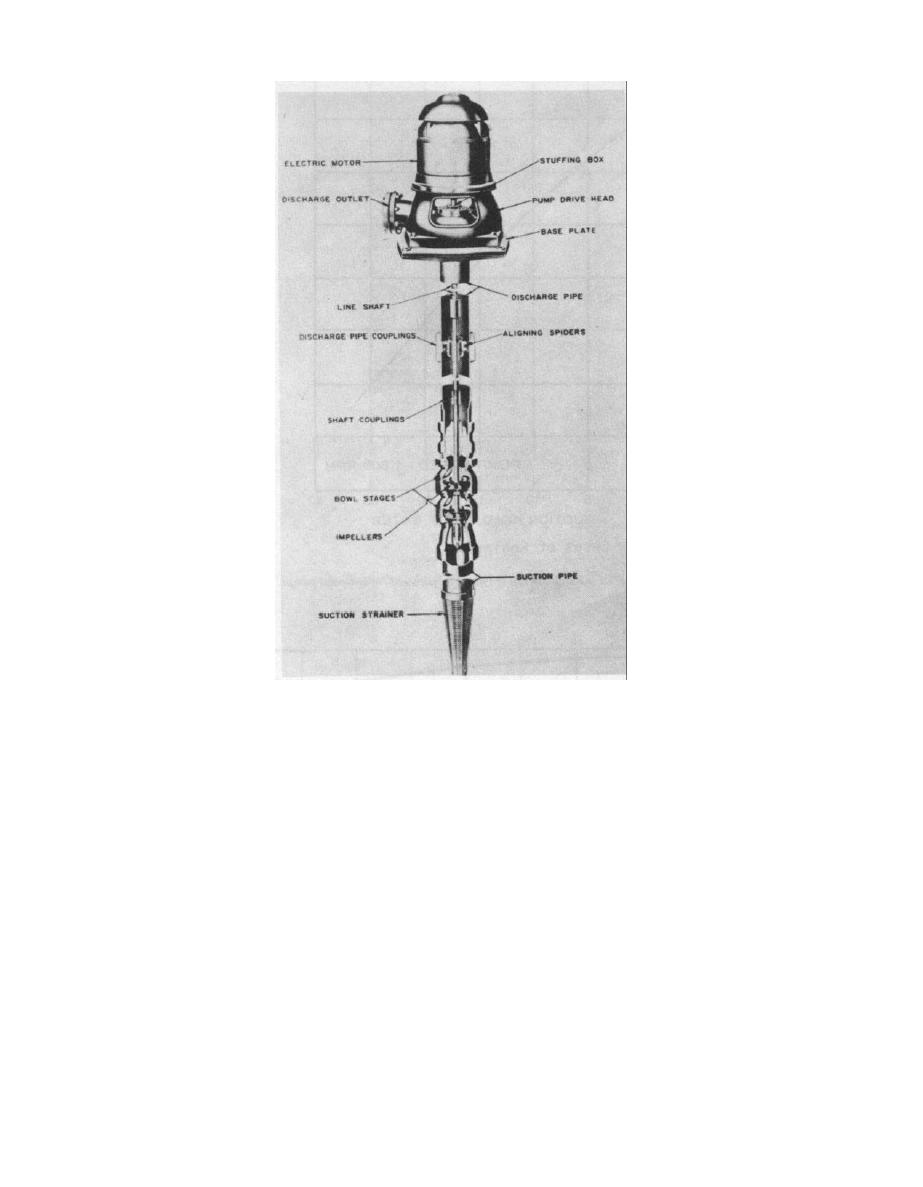

Figure 4-34. Deep-well turbine pump.

of operation in event of pump or engine failure, or for

b. Deep-well pumps.

repair or maintenance. By overdesigning the header

(1) Deep-well turbine or submersible pumps are

pipe system and proper placement of valves, it may be

generally used to pump large-diameter deep wells and

possible to install only one standby pump for every

consist of one or more stages of impellers on a vertical

two operational pumps. If electric motors are used for

shaft (fig. 4-34). Turbine pumps can also be used as

powering the normally operating pumps, the standby

sump pumps, but adequate stilling basins and trash

pumps should be powered with diesel, natural or LP

racks are required to assure that the pumps do not be-

gas, or gasoline engines. The type of power selected

come clogged. Motors of most large-capacity turbine

will depend on the power facilities at the site and the

pumps used in deep wells are mounted at the ground

economics of installation, operation, and maintenance.

surface. Submersible pumps are usually used for

It is also advisable to have spare power units on site in

pumping deep, low-capacity wells, particularly if a

addition to the standby pumping units. Automatic

vacuum is required in the well.

switches, starters, and valves may be required if fail-

(2) In the design of deep-well pumps, consider-

ure of the system is critical.

ation must be given to required capacity, size of well

4-38

Previous Page

Previous Page