EI 02C097

01 Jul 97

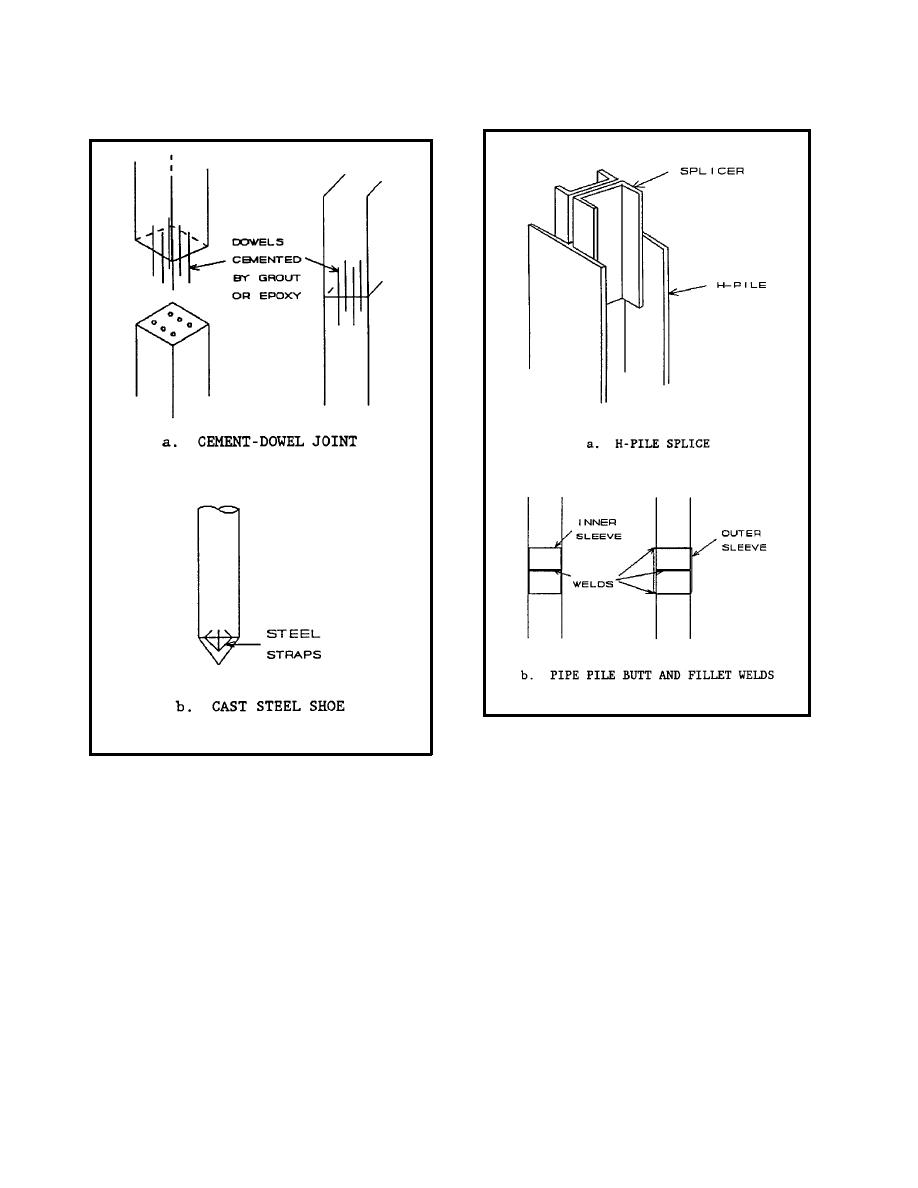

Figure 1-3. Steel pile splices

Figure 1-2. Concrete pile splice and boot

may not be suitable when tolerance is small with respect to

location and where absolute plumbness is required. Table 1-3

significantly affected by corrosion in undisturbed soil.

lists commonly available H-piles together with properties and

Schematics of H-piles and pipe piles are presented in

dimensions.

Figure 1-3.

(b) Steel pipe piles. Commonly used steel pipe piles are

listed in Appendix B together with properties and dimensions.

(a) Steel H-piles. This type can carry larger loads, both

Steel pipe piles are generally filled with concrete after driving

axially and in bending, than timber piles and can withstand

to increase the structural capacity. If the soil inside the pipe is

rough handling. H-piles can be driven into dense soil, coarse

removed during driving, open-end piles in cohesionless soil

gravel, and soft rock with minimum damage, and cause

will cause less soil displacement and compaction, and in

minimal displacement of the surrounding soil while being

cohesive soils will cause less heaving of adjacent ground and

driven. Hardened and reinforced pile tips should be used

nearby piles. If the soil inside the pipe is not removed during

where large boulders, dense gravel, or hard debris may damage

driving, the pipe becomes plugged and acts as a closed-end

the pile. Splices are commonly made with full penetration butt

displacement pile. Criteria are presently unavailable for

welds or patented splicers (Figure 1-3a). H-piles can bend

computing the depth at which a driven, open-end pile will plug.

during driving and drift from planned location. Thus, H-piles

In cases where the foundation contains boulders, soft rock, or

1-6

Previous Page

Previous Page