CEMP-ET

TI 809-53

01 May 1999

carefully sealed with tape. Puncturing the retarder, either accidentally or by installing mechanical

fasteners lessens its resistance to moisture.

(6) PMRs. Protected Membrane Roofing systems (PMR's) are very effective against

vapor drive from within the building. The roof membrane itself serves as the vapor retarder as

most, if not all, of the thermal insulation is located above it. Self-drying of the insulation (extruded

polystyrene) to the atmosphere maintains the thermal resistance.

(7) SPF Systems. SPF systems are commonly installed on re-cover installations where

the old bituminous membrane can be sealed to form a retarder. Dew point calculations are

necessary to insure the dew point is within the upper SPF layer.

(8) Steep Roofing. In steep roofing systems the retarder is usually a plastic film (poly),

treated kraft paper or foil facing on batt insulation installed with the retarder facing the interior.

When an attic or cathedral ceiling is present, ventilation of the space above the insulation is

essential since retarders are rarely completely sealed and some moisture accumulation would

otherwise occur. Most codes recommend at least 1:150 net free ventilation area (total at eave

and ridge) when a retarder is not installed to 1:300 when a retarder is in place. In cathedral ceiling

construction larger net free areas are needed since friction losses in the narrow airway reduce

ventilation.

(9) Metal Systems.

In structural metal systems where draped batt insulation is

used, it is difficult to completely seal the retarder facer even if tape is used. When high interior

vapor conditions exist the use of a subdeck to support a retarder film may be necessary. Other

roofing systems should also be considered as such systems are not good at resisting high

internal relative humidities.

f. Considerations When Using Thermal Insulation. Thermal insulation is important in

modern buildings both for energy conservation and human comfort and may impact roof

membrane performance.

(1) Thermal Resistance. Resistance to heat flow through the entire roof structure

(characterized by the R factor) should be as high as is both practicable and cost effective. In

general the Corps of Engineers recommends an R factor of > 20 (Rsi > 3.57). Note: U = 1/R

therefore, the U factor should be < 0.05 Btu/hrft2 oF (0.284 w/m2 oK).

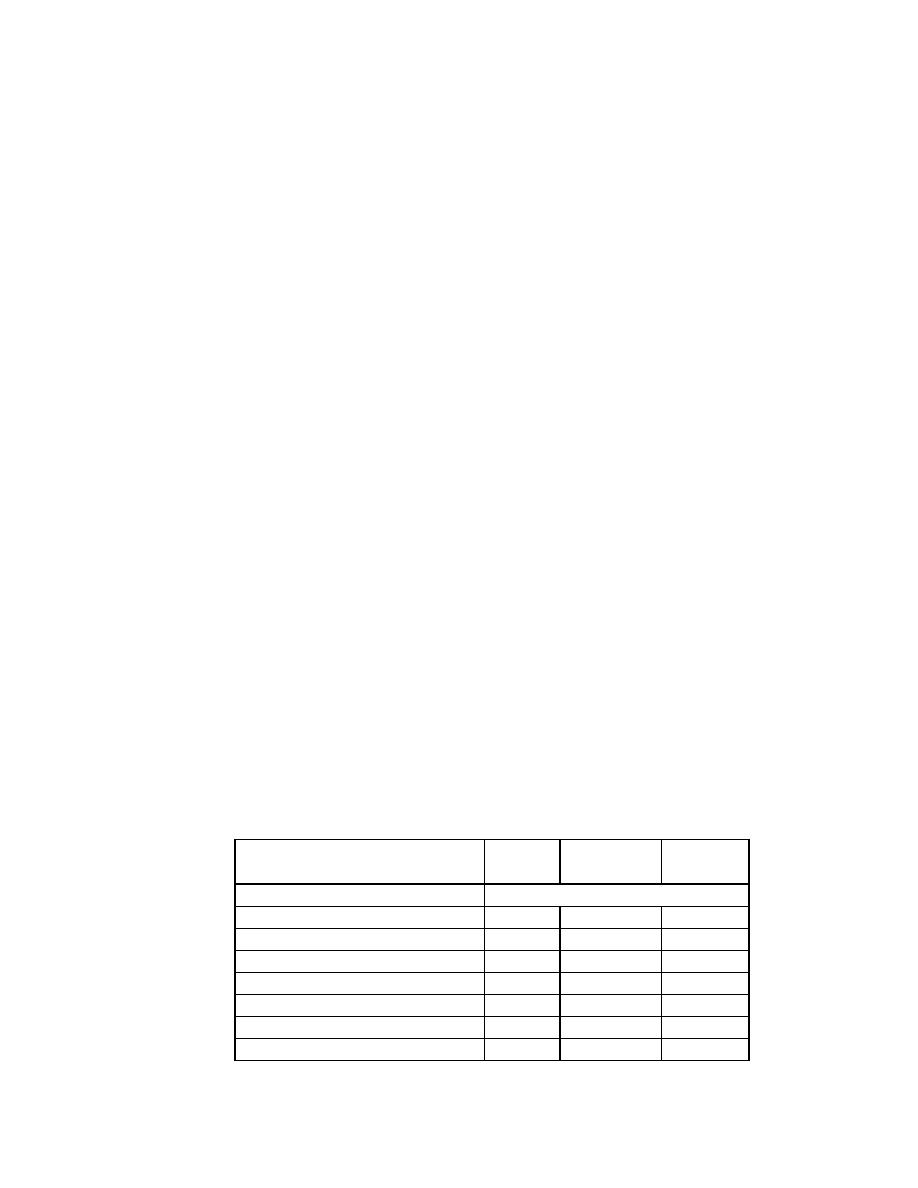

Table 2-16. Unit Resistances (i.e., Resistivity) of Common Roof Insulations

R/Inch

WoC/m2

Density

(HroF/btu)

(pcf)

Rigid Boards

Rigid Polyisocyanurate Foam

2.0

6.2

1.1

Extruded Polystyrene Foam (XEPS)

2.2

5.0

0.88

Glass Fiber Boards

14

4.0

0.73

Expanded Polystyrene Foam (MEPS)

1

3.8

0.67

Foamed Glass

9

2.9

0.50

Expanded Perlite

10

2.8

0.49

Wood Fiber

18

2.8

0.49

2-22

Previous Page

Previous Page