CEMP-ET

TI 809-53

01 May 1999

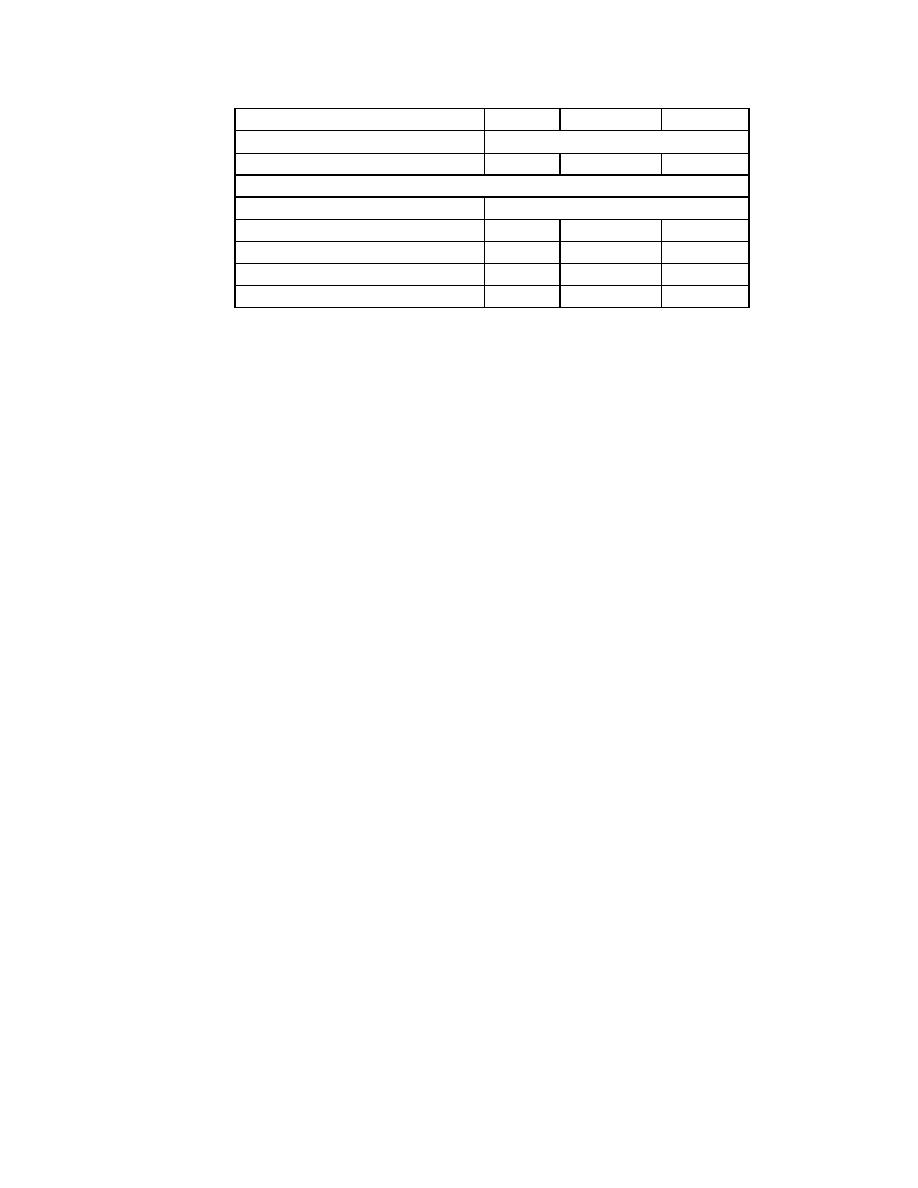

2.7

6.2

1.1

SPF

Batts and Blankets

Rock/Slag/Glass

1.5

3.5

0.53

R value varies with in-place density

Loose Fill Insulations

Cellulose (milled paper)

2.8

2.3

0.40

Expanded Perlite

5.6

4.1

0.72

Rock/Slag/Glass Fibers

1.5

0.6

0.10

Vermiculite, Exfoliated

7.6

7.0

1.23

Note: Thermal resistance (R=1/C where C = k/thickness). The higher the

thermal resistance, the more efficient the insulation. Resistance may decline

with age due to diffusion of air into foam cells (aging of foam). Absorption of

water can reduce the insulating ability of most insulations to a small fraction of

their dry value.

(2) Installation Locations. Thermal insulation may be installed in four locations.

(a) Underdeck insulation (figure 2-15).

1/ Wood frame structures with steep roofing often utilize batt insulation placed

between the rafters. Vapor retarders of foil, kraft, or plastic film are located on the inside face of

the insulation. With structural standing seam metal systems, batts are draped over the purlins. In

attics, the insulation is usually positioned between ceiling joists.

2/ An advantage of underdeck insulation is that inexpensive nonstructural

insulations such as batts may be used.

3/ A disadvantage is that the roof deck suffers greater thermal stress than when

it is overlaid with insulation. Another disadvantage is that it is difficult to vapor seal such

construction and make it resist air exfiltration and as a result moisture problems are prone to

occur. Ventilation is usually required but ventilating low-slope framed roofs lacking tight air

barriers is apt to increase moisture problems, not eliminate them.

4/ Common underdeck materials include compressible batts of glass fiber and

mineral wool. Thermal spacers of rigid plastic foam are placed over the purlins of SSSMR

systems to maintain the thermal resistance where the batts are compressed.

(b) Self-insulating roof deck (figure 2-16):

1/ Insulating decks such as structural wood fiber are less popular today

because it is difficult to achieve high R values within the deck itself. In reroofing situations

supplemental insulation would often be added on top of such a deck. In some new assemblies a

composite of structural wood fiber topped with plastic foam is used. The underside of these self-

insulating decks can be exposed to the interior and serves as an attractive acoustical ceiling.

(c) Thermal insulation within the roofing sandwich (figure 2-9).

1/ Insulation on top of the roof deck is the most common configuration for

membrane roofing. For adhered membrane systems the thermal insulation restrains the

membrane against wind loss or shrinkage and must have adequate structural strength. For

mechanically anchored and ballasted systems compressive strength and stability are important. If

2-23

Previous Page

Previous Page